Repair aluminum wiring using the AlumiConn™ pigtail & splicing connector

Repair aluminum wiring using the AlumiConn™ pigtail & splicing connector

Reduce the Risk of Aluminum Wiring

Fires

- POST a QUESTION or COMMENT about how to repair aluminum electrical wiring to reduce the risk of overheated connections or building fires

AlumiConn™ splice connector installation: this article describes the acceptable methods to repair aluminum wiring when using the AlumiConn™ splicing connector to connect copper to aluminum wires and aluminum-to-aluminum wires.

We describe how to make aluminum to copper pigtail connections using the COPALUM connector or the AlumiConn™ connector as well as how to make aluminum-to-aluminum wire connections and aluminum ground wire connections. For safe aluminum wiring repairs, readers must follow the manufacturer's instructions provided by King Innovations, the AlumiConn manufacturer as well as recommendations from the US CPSC for aluminum wiring repair.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

How to Make Aluminum Wiring Repairs Using the AlumiConn™ Splice Connector

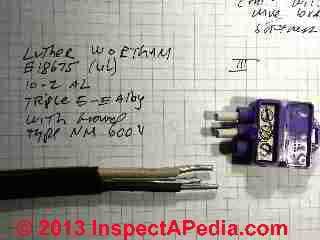

AlumiConn TM Purple #95135 aluminum to copper lug connectors[1],

new in 2006, U.L. Listed, 2007, have completed independent testing,and are now US CPSC recommended as of 2011. These connectors are available from King Innovation and at building & electrical suppliers.

AlumiConn TM Purple #95135 aluminum to copper lug connectors[1],

new in 2006, U.L. Listed, 2007, have completed independent testing,and are now US CPSC recommended as of 2011. These connectors are available from King Innovation and at building & electrical suppliers.

[Click to enlarge any image]

Results of independent testing indicate that this product "... is predicted to have a high probability of failure-free long-term safe performance, PROVIDED THAT THE SETSCREWS ARE CAREFULLY TIGHTENED TO THE MANUFACTURER'S RECOMMENDATION".

The AlumiConn™ connector shown here is used to splice a copper "pigtail" wire together with one or two aluminum wires as a step in reducing the fire hazard associated with aluminum electrical wiring. This connector performs well provided that the wires are properly secured in the connector, and it has been included in the US CPSC recommendations for aluminum wiring repair.

Installation Instructions for the AlumiConn Aluminum to Copper Lug (AL-CU)

Installation Instructions for the AlumiConn are simple and involve just four steps:

- Strip conductors 5/16"

- Insert conductor into wire port, fully seating conductor into port

- Tighten set screws to the torque indicated below, based on conductor size and material as indicated.

[See AlumiConn TORQUE SETTINGS] - Once all conductors are installed,close lid taking care to verify latch is securely fastened.

Caution: not following recommended torque instructions can result in failure.

These easy instructions do not however address real-world trouble that comes up in any electrical wiring retrofit or repair job such as avoiding damage to the existing finished wall surfaces, connector torquing challenges, finding space to fit the original device (receptacle, light switch etc) into the electrical box along with original wires, pigtail copper wires, and splicing connectors, and how to handle ground wires.

We address these practical concerns in this article and in in-depth articles linked to from the text below.

Watch out: this article (below) provides additional in-depth details about using the AlumiConn connector for splice repairs to aluminum electrical wiring. For a safe proper installation follow the complete AlumiConn installation instructions provided by the manufacturer and also found at

- The AlumiConn website - www.kinginnovation.com/products/alumiconn/ has installation videos, Wire combinations, specification sheets, and other information and assistance in purchasing or using this product.

- The AlCopSTOREis an independent website where you can also purchase the AlumiConn™ aluminum wiring connector.

Reference: details of the study and recommendations are on page #6 (the 9th page in the .pdf file) in Dr. J.A. Aronstein's .pdf document version of "Reducing the Fire Hazards in Aluminum Wired Homes" May 21, 2007. The test results are completed and will be published in September 2007. (100 connectors cost $285. Lower prices for larger quantities.)

Where to Buy the AlumiConn connector

- The AlumiConn website - www.kinginnovation.com/products/alumiconn/ has installation videos, Wire combinations, specification sheets, and other information and assistance in purchasing or using this product.

- The AlCopStore [link given above] is an independent website where you can also purchase the AlumiConn™ aluminum wiring connector.

- Home Depot and other building supply stores

- Electrical wiring & equipment suppliers

Technical notes on Installing or Wiring the AlumiConn™ for aluminum wiring repair

Installation instructions for AlumiConn™ for aluminum wiring repair

Installation details & notes are found in this article just below where we will provide important details about installing and torquing the AlumiConn™connector for successful aluminum wiring repair.

- Aluminum Wire Repair Connector Space Problems in junction boxes and receptacle boxes:

at ALUMINUM WIRE REPAIR SPLICE SPACE we discuss options for fitting the AlumiConn™ connector and/or COPALUM and the necessary copper pigtail wires into electrical boxes where space is tight. The NEC makes an exception to connector count and wire count and space limitations to permit the use of these connectors for aluminum wiring repairs. - Field installation experience, installation time, pigtail lengths are discussed

at ALUMINUM WIRING REPAIR FIELD NOTES - practical advice & field experience using the AlumiConn™ connector - Aluminum ground wires: don't forget that not only original solid aluminum the hot and neutral conductors but also the aluminum ground conductor need to be treated.

See ALUMINUM GROUND WIRES for additional wiring details and an example using the AlumiConn™.

Torque settings for the AlumiConn™ Splice Connector

Torque specifications (discussed here) for the AlumiConn are particularly important for this particular connector as it involves tightening a screw in a terminal block to secure the aluminum or copper wire being spliced.

Torque specifications (discussed here) for the AlumiConn are particularly important for this particular connector as it involves tightening a screw in a terminal block to secure the aluminum or copper wire being spliced.

This connector can be used to join wire types & sizes as follows

AlumiConn™ Splice Connector Wire Sizes |

| #18 - #10 Solid & Stranded Copper |

| #12 - #10 Solid Aluminum |

Aronstein emphasized that the connector's acceptable performance relied on using the proper torque settings.[3] King Innovations provides two installation methods, depending on whether or not you own a torque-screwdriver.

Our photo (left) shows the bit of a torque screwdriver inserted into the screw in the AlumiConn™ terminal block.

Watch out: the manufacturer makes clear that their installation instructions for the AlumiConn without using a torque-setting screwdriver are not included in the CPSC recommendations, but the " manufacturer (King Innovation) stands firmly behind this installation method." [1]

Torque settings for the AlumiConn™: Reading the UL document we found no mention whatsoever of torque specifications - those are particularly important for this particular connector as it involves tightening a screw in a terminal block to secure the aluminum or copper wire being spliced. Aronstein emphasized that the connector's acceptable performance relied on using the proper torque settings.

Aluminum wire repair AlumiConn™ torque settings are described just below in this article and are also found at the AlumiConn site - you'd need the $100. SK SK 73004 torque measuring screwdriver to install these connectors - costly, but much less so than renting the COPALUM crimping tool and becoming certified to use it. Our photo at above-left shows the SK 73004 torque setting screwdriver with the hex wrench installed to permit setting the desired torque reading on this tool.

Our photo at above-left shows the SK 73004 torque setting screwdriver with the hex wrench installed to permit setting the desired torque reading on this tool.

Our photo at left shows the 15 inch-pound setting on the SK 73004 torque measuring screwdriver [provided courtesy of King Innovations - Ed].

The "alternative method" described by the manufacturer for tightening the screws produces torque close to or exceeding the actual torque specified numbers (according to some preliminary tests we have done in our lab) - photo at left.

But we are not confident that that approach would be adequate for general field use where individual human performance may vary considerably.

For example, you may not be exactly sure just when the setscrew "... comes into contact with the solid conductor". King is confident of this approach but is careful to point out that it is not associated with the UL listing for the product.

The AlumiConn™ Torque settings specified by King Innovation

AlumiConn™ Aluminum to Copper Lug (AL-CU) Torque Settings for UL-Listed Application & Installation |

|

| #12 Solid Aluminum | 10 in-lb |

| #10 Solid Aluminum | 15 in-lb |

| All solid & stranded copper conductors | 15 in-lb |

Notes to the table above

Manufacturer approved alternate torque method for us on solid wiring only (not associated with UL listing): using a screwdriver, tighten screw set until it comes into contact with the conductor. Note location of the screwdriver slot and continue tightening the set screw as indicated below:

1 turn - #12 - #10 Solid Aluminum wire

1/2 turn - #16 - #10 Solid Copper wire

Caution: not following recommended torque instructions can result in failure.

Finally, King always recommends that installers to check the connection security by giving a quick tug on the wires to make sure they are tight.

Adapted from AlumiConn™ Purple #95103 #18AWG - #10 AWG package information.

Also see AlumiConn TORQUE TESTS - where independent test compares measured torque with the manufacturer's alternative torque method of counting screw turns

Technical note on binding and poor wire connections in aluminum terminal blocks & aluminum wire repairs

In larger-sized electrical wire connector applications such as electrical panel buses (not this product), we have saw (prior to 2011) aluminum-block connection failures occur when the steel screw bound in the aluminum block, appearing to be a tight connection before proper contact with the wire has been made.

Mr. King informed us that they have addressed this concern by plating the screws in nickel and plating the lug block in tin, thus eliminating the galling found in other lugs. Also there is a very small gap at the back of the wire terminal block where the installer can see the wire (coated in sealant) coming through. This provides visual confirmation that the wires came all the way through.

Junction box / receptacle box space limitations & aluminum wire repairs

As we introduced in discussing the COPALUM, the AlumiConn™ connectors and the copper pigtail wires also take up more space in a junction box or receptacle box than the original wires and connectors. The manufacturer informs us that the AlumiConn™ and the COPALUM are similar in the space these devices require.

at ALUMINUM WIRE REPAIR SPLICE SPACE we discuss options for fitting the COPALUM connector or the AlumiConn™ connector along with copper pigtail wires into electrical boxes where space is tight.

at ALUMINUM WIRING REPAIR FIELD NOTES we discuss practical field experience using the AlumiConn™ connector along with copper pigtail wires into existing electrical boxes and describe the installer's opinions about optimum pigtail wire working length and installation time requirements.

Safety & Usability of the AlumiConn™: 4 Points of Discussion

1. Independent tests showed that IF the Alumiconn connector is properly installed (including torquing to the proper torque setting) it performs as well as COPALUM. We have absolute confidence in Dr. Aronstein in this matter - he is fully qualified, experienced, and is an unbiased independent party with no financial connection to the company selling Alumiconn (nor to any one else selling other products).

Here is Aronstein's paper on the topic: Reducing the Fire Hazards in Aluminum-Wired Homes - 5/21/07, (AlumiConn™ info is on p. 9)

The Alumiconn™ is UL listed (UL 486C) as a "pressure type screw connector" (USA) and CSA approved (Canada) for aluminum wiring repairs.

For general information about that listing type, see this UL connector information On the UL listing for wire connectors.

2. U.S. CPSC: This connector performs well provided that the wires are properly secured in the connector, and it has been included in the US CPSC recommendations for aluminum wiring repair as of approximately June 2011.[2][3]

3. Torque settings for the AlumiConn™: Reading the UL document we see no mention whatsoever of torque specifications - those are particularly important for this particular connector as it involves tightening a screw in a terminal block to secure the aluminum or copper wire being spliced. Aronstein emphasized that the connector's acceptable performance relied on using the proper torque settings.

Torque settings are described at AlumiConn TORQUE SETTINGS

The "alternative method" described by the manufacturer for tightening the screws produces torque close to or exceeding the actual torque specified numbers (according to some preliminary tests we have done in our lab) - photo at left.

In a separate article, AlumiConn TORQUE TESTS describes an independent test comparing torque results using a torque-measuring screwdiver, the SK 73004 torque measuring screwdriver [provided courtesy of King Innovations - Ed] and the manufacturer's alternative torque setting method that involves counting the number of screw turns past first contact.

4. UL listing vs CPSC Recommended: So if you were working for someone else and wanted to install only the CPSC-recommended connectors, you'd use only the AMP/TYCO COPALUM™ method or the AlumiConn™.

In March 2010, prior to the CPSC recommendation of AlumiConn™ connectors for aluminum wiring repairs, we (DJF) presented this information for a group of 50 licensed electricians at an Aluminum Wiring Repair Methods Update - class [power point presentation[ in Dallas TX. These were trained licensed electricians who are informed and conservative in their practice.

The company's position was that they would not use an connector that was not CPSC-recommended, notwithstanding its UL listing.

Indeed, some products carrying a UL listing for aluminum wiring repair have been shown to perform very poorly in the field, such as CU/AL devices and the Ideal65 purple "Twister" connector sold for

-

WALL-NUTS [New U.S. product application, Not UL Listed, undergoing testing before UL application]

spring-clamp terminal blocks available from Wago Corporation have is being tested by that company for

a connector for aluminum-to-copper pigtailing for aluminum wiring repair.

WALL-NUTS [New U.S. product application, Not UL Listed, undergoing testing before UL application]

spring-clamp terminal blocks available from Wago Corporation have is being tested by that company for

a connector for aluminum-to-copper pigtailing for aluminum wiring repair.

The company informs us that a similar product use with aluminum wire conductors has been approved and used in Europe for over 20 years. The company is conducting further testing before submitting the product to UL to obtain a listing.

Significantly, the company indicates that this connector is suitable for connecting multi-stranded (copper) as well as solid conductor conductors. If approved by UL and if test results are satisfactory, this product would, in addition to providing standard solid CU to solid AL connections, address the wiring of a twisted-copper-wire light fixture to a solid conductor aluminum branch circuit wire.

This connector has not been recommended, nor recommended against, by the US CPSC, and is currently undergoing testing. Results will be reported here ASAP. Product description information for the copper to copper wire connection use of this connector is available at the Wago website.

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2022-04-14 by Inspectapedia Com Moderator - Wago twist on connectors are NOT RECOMMENDED for aluminum wire repair

@Craig Nelson,

Thank you for the Wago question.

Wago twist on connectors are NOT RECOMMENDED for aluminum wire repair.

Those connectors have never been recommended nor accepted by independent authorities or experts.

Prior to development of the AlumiConn and the AMP-TYCO Crimp Connector for aluminum wiring repair, Aronstein had researched and demonstrated that with careful abrading of newly stripped aluminum wire, abraded *through* the antioxidant, some twist-on connectors performed reasonably well.

That procedure is described in detail at

SCOTCHLOK 3M REPAIR CONNECTORS

However even that expert would now be the first to say that method should NOT be used. The currently recommended methods for AL wire repair are in this article series and are recommended as the ONLY two methods for aluminum wire repair (by the U.S. CPSC):

the Amp TYCO Crimp connector

The AlumiConn connector

Separately, and for use only on ALL-COPPER wiring, we do describe use of Wago

at WAGO WIRE SPLICING CONNECTORS

There you'll see that we cited the company's assertion that the Wago Wall-Nuts might be used to repair aluminum wire, but they have never been UL listed and CPSC approved for aluminum wire repair in the United States.

HOWEVER: Wago DOES describe use of "Wall Nuts" for aluminum-to-copper pigtailing, at the company's web page found at

www.wago.com/us/electrical-installers/practical-tip-connecting-aluminum-and-copper-conductors

I found it a little confusing: here's an excerpt:

Junction Box and Building Distribution Board Connections

With WAGO Alu-Plus Contact Paste (20 ml syringe), solid aluminum conductors up to 4 mm² can also be connected with WAGO's 2273 Series PUSH WIRE® Junction Box Connectors and 222 Series Splicing Connectors up to 4 mm² per the standards. However, the 221 Series is not approved for this. But the 224 Series Lighting Connectors can also be used with this paste. “In building distribution boards, all CAGE CLAMP®-equipped rail-mount terminal blocks up to 4 mm² can reliably connect aluminum and copper conductors with the Alu-Plus contact paste. These terminal blocks include the 279 to 281 and 780 to 781 Series.“

See a copy of Wago's ALUMINUM and COPPER CONNECTIONS - WAGO [PDF] (2020)

Watch out: OPINION: electricians will want to be careful using ANY connector for aluminum wiring repair if that connector is not recommended by the US CPSC. Should there later be a fire loss traced to the building's wiring system, both electricians and building owners may find that their fire insurance coverage may be constrained or not applicable.

Watch out: OPINION: although it's a technical detail, the Wago authors of the document we cite make me nervous because they don't have or at least don't express anywhere near an accurate account of the cause of aluminum conductors overheating and fires.

The authors cite moisture but in fact Aronstein proved that micro-fretting - very small electrical arcing at the connector - is the actual cause of oxidization and heat build up in resistance at the connector that in turn can cause overheating sufficient to ignite a fire.

QUOTING:

The Problem: Fire Hazard

Connecting aluminum and copper conductors is like a boxing match: in one corner is the resilient and inexpensive lightweight aluminum (Al). In the other corner, the superconductive and more expensive standard copper (Cu). If a conductive liquid (such as water condensation) is added to the fight, an electrochemical reaction occurs: the copper decomposes the aluminum, increasing contact resistance and temperature. This mixture could result in a fire.

Continuing: IMO that is not an accurate description of the cause of aluminum wiring overheating and fires.

So sure, moisture may be a factor but it's not an accurate explanation of the aluminum electrical wiring hazard.

On 2020-07-30 by Craig Nelson

It has been many years now since the above comments about Wago Wall-Nuts, specifically the 773 and 2273 series of push wire connectors. It was stated that testing was underway and that results would be posted ASAP. I now see UL listing for the 773 series and they seem an ideal aluminum wiring solution (particularly the 2273 series).

When can we expect an update or is an update available somewhere?

On 2022-04-14 by Inspectapedia Com Moderator - Can I use the AlumiConn lugs with the stranded aluminum wire in a 70 year old house?

@Hugh,

No, Hugh, for two reasons:

1. the AlumiConn is only sized for use with #12 or #10 solid aluminum conductors

2. Your 70A stranded aluminum wire is not only stranded, it also will be much larger: 3-gauge

The AlumiConn CAN be connected to stranded COPPER conductors, however, as we read in this excerpt from the current product specifications that you can find at

ALUMICONN CONNECTOR SPECIFICATIONS & INSTALLATION GUIDE [PDF] https://inspectapedia.com/aluminum/AlumiConn-Specifications-2022.pdf

Tighten set screws to the torque indicated below, based on conductor size and material as

indicated.

10 in-lb #12 solid aluminum

15 in-lb #10 solid aluminum

15 in-lb all solid and stranded copper conductors

On 2020-08-28 by Hugh

Can I use the AlumiConn lugs with the stranded aluminum wire in a 70 year old house? I find no guidance from anyone, anywhere.

On 2022-04-14 by Inspectapedia Com Moderator - Is there an antioxidant in the splice kit?

@Sparky Stumpy,

See this AlumiConn specifications sheet from its producer, King Innovations

ALUMICONN ALUMINUM to COPPER LUG

That contains these installation instructions:

UL LISTED INSTALLATION INSTRUCTIONS

IMPORTANT: Turn off power before installing or removing connector.

Product to be used in accordance with local and national codes.

1. Strip conductors 5/16”.

2. Insert conductor into wire port, fully seating conductor into port.

3. Tighten set screws to the torque indicated below, based on conductor size and material as indicated. 10 in-lb #12 solid aluminum

15 in-lb #10 solid aluminum

15 in-lb all solid and stranded copper conductors

Do not over torque.

4. Once all conductors are installed, close lid taking care to verify latch is securely fastened.

Not following recommended torque instructions can result in failure.

To be sold only with installation instructions.

Note that there is no use of antioxidant.

On 2022-04-13 by Sparky Stumpy

Is there an Anti-Oxidant in the splice kit?

On 2020-07-12 - by (mod) - using an AlumiConn to connect a ceiling fan to aluminum wired circuit

Carlos: you do not need to add that extra pigtail or piece of wire.

In the article above in the table

AlumiConn™ Splice Connector Wire Sizes

you will see that the AlumiConn accepts these wire sizes

#18 - #10 Solid & Stranded Copper

and

#12 - #10 Solid Aluminum

So you'd insert your aluminum power source into one connector opening

and you'd insert your copper fan wire into another connector opening ** IF ** your copper fan wire is in the acceptable size range #18 - #10 Solid & Stranded Copper - which it probably is.

Thank you for asking a helpful question. Don't hesitate to follow up, and I'd also like to see photos of your connections (you can post one photo per each comment)

On 2020-07-12 by Carlos

I will be installing a ceiling fan to aluminum wire, can I run the hot feed wire Of the house into one of the alumicon port and the hot wire of the fan into the other port or do I need to run a piece of wire from the alumicon port to the hot wire of the fan?

On 2016-07-18 - by (mod) - Don't use Marrett connectors for aluminum wiring repair

Doug:

Just to be clear, InspectApedia.com is a public information website. To protect the trust of our readers, we do not sell anything and we have no financial connection with services, products, or materials discussed here.

You'll see in the article above that King Innovation's AlumiConn can be used to connect up to 3 conductors (Since this original article the company may have expanded its product line to include larger connectors, I don't know). You might give the company a call to ask about number of wires as well as sizes.

Because of poor field performance, connector failures, fire risks, the "purple wire nut" you describe and that is sold for aluminum wire repairs, is NOT RECOMMENDED by independent authorities and experts including the US CPSC. see inspectapedia.com/aluminum/Ideal_65_Twister_History.php

Other than re-wiring, for recommended repair connectors, in addition to the AlumiConn discussed in the article above,

On 2016-07-17 by Doug

What connection is made when I'm a 2 or 3 gang switch box you have 4 or 5 neutral or hot wires twisted together. The connector you sell only has 3 lugs and according to videos I've seen the purple wire nut is only good for 1 al. Wire and 1 cu. Wire connected together.

Some light fixture boxes may have 4 or 5 Romex wires coming into them. What connection is used?

Very interesting site. I have a a 40 year old wood frame house 100 amp service with mostly aluminum wiring

. I have been in the house for 30 years. I was aware of some of the connection problems with aluminum wiring especially for full load circuits. As such I have pulled the duplex receptacles in the kitchen and workshop and the electric range to tighten the screw connections and look for any cooking at the Marrett connections.

I have used a number of copper pigtails using appropriate AL/Cu Marretts and antioxidizer grease. I have not been scrupulious to get back to unoxidized Al but I do a full spiral twist of the conductors before applying the Marrettes. I have had ver little issue with the wiring except for the two outdoor receptacles that were used for full load devices such as a bbq starter and electric lawn mower.

Both of these indicated heat damage at the receptacle. I would be very interested in using the AlumiConn connectors but have been unable to find out if they have a CSA approval marking on them.

The Marretts do and from an insurance point of view using connectors without a CSA approval will void my home insurance. Do the 2 and 3 port AlumiConn connectors have a CSA approval stamp on the connector?

...

Continue reading at AlumiConn TORQUE TESTS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ALUMINUM WIRING IDENTIFICATION

- ALUMINUM WIRING REPAIR METHODS

- ALUMINUM WIRING REPAIR ELECTRICIANS

- ALUMINUM WIRING REPAIRS NOT-RECOMMENDED

- REDUCE THE AL WIRE RISK: DETAILS

Suggested citation for this web page

AlumiConn INSTALLATION PROCEDURE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ELECTRICAL INSPECTION & TESTING

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- AlumiConn website - www.kinginnovation.com/products/alumiconn/ has installation videos, Wire combinations, specification sheets, and other information and assistance in purchasing or using this product.

- [1]AlumiConn [Website: AlCopStore.com ] ™ AlCopStore.com 223 Salt Lick Road, #279, St. Peters, MO 63376

Tel: 866-826-2256, Fax: 636-754-0500, Email Sales: pking@AlCopStore.com, Email General Inquiry: info@AlCopStore.com - [2] "Repairing Aluminum Wiring," [As updated 2011] U.S. Consumer Product Safety Commission Publication available online

- [3] "Record of Commission Action, Commissioners Voting by Ballot", CPSC Publication No. 516, Repairing Aluminum Wiring (original version op.cit.), (Briefing package dated March 15, 2011), Quoting:

The Commission voted unanimously (5-0)·to approve republication of CPSC Publication No. 516, Repairing Aluminum Wiring, with the explicit recognition that the COPALUM and AlumiConn connectors currently are the only products that meet the agency's standards to prevent aluminum wire fire hazards

Copy on file as /aluminum/Pub516_Alumi_Conn.pdf - [4] Dr. Jess Aronstein, protune@aol.com is a research consultant and an electrical engineer in Schenectady, NY. Dr. Aronstein provides forensic engineering services and independent laboratory testing for various agencies. Dr. Aronstein has published widely on and has designed and conducted tests on aluminum wiring failures, Federal Pacific Stab-Lok electrical equipment, and numerous electrical products and hazards. See ALUMINUM WIRING BIBLIOGRAPHY and see FPE HAZARD ARTICLES, STUDIES for examples.

- [5] "The Influence of Corrosion Inhibitor and Surface Abrasion on the Failure of Aluminum-Wired Twist-on Connections", Aronstein, J.; Campbell, W., Components, Hybrids, and Manufacturing Technology, IEEE Transactions on Volume 7, Issue 1, Mar 1984 Page(s): 20 - 24

- "Aluminum Wiring: Understanding the Problem and Its Solutions", Hartford Insurance Company - NOTICE: this information contains technical errors and some obsolete information. We include the document reference as an indication of insurance companies who are aware of aluminum electrical wiring hazards and costs. Aluminum Wiring: Understanding the Problem and Its Solutions", Hartford Insurance Company - local copy.

- 05/21/2007 Reducing the Fire Hazards in Aluminum-Wired Homes, [.pdf document], Jess Aronstein, Ph.D., 21 May 2007. This document answers most technical questions about the hazards and remedies of aluminum electrical wiring and includes a report on independent test results of alternative products and methods for repairing aluminum wiring. Some of the sections of this very thorough document are listed below:

- 02/09/2006Reducing the Fire Hazards in Aluminum-Wired Homes, Jess Aronstein, Ph.D., This older version of the above document also answers most technical questions about the hazards and remedies of aluminum electrical wiring

but lacks latest repair product testing such as the AlumiConn connector discussed above. Some of the sections of this very thorough document are listed below:

[UPDATED-DF 03/08/2003, Edits-df 02/09/2006]

Pigtailing using COPALUM - CPSC recommended,

Pigtailing using Scotchlok 3M - superceded by new alternate repair as of June 2007 - a tested, usable aluminum wiring connector method, with a link to step-by-step "how to" photos,

Pigtailing using Ideal 65 - NOT RECOMMENDED, aluminum wiring failures research, field and lab experience, expert sources. - WANTED: Aluminum Wiring Field Reports, Photographs, Samples, & Failure Cases & Data for ongoing study on frequency and severity of occurrence of problems. If you have experienced any problem, or symptom of possible problem with aluminum electrical wiring, or have repaired or replaced it, please contact the InspectApedia Editor All information is confidential. Study results will be provided to the U.S. Consumer Product Safety Commission and to the electrical industry. Real life aluminum wiring field failure reports can be seen at Aluminum Wiring Failures in Residential Properties: Field Reports & Pictures.

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.