Asbestos in Plastics & Bakelite

Asbestos in Plastics & Bakelite

History, Manufacture & Identification of Asbestos Containing Plastics & Molded Materials

- POST a QUESTION or COMMENT about what building materials may contain asbestos, visual identification of asbestos-containing materials in buildings, and possible asbestos material identification by testing, use, age, appearance

This article series about asbestos plastics & molded materials describes the history, manufacturing process & uses of asbestos plastics and molded materials such as asbestos reinforced handles, the Vanguard rocked nose cone, automobile parts & housings, electronic equipment (radar scanner), asbestos-filled Teflon, rocket motor parts, plastic drop tanks for the Hawker Sea Hawk, and hundreds of other products.

Page top photo: the asbestos-plastic drop tank for the Hawker Sea Hawk - Adapted from Rosato (1959) .

This articles series about the manufacture & use of asbestos-containing products includes detailed information on the production methods, asbestos content, and the identity and use of asbestos-containing materials.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Asbestos Plastics: Manufacture, Uses, History

Summary of Current Regulation of Use of Asbestos in Plastics

Summary of Current Regulation of Use of Asbestos in Plastics

Depending on the country where plastic products were or are produced, the last-used-date for asbestos in plastic and resinous products varies, and technically the use of asbestos in plastics is currently legal.

See details

at ASBESTOS PRODUCTS BANNED vs PERMITTED U.S. 2023

Really? Does this mean that plastics necessarily do contain asbestos? Are those products dangerous?

Keep in mind that asbestos reinforced plastic products are not friable.

Unless you are grinding, chopping, sanding or sawing such materials they will not release meaningful amounts of asbestos fibers in normal use.

What follows here is a history of the use of asbesstos in reinforced and filled plastic products such as Bakelite and Noramite and other plastic materials from door handles to rocket nosecones - which you will read is a very large category.

Introduction to the Production & Uses of Asbestos-Reinforced Plastics & Molded Products

The following text is Adapted from Rosato (1959) p. 142-177 [1] © 2013 InspectApedia.com

Introduction Asbestos reinforced and filled plastics have played an important role in the progress of the growth of industry since the turn of the century.

[Click to enlarge any image]

Since the development of phenol-formaldehyde resins in 1909, asbestos has been used in large quantities as a reinforcement, additive, and filler. There have been large quantities of short asbestos used in plastics such as those shown in Figure 9.1. Figure 9.2 shows the use of long fiber asbestos in asbestos-reinforced plastic rocket nose cones.

Figure 9.1. Typical difficult molding of long handle which has a hollow center to accommodate the electrical thermostat and wiring for Dominion skillet. - Courtesy Durez Plastics Div., Hooker Electro-Chemical Co.

Plastic materials are available which can be reinforced with such different fibers as asbestos, glass fiber, glass flakes, cotton, and Fiberfrax. These varied fibers provide for either different characteristics or in some cases, they can produce equivalent properties for specific applications.

The review in this chapter concerns only asbestos reinforced plastics.

Generally, when reviewing the subject of asbestos filled or reinforced plastics, phenolic resins or condensation type resins are discussed.

However, asbestos is used with such other resins as those listed in Table 9.1. Asbestos fibers, and in particular short fibers, are used in combinations with such other fibers (including long asbestos fibers) as polyester premix compounds.

Figure 9.3 below shows an automobile air conditioning housing which is made up of 55 per cent by weight of asbestos shorts or floats, 10 per cent chopped glass fiber, and 35 per cent polyester resin (with styrene). An extremely large quantity of asbestos fibers is used with these types of compounds but in most cases they are not identified as containing asbestos.

Plastics is one of the few billion dollar industries in the United States. It is one of the fastest growing industries with approximately a 300 per cent increase in production in the last ten years. The term "plastics" pertains to many different products.

Asbestos is used in many of them. In most applications it provides for meeting property requirements at low cost. As the plastic industry grows, more use of asbestos also develops both in thermoplastic and thermosetting resins.

| SOME USES OF ASBESTOS IN PLASTIC COMPOSITIONS * TABLE 9.1 | ||

|---|---|---|

| Type of Asbestos-Containing Resin | Products & Applications Using This Asbestos Plastic Resin | Method of Fabrication of the Asbestos-Plastic Resin Product |

| Rosin, with or without waxes,

gilsonite, creosote, shellac,

mineral oils, phenolic resins,

etc. |

Electrical insulations |

Hot molding, chilling |

| Shellac, with rosin, creosote,

lime, etc. |

Electrical insulations and miscellaneous

uses |

Hot molding, with or without chilling |

| Asphalts, tars and pitches, with chlorinated rubber, oils, solvents, etc. | Heat insulator coatings for metal pipes Parts for electrical and heat appliances | Brushing Drying, cold molding, using waterproofing molding |

| Waxes (Montan, carnauba, etc.) with shellac, natural resins, gilsonite, modified rosins, mineral oils, etc. | Casting, coating, molding Box toe compositions Roofings |

Hot molding, chilling Hot molding, chilling Hot pressing, chilling |

| Polymerizable oils | Joints, coating compositions, etc. | Brushing, trowelling, etc., curing |

| Rubber or chlorinated rubber, with or without alkyd resins, etc. with or without organic filler and asbestos | Brake linings, clutch facings, valve discs,

gaskets, packings, etc. |

Hot molding, curing |

| Phenolics, alone or with natural resins, rubber, inorganic filler (silica or mica) and asbestos, floats, long fiber, paper, yarn or fabric | Laminated boards |

Hot pressing Hot molding Hot molding Curing |

| Molded heat resistant compositions Impregnated sheets, panels, or boards, gaskets, valve discs, etc. Asbestos fabric pressed as blocks Asbestos sheet as spacers for heat insulators Asbestos yarns, etc. for clutch facings, etc. |

Hot molding Laminated under heat and pressure Heat and pressure Hot pressing Hot molding |

|

| Cellulose esters | Asbestos and cellulose esters used to in- crease strength and toughness of glycerol phtholate molding compounds |

|

| Alkyd resins | Commutator rings Mica sheets Brake linings Door stripes, electrical spools, etc. Structural tiles Wood veneer panels Acid proof coatings |

Hot molding, chilling, curing Hot molding, chilling Cold molding, curing |

| Phenolic varnishes | To increase adherence to coated surface,

to increase flexibility of undercoatings,

on metal surfaces, also used in

packings, putties and boards |

Varies depending on application |

| Sheet protection for metal surfaces | Asbestos paper or sheet is connected to metal surface by phenolic resin and

then coated with the same material |

Curing by heat and pressure |

Notes to the table above:

Typical uses of asbestos in plastic components - Rosato ca 1952

* A. B. Cummins, "Asbestos in Plastic Compositions" Modern Plastics.

Also see these pages from a 1950 catalog CAREY ROOFING CATALOG 1950 [PDF] describing asbestos plastic roof tiles.

Also see these pages from a 1950 catalog CAREY ROOFING CATALOG 1950 [PDF] describing asbestos plastic roof tiles.

Figure 9.2. Vanguard rocket nose cone is made of asbestos-phenolic material. It is subjected to aerodynamic heating, shock heat, and structural loads. The two-piece cone splits apart and drops off after the rocket leaves the atmosphere.

Applications of Asbestos-Reinforced Plastic Materials

Typical commercial applications of asbestos-plastic materials include pulleys, casters, electrical circuit breakers, pipes, roller and sleeve bearings, metal bearing retainers, bushings, containers, ducts, and washing machine agitators.

Architects and engineers are developing more uses for asbestos based plastics too, inasmuch as they provide for increased resistance to fire and increase structural strength.

Information concerning the impact-porosity resistance of - plastics is applicable to doors or paneling, containers, boats (hull and floor), radomes, pressure bottles or tubes, plywood surface, rocket tubes, decorative panels, and ducts. Asbestos sheet products can be used on the surface, in the center or interleaved with other reinforcements to provide for high impact-porosity resistance.

The impact-porosity resistance of glass fabric or glass woven roving-polyester resin laminates is increased threefold when glass fabric is interleaved and/or surfaced with asbestos felts or papers. *

One of the more important and spectacular applications of asbestos reinforced plastics involves its use in missiles. Its insulation, ablation, and fine structural characteristics are all required in order that parts may function properly. Special asbestos-base plastics have been developed for use in direct rocket blasts which in turn have helped solve some of the high temperature problems.

Parts which are involved in the use of this type of product include nose cones, thermal - insulation barriers between propellant and steel motor bodies, rocket exhaust tubes, electrical conduits, aft insulators, deflector plates, rocket motor pressure plugs, turbine wheels, ducts, bulk head, fins, shrouds, and sliver traps. See Figures 9.8 through 9.10 inclusive.

* U.S. Navy, Bureau of Ships, Final Report, "The Use of Asbestos Fiber Materials in Glass Reinforced Plastic Laminates," Project 4860-Q-27 NS034-045 (Aug., 1957).

Figure 9.8. The Nike-Hercules sustainer motor contains asbestos phenolic insulation from the forward end to the exhaust end. - Courtesy The Thiokol Corporation. Click this or any image at InspectApedia to see a detailed, enlarged version.

Figure 9.9. A rocket motor tube tailpipe fabricated from asbestos phenolic plastic. -Courtesy The Bristol Aeroplane, Ltd.

Figure 9.10. Rocket motor body asbestos-plastic exhaust cone and ring.

Experimental tests using temperatures as high as 20,000°F have been conducted on various asbestos products. The materials are very poor conductors of heat and therefore help to solve some of the thermal problems.

During their exposure to extremely high temperatures for short periods of time their surfaces will oxidize or carbonize and produce a protective outer surface. Ablation or erosion occurs at a relatively slow rate.

Various parts have been made by such different techniques

as compression molding, vacuum bag, autoclave, and transfer

molding. These plastic parts can be easily mass produced.

They have been used in modern development and

production devices.

Various parts have been made by such different techniques

as compression molding, vacuum bag, autoclave, and transfer

molding. These plastic parts can be easily mass produced.

They have been used in modern development and

production devices.

Figure 9.11. Asbestos base plastic 75-gal drop tank for the Hawker Sea Hawk. This tank is the first plastic drop tank in the world to have received full design approval.

The Bristol Aeroplane Company, Ltd., Filton, Bristol, England, has now received world wide acceptance of its asbestos-phenolic external auxiliary fuel tanks for aircraft.

This is the first world wide acceptance of any reinforced plastic part. These drop-tanks are shown in Figure 9.11.

They are required in large numbers and they form an important and costly item in modern air force inventory. The Bristol tank capacities are varied—SO, 100, 150, 200, 300, and 500 gal.

The Bristol tanks have been developed as a logical sequence to the company's work on plastics for primary structures.

The production techniques used, i.e., the molding of cylindrical fuselage sections by the autoclave process and the hydraulic press methods used for central sections and frames, have both been found to be readily adaptable to the manufacture of drop-tanks; the former process is used for the shell and the latter for the internal structure.

Newly developed [1950's - Ed.] high strength asbestos reinforced honeycomb is now in pilot-plant production. This new type of core material is the first of its kind where good physical properties at room and elevated temperatures are developed with asbestos. The presently available type utilizes a heat resistant phenolic resin.

Summary of preliminary properties of this type material identified as Hexcel Type XHRP % 6 —Asb.- 9.0 are shown in Table 9.11. A structural honeycomb utilizing silicone resin with asbestos reinforcement is in an early stage of development.

TABLE 9.11. ASBESTOS-PHENOLIC HONEYCOMB DATA * |

|||

| Flexural Shear, psi |

Compressive, flatwise, psi |

||

| Test Temperature | Ultimate Strength |

Modulus | Ultimate Strength |

| Room | |||

| L direction | 785 | 56,000 | 1,450 |

| W direction | 435 | 28,800 | |

| Tested at 500°F after 1/2 hr at 500°F |

|||

| L direction | 475 | 30,800 | 1,145 |

| W direction | 300 | 12,200 | |

Notes to the table above

In the early 1950's plastics, including asbestos-reinforced plastics, was one of the few billion-dollar U.S. industries and was growing at a rate of 300% over the prior decade. This table lists the types of asbestos-reinforced resins used and the products made with asbestos-plastics as well as the method of asbestos-plastic manufacture.

Shear Specimens 3 in. by 8 in. simple support over 6 in. span, core 5/8 in. thick with Al. facings .091 in. thick.

Compression Specimens 2 in. by 2 in., 5/8 in. thick core, Al facings .091 in. thick.

- Shear Specimens for asbestos phenolic honeycomb material 3 in. by 8 in., simple support over 6 in. span, core % in. thick with Al. facings .091 in. thick.

- Compression Specimens for asbestos phenolic honeycomb material 2 in. by 2 in., % in. thick core, Al facings .091 in. thick.

* Hexel Co. was an information source for the table above, published by Rosato (seeReferences or Citations for more about the Hexel Corporation).

Original Table as-published: TABLE 9.11 ASBESTOS-PHENOLIC HONEYCOMB DATA [Image File] in Rosato, Op. Cit.

Use of Asbestos Plastic in the 1951 Delta Aircraft Wing

In 1951, a Delta Aircraft wing made of asbestos-phenolic laminate was displayed at the Exhibition of the Society of British Aircraft Constructors at Farnsborough, England. The Royal Aircraft Establishment, Ministry of Supply provided the exhibit in order to show progress on reinforced plastic aircraft parts

. The wing was approximately 8 ft from the fuselage with approximately an lift chord at the root. The shell of the wing continued around a leading edge and over the whole area back to the ailerons. There were no outer skin joints.

Fabrication of the wing was accomplished by two techniques; i.e., zero pressure and vacuum technique. In the zero pressure process, asbestos-phenolic sheet material (Durestos) was saturated with warm water producing a very soft sheet which could be hand rolled into simple curvatures.

By applying heat, these sheets would tend to delaminate and to produce low physical properties. To eliminate this problem, the softened sheets were treated with a water-soluble, coldsetting resorcinol resin. This resin penetrates the material and produces a solid compressed sheet.

During the cure, the resorcinol resin shrinks. Inasmuch as one side of the molded material will be exposed to the air, water is free to evaporate. This method of fabrication is a specialized art; it is not a standard procedure.

The vacuum process is a more desirable method of fabricating parts at low pressure, inasmuch as it provides for the elimination of condensation formed during the curing of the phenolic resin. The phenolic pre impregnated asbestos sheet material is manufactured so that suitable flow and resin conditions exist for this type of fabrication.

A male or female mold is used in conjunction with a vacuum bag which is generally made of rubber.

Two different basic internal structures were manufactured for the Delta wing construction. One was designed to provide compartments for various equipment. The other design involved internal fuel tanks. Asbestos-phenolic plastics were used in the manufacture of a high performance experimental wing for a glider by the Plastics Division of F. G. Miles, Ltd., Shoreham Airport, Sussex, England (1953).

The wing was of the high-performance type, being designed for laminar flow and having an aspect ratio of 18.

The wing had a 60 ft span, a 5 ft chord at the root, and weighed 155 lb. This plastic type of wing had been manufactured inasmuch as a high degree of accuracy was required in the contour of the wing. This accuracy permitted the production of a low cost item as compared with the conventional methods of manufacture.

Companies Producing Asbestos-Containing Plastic Products

See our complete list of asbestos-product producing companies found

at ASBESTOS PRODUCING COMPANIES & TRUSTS

Where we give details about each of the companies below and where we also identify any asbestos-settlement trusts associated with them

- Allied Chemical & Dye

- American Petrofina

- Armstrong World Industries (floor tiles)

- Celotex (building products)

- Certainteed Corp. (building products, plastic cement)

- Combustion Engineering

- Flintkote (building products, Plastic Chrome Ore, Plastic K-N Refractory Cement, plastic insulation)

- Graylock Packing Co.

- Greene, Tweed & Co.

- Indianapolis Paint & Color Co.

- Kaiser (building products, Kaiser Gypsum plastic cement)

- Mobile Oil Co.

- National Gypsum (Gold Bond Plasticrylic, Plasticrylic Panels)

- Philip Carey (All-weather plastic cement, Plastic-asbestos cement)

- Plastics Engineering Corporation, PLENCO asbestos-containing products

- TBA Industrial Products Limited

- Tile-Tex Co.

- Union Carbide (Bakelite plastics containing asbestos filler & fibers)

- United Gilsonite Labs.

- W.R. Grace & Co.

Asbestsos, Bakelite, & Plastics Research

Editor's note:

The first truly synthetic plastic was created in 1907 by Leo Baekeland [Katz (1984)] from phenol formalde-

hyde and christened ‘bakelite’which is now known to degrade into acrylonitrile, butadiene, styrene,

cyanide and nitrous oxides which include irritants, suspected carcinogens and toxic respiratory system irritants [CAW (2003)

- Ables, Elden, Richard Bionta, Harlan Olson, Linda Ott, Eric Parker, Douglas Wright, and Craig Wuest. "ABS plastic RPCs." In Proceedings of the International Workshop on Resistive Plate Chambers and Related Detectors, Pavia p. 373. 1995. [Obsolte postscript file, hard to open, excerpting from search results:

... we were interested in materials with resistivities lower than the standard bakelite bulk resistivity of 1010-1011 ... Some materials heated up and melted un- der high voltage. ... Furthermore, because of the toxic fumes that it emits when burned, PVC poses an ES&H hazard - ALLEN, EG. "Plastic Materials and Fire Hazards (SEE PAGE 32)."]

- CAW 2003 HAZARDOUS SUBSTANCES - PLASTICS http://www.caw.ca/whatwedo/health&safety/factsheet/hsfssubstanceno35.asp

- Lucia, Arianna, Hendrikus WG van Herwijnen, and Thomas Rosenau. "Wood-based resins and other bio-based binders for the production of mineral wool." Holzforschung 74, no. 6 (2020): 539-550.

Introduction Excerpt:

Since phenolic resin was invented by Leo Hendrik Baekeland in 1907, launched with the iconic name of Bakelite, the product has started to revolutionize the plastic industry. The enormous field of applications goes from adhesives for wood and mineral wool, to the utili-zation for abrasive and friction passing through foundry and refractory functions. Phenolic resin is still one of the most important bonding agents with a ratio of cost to performance superior to most of the other polymeric resins (Pilato 2013).

- Sylvester-Bradley, Oliver. "Pernicious Plastics and the Precautionary Principle." [PDF] - quoting from search results: 'bakelite' which is now known to degrade into acrylonitrile, butadiene, styrene ...

a suspected endocrine disruptors and carcinogen [6]) and nylon (toxic if burnt [7]). Retrieved 1/23/2014, original source http://www.defactodesign.com/sites/default/files/Pernicious-plastics.pdf - PLASTIC or VINYL ODOR EXPOSURE [Web article]

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

Question: is there asbestos in this Aristocrat brand bakelite plastic saucepan handle?

Question: is there asbestos in this Aristocrat brand bakelite plastic saucepan handle?

(Feb 3, 2020) Tiiu Roiser said:

I have a question regarding old cooking pots, from probably the 1950's? I have several large and medium soup pots that have plastic-like handles. I have no idea what they may be made of.

The imprinted manufacturer says "Artistocrat". I've been reading about old bakelite. Might the handles be the same material and contain asbestos? I've been using these in the dishwasher.

The handles appear to be intact, but the black handles are disclouring to a dull gray.

Any idea what these might be? Is their use dangerous?

This Q&A were posted originally at ASBESTOS LIST of PRODUCTS.

Reply:

Tiiu,

Some hard plastics used asbestos so it's certainly possible.

The handle on your Aristocrat saucepan looks like and probably is Bakelite, a molded, hard thermoplastic.

I'm doubt that there's a detectable airborne asbestos hazard if you're not grinding or chopping up the material.

It's not friable.

Aristocraft [sic] or Aristocrat was a West Bend brand of stainless steel cookware still widely-available used and sold ask "vintage cookware".

West Bend, a Wisconsin company, was founded in 1911, sold to Regal Ware, another Wisconsin company in 2001, subsequently re-sold to Focus Products Group, LLC in 2003. The Regal Ware West Bend product line brand is still available under from West Bend Housewares, sold under the product names Lifetime and Royal Queen.

Bakelite Plastic Asbestos

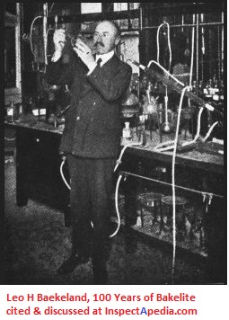

Bakelite plastics, including cookware handles, was produced by chemist Leo Baekeland in 1907. To produce a hard, durable thermosetting plastic, Dr. Baekeland used a mixture of wood fibers, asbestos fibers and asbestos dust or shorts, along with formaldehyde. (Baekeland 1910)

Asbestos in Bakelite was included as both filler and reinforcement. The asbestos shorts (small asbestos fragments) in Bakelite helped prevent shrinkage as the heat-molded thermoset plastic cooled.

Bakelite was very widely used in an enormous range of products beyond cookware, including electrical components, handles ( & knobs on furnaces and other hot objects, radios, TVs, and other electrical applications) and other consumer goods, and parts used in vehicles and weapons, even rocket parts as we discuss above on this page.

As we said above, Bakelite, though it contains asbestos, is not friable, is considered of low toxicity, and is not a banned substance.

Watch out: similar hard plastic products produced using other formulations may contain asbestos too, such as forms of PVC (PolyVinyl Chloride) products, products using phenolic plastics and even some nylon plastic products.

History of Bakelite & Hazards of Asbestos in Hard Plastics

[Click to enlarge any image]

Photo: Leo H. Baekeland, inventor of Bakelite, in 100 Years of Bakelite, the Material of 1000 Uses, Crespy et als 2008, cited below.

- Baekeland, Leo H. THE SYNTHESIS, CONSTITUTION, AND USES OF BAKELITE [PDF] Industrial & Engineering Chemistry 1, no. 3 (1909): 149-161. available from ACS Publications, pubs.acs.org.

Excerpts: So after all, the synthesis accomplished in my laboratory seems to have a decided similarity to some intricate biological processes that take place in the cells of certain plants.

In order not to increase too much the length of this paper, I have merely given you the brief outlines of years of arduous but fascinating work, in which I have been ably helped by Mr. Nathaniel Thurlow and more recently also by Dr. A. H. Gotthelf, who attended to my analytical work.

The opened field is so vast that I look forward with the pleasure of anticipation to many more years of work in the same direction. I have preferred to forego secrecy about my work relying solely on the strength of my patents as a

protection.

It will be a great pleasure to me if in doing so, I may stimulate further interest in this subject among my fellow chemists and if this may lead them to succeed in perfecting my methods or in- crease still further the number of useful applications of this interesting compound. - Baekeland, Leo H. "Bakelite, a condensation product of phenols and formaldehyde, and its uses." Journal of the Franklin Institute 169, no. 1 (1910): 55-60.

Abstract

Bakelite is a liquid compound of phenol and formaldehyde which on solidification resembles amber in appearance and when used in combination with wood, paper, asbestos, graphite and other substances produces a solid non-resistant, non-inflammable insulating material which promises to have many applications in various industries.

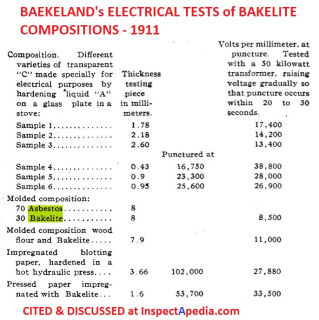

Illustration: table illustrating electrical test results performed by Baekeland on Bakelite of various compositions in Industrial & Engineering Chemistry 3, no. 12 (1911) cited below.

- Baekeland, L. H. RECENT DEVELOPMENTS in BAKELITE [PDF] Industrial & Engineering Chemistry 3, no. 12 (1911): 932-938. [Addresses]

Excerpt:

My subject involves the use of two main raw materials, phenol or carbolic acid, which is found in gas tar, and formaldehyde. The latter is now manufactured by the oxidation of wood alcohol.

I should state that the name of formaldehyde is used in rather a broad sense. I never have seen real formaldehyde (CH2O), and very few chemists have had occasion to examine it. It is a gas which can be made to liquefy and solidify by the intense artificial cold attainable by means of liquid air. ...

I found that we can enormously increase the practical uses of Bakelite by incorporating it with structural fillers, like fibrous or cellular bodies.

...

Molded compositions of ordinary asbestos and Bakelite, containing less than one-third of Bakelite, have shown on the Riehle testing machine tensile strengths as high as 4490 lbs. per square inch, and by selecting carefully the fibrous material still better results can be obtained.

[Note in the table copied from this presentation the ratios of Asbestos 80 and Bakelite 30, and the mention of wood flour and bakelite. This presentation discusses in detail the use of asbestos in Bakelite. - Ed.] - Crespy, Daniel, Marianne Bozonnet, and Martin Meier. "100 Years of Bakelite, the Material of a 1000 Uses." Angewandte Chemie International Edition 47, no. 18 (2008): 3322-3328.

- Cummins, A.B., "Asbestos in Plastic Compositions", A.B. Cummins, Modern Plastics [un-dated, pre 1952]

- Egilman, David S. "The production of corporate research to manufacture doubt about the health hazards of products: an overview of the Exponent Bakelite™ simulation study [PDF] International journal of occupational and environmental health 22, no. 1 (2016): 18.

- Egilman, David, and Tess Bird. "Short fiber tremolite free chrysotile mesothelioma cohort revealed." American journal of industrial medicine 59, no. 3 (2016): 196-199.

Disclosure statement

David Egilman serves as an expert witness at the request of persons injured by asbestos and asbestos product manufacturing companies who have been sued in asbestos personal injury tort litigation. He also served as a consultant to UCC in the Bhopal MIC chemical explosion of 1984.

This article has been retracted. Retraction in: Int J Occup Environ Health. 2016 January; 22(1): 18 This content has been removed by the publishers. - Egilman, David. THE PRODUCTION OF CORPORATE RESEARCH TO MANUFACTURE DOUBT ABOUT THE HEALTH HAZARDS OF PRODUCTS: AN OVERVIEW OF THE EXPONENT BAKELITE® SIMULATION STUDY [PDF] NEW SOLUTIONS: A Journal of Environmental and Occupational Health Policy 28, no. 2 (2018): 179-201.

Abstract:

Although corporate sponsorship of research does not necessarily lead to biased results, in some industries, it has resulted in the publication of inaccurate and misleading data.

Some companies have hired scientific consulting firms to retrospectively calculate exposures to hazardous products during use that are no longer manufactured or sold.

As an example, this paper reviews one such study—a litigation-generated study of Union Carbide Corporation’s asbestos-containing product, Bakelite®. This analysis is based on previously secret documents, produced as a result of litigation.

The study generated asbestos fiber exposure measurements which resulted in underestimates of actual exposures to create doubt about the hazards associated with manufacture and manipulation of Bakelite®.

Declaration of Conflicting Interests

The author(s) declared the following potential conflicts of interest with respect to the research, authorship, and/or publication of this article: Dr. Egilman testifies as an expert witness in asbestos litigation at the request of injured parties and asbestos product manufacturing companies. He served as an expert witness at the request of Union Carbide in the Bhopal litigation. - Hexcel Corporation (NYSE: HXL) is a public company that produces advanced composite materials (engineering).

The company develops and manufactures structural materials including carbon fiber, specialty reinforcements, resins, honeycomb, adhesives, engineered honeycomb composite structures, and prepregs (and other fiber-reinforced matrix materials).[4] Hexcel is a company resulting from the combination of California Reinforced Plastics (founded 1946), Ciba Composites (acquired 1995) and Hercules Composites Products Division (acquired 1995).

The company sells its products in commercial, military and recreational markets for use in commercial and military aircraft, space launch vehicles and satellites, wind turbine blades, sports equipment and automotive products. Hexcel works with major companies including Airbus Group, The Boeing Company, and others.[6] Since 1980, the firm has publicly traded on the New York Stock Exchange under the ticker symbol HXL.

Hexcel is headquartered in Stamford, Connecticut, and has offices and manufacturing facilities in Europe, Asia, North and South America, Russia, and Africa. - Wikipedia entry for Hexcel, retrieved 2017/07/11, original source https://en.wikipedia.org/wiki/Hexcel - Mowat, Fionna, Michael Bono, R. J. Lee, Susan Tamburello, and Dennis Paustenbach. "Occupational exposure to airborne asbestos from phenolic molding material (Bakelite) during sanding, drilling, and related activities." Journal of occupational and environmental hygiene 2, no. 10 (2005): 497-507.

Abstract:

In this study, a historical phenolic (Bakelite) molding material, BMMA-5353, was tested to determine the airborne concentrations of asbestos fibers released during four different activities (sawing, sanding, drilling, and cleanup of dust generated from these activities).

Each activity was performed for 30 min, often in triplicate. The primary objective for testing BMMA-5353 was to quantitatively determine the airborne concentration of asbestos fibers, if any, in the breathing zone of workers.

Uses of this product typically did not include sawing or sanding, but it may have been drilled occasionally. For this reason, only small quantities were sawed, sanded, and drilled in this simulation study.

Personal (n = 40), area (n = 80), andbackground/clearance (n = 88) air samples were collected during each activity and analyzed for total fiber concentrations using phase contrast microscopy (PCM) and, for asbestos fiber counts, transmission electron microscopy (TEM).

The raw PCM-total fiber concentrations were adjusted based on TEM analyses that reported the fraction of asbestos fibers, to derive a PCM-asbestos concentration that would enable calculation of an 8-hour time-weighted average (TWA).

The estimated 8-hour TWAs ranged from 0.006 to 0.08 fibers per cubic centimeter using a variety of worker exposure scenarios.

Therefore, assuming an exposure scenario in which a worker uses power tools to cut and sand products molded from BMMA-5353 and similar products in the manner evaluated in this study, airborne asbestos concentrations should not exceed current or historical occupational exposure limits. - Mumford, John Kimberly. The Story of Bakelite. Robert L. Stillson Company, 1924.

- Rosato, D.V., ASBESTOS HISTORY & PROPERTIES [Book online] D.V. Roasato, engineering consultant, Newton MA, Reinhold Publishing Co., NY, 1959, Library of Congress Catalog No. 59-12535. We are in process of re-publishing this interesting text. Excerpts & adaptations are found in InspectApedia.com articles on asbestos history, production & visual identification in and on buildings

- Seabury, Ralph L., and Louis W. Murray. "Clutch throw-out bearing." U.S. Patent 2,035,988, issued March 31, 1936.

[Asbestos used in Bakelite component of clutch parts - Ed.]

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2018-11-20 2 - by (mod) - When was asbestos last incorporated into a phenolic board?

Keith

Because the longer I work on this topic the more I find that there are countless thousands of products that use asbestos, I suggest that you could assume that asbestos was used or may have been used in plastic material such as phenolic boards (circuit boards?) until after the asbestos banned in the country where you live.

That date varies widely by country.

Asbestos was certainly used in phenolic plastics as we discuss here

Also see asbestos in phenolic products cited in:

- Beckett, Thomas Allen. "Phenolic asbestos: an industrial hygiene analysis." PhD diss., California State University, Northridge, 1976.

Abstract: Air sampling was conducted at an industrial firm in Newport Beach, California, for six months during 1975. The membrane filter sampling and analysis method approved by the National Institute for Occupational Safety and Health (NIOSH) was utilized. Concentrations of asbestos fibers greater than 5 microns in length per cubic centimeter of air sampled, were mostly below 5 fibers per cubic centimeter.

Some concentrations, particularly those for sawing operations, greatly exceeded the 5 fibers per cubic centimeter value. Measured concentration levels for all operations were compared with employe medical histories to determine if health effects known to be associated with asbestos exposure were occurring. In many instances evidence of health changes such as reduced vital capacities and hilar calcifications were shown to exist among employes in the study group.

The membrane filter sampling and analysis method proved to be easy to learn and readily adaptable to most situations encountered in the field and laboratory. Most importantly, the sampling and analysis methods were highly reproducible once experience with the methods was gained. The data gathered indicate a need for the implementation of a comprehensive industrial hygiene sampling and control program, particularly for the sawing operations.

It is recommended that routine physical examinations and a training program be initiated for employes required to work with phenolic asbestos. Local exhaust ventilation controls for the sawing operations is necessary to reduce airborne asbestos dust concentrations below legally prescribed limits. - Hutcheroft, Clyde R. "Asbestos board." U.S. Patent 2,376,919, issued May 29, 1945.

- Schnabel, A. "Asbestos fiber extended phenolic adhesives." U.S. Patent 3,755,067, issued August 28, 1973.

- VULCANIZED RUBBER & ASBESTOS PRODUCTS - dog tags or identity discs to tires & hoses to modern gaskets & parts

On 2018-11-19 2 by Keith Chadwick

When was asbestos last incorporated into a phenolic board?

On 2018-09-02 - by (mod) - cones made of asbestos?

Clarifying: Rocket nose cones, aircraft or aircraft fuel tank nose cones.

On 2018-09-02 by Hitesh Jani

Applications of cones made of asbestos?

On 2017-06-21 - by (mod) - asbestos in trucks & other vehicles

Interesting question. I'll do some research.

In the meantime take a look at the firewall in the engine compartment and if you like use the page top or bottom contact link to send me photos of what you see

In ASBESTOS LIST of PRODUCTS you'll see listed uses of asbestos in tires, rubber products, and in insulating products.

Asbestos was and may remain in some talc or powder products used in the packing and handling of inntertubes used in car, truck, and bicycle tires.

See ASBESTOS in TALCUM POWDER

On 2017-06-21 by ayotteman@gmail.com

I have an early 1960's Peterbilt truck. Was wondering if there is any asbestos used in the cab for sound insulation etc?

On 2015-02-03 by J

Did semi truck inner tubes ever contain asbestos?

...

Continue reading at ASBESTOS PLASTIC COMPONENTS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ASBESTOS IDENTIFICATION IN BUILDINGS - home

- ASBESTOS HISTORY & PROPERTIES Rosato, 1959 Book Online

- ASBESTOS LIST of PRODUCTS

- ASBESTOS PHOTO GUIDE to MATERIALS

- ASBESTOS PRODUCTS BANNED vs PERMITTED U.S. 2023

- ASBESTOS PLASTIC COMPONENTS

- ASBESTOS PLASTIC ELECTRICAL PROPERTIES

- ASBESTOS PLASTIC MOLDING COMPOUNDS

- ASBESTOS PLASTIC PROPERTIES

- ASBESTOS in PLASTICS - p. 142-177 in Rosato

- ASBESTOS PRODUCING COMPANIES & TRUSTS

- ASBESTOS TESTING LAB LIST

- VULCANIZED RUBBER & ASBESTOS PRODUCTS

Suggested citation for this web page

ASBESTOS in PLASTICS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to ASBESTOS HAZARDS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

-

<

- [3] "Asbestos in Your Home," Spokane County Air Pollution Control Authority, Spokane WA 509-477-4727 www.scapa.org provides a one-page image, a .pdf file drawing of a house warning of some possible sources of asbestos in the home. The sources are not ranked according to actual risk of releasing hazardous levels of airborne asbestos fibers and the list is useful but incomplete.

- [7] Asbestos products and their history and use in various building materials such as asphalt and vinyl flooring includes discussion which draws on ASBESTOS, ITS INDUSTRIAL APPLICATIONS, ROSATO 1959, D.V. Rosato, engineering consultant, Newton, MA, Reinhold Publishing, 1959 Library of Congress Catalog Card No.: 59-12535 (out of print, text and images available at InspectAPedia.com).

- [8] "Handling Asbestos-Containing roofing material - an update", Carl Good, NRCA Associate Executive Director, Professional Roofing, February 1992, p. 38-43

- EPA, ASBESTOS IN YOUR HOME [PDF] - U.S. EPA, Exposure Evaluation Division, Office of Toxic Substances, Office of Pesticides and Toxic Substances, U.S. Environmental Protection Agency, Washington,D.C. 20460

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.