Heating System Pressure & Temperature Controls

Heating System Pressure & Temperature Controls

- POST a QUESTION or COMMENT about heating system operating pressures, temperatures, and controls for hot water and hot air heating systems and for warm air furnace systems

Hot water heating boiler pressure & temperature settings:

Here we explain where and how and to what numbers the pressure & temperature are set or controlled on hydronic heating boilers. We also describe where and how the pressure & temperature is controlled on residential steam boilers.

We include notes and links to detailed articles about the operation and use of controls on boilers, furnaces, and water heaters.

This article series answers most questions about all types of central heating system controls in order to aid in troubleshooting, inspection, diagnosis, and repairs.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

What Are the Normal Hot and Cold Operating Pressures of Residential Hydronic (hot water) Heating Boilers?

On a residential heating boiler the automatic water-feeder/pressure reducing valve that automatically provides makeup water to the heating boiler if pressure drops below 12 psi. So 12 psi is the typical "cold" pressure for residential boilers.

12 psi is for typical U.S. / Canadian residential heating systems normal cold temperature starting pressure. U.K. and european heating systems should be pressurized to between 1 and 1.5 bar - cold.

20 psi is typical for U.S. / Canadian residential heating systems normal hot operating temperature, up to just under 30 psi, depending on the high-limit temperature setting on the boiler limit control.

If we set the boiler high-limit much over 210, on many residential systems the system pressure will exceed 30 psi and we'll see water leaking from the pressure/temperature relief valve - ultimately an unsafe condition.

If your building is taller than two floors, the installer may have needed to boost the starting "cold" water pressure for your boiler to overcome the hot water distribution piping head pressure - otherwise your heating circulators may not be able to circulate hot water.

Causes of Variation in Pressure in Hydronic Heating Systems

Watch out: the actual pressure in a hydronic heating system is tricky to pin down. System pressure is only uniform throughout the system when the circulator pump(s) are off, there is no circulation by convection, and piping is entirely and only horizontal - not a realistic situation, right?

ITT Industries (B&G et als) point out in technical publications that the pressure you read on the pressure gauge is only the system pressure at that location and at that particular operating condition (temperature and circulator on or off).[1]

- The upper limit of water pressure

that should occur in a hydronic heating system is determined by the setting of the pressure relief valve (PRV). System pressures should not normally reach this upper limit. - The lower limit of water pressure

that should occur in a hydronic heating system is a little more complex to state but is nominally the cold-fill pressure, measured at the pressure/reducer - water/feeder valve.

The variables that determine the water pressure in the heating system include:

- The initial cold water pressure established when the system was filled

with water. Typical pressures (such as 12 psig) were discussed just above. Taller buildings will require higher pressures in order to actually circulate hot water (the circulator pump does not have sufficient lift capacity).

As a rule of thumb, 40 deg F. "cold" water (near standard density) gives us 0.43 psi per foot of altitude. (see above).

The pressure setting of the pressure/reducer water/feeder valve is set to maintain the system minimum "cold" pressure for proper operation. But notice that the location of the pressure/reducer - water/feed valve will affect the system pressure that it senses.

Located above or below the boiler, for example, causes the valve to see lower or higher pressures respectively on the boiler side of the valve. - The operating temperature of the heating system.

In a closed system the expansion of water as it is heated will increase the system pressure.

Water does not expand at a uniform rate in response to temperature rise; based on the ITT article we cited above we figure on about a 5% increase in operating pressure at normal heating temperatures.[1]

This is enough pressure to dump the PRV unless the system has an expansion tank (or "compression tank" in some literature) installed. Because the pipes containing heating water also expand slightly when hot ITT figures a net expansion of about 4.5% when the heating system is up to design temp. - The design, location, & condition of the expansion tank (compression tank).

The expansion tank must be properly sized (based on system volume, operating temperature range, relief valve setting, initial pressure, and relative heights of the expansion tank, relief valve, circulator pump, fill point (pressure/reducer water feed valve), and the highest point or "top" of the system.

Note that expansion tank manufacturers say the tank can be installed "anywhere on the system" - that's because of the operating range capacity of a properly-selected tank, not because the tank sees the same pressure everywhere it might be installed. - The circulating pump(s)

pressure differences caused when the pump is operating. Pump on or off changes pressures in the system. - Location of the boiler pressure gauge

in relation to the circulator pump's discharge point (and other piping and system components)

Definition of The Point of No Pressure Change - PNPC - where the Expansion Tank is Installed

The PNPC is the location in the heating system piping installation where the compression tank is connected to the system. Note that this is not really a point of "no pressure" since there is always some pressure in the system. It is a point of no pressure change [or pressure difference] on either side of the tank's inlet fitting.

Watch out: ITT notes that despite the instructions from manufacturers that an expansion tank can be installed anywhere, installing the tank on the discharge side of the circulator pump is a mistake.

The action of the pump [if the tank is installed on the discharge side of the circulator] now decreases the pressure below the non operating pressure of the system everywhere except in the small section between the pump and the tank.

In systems where the non operating pressure of the system is low compared to the pump head, the large reduction in pressure when the pump comes on could cause boiling in hot water systems, draw air in through automatic vents, or even result in pump cavitation. When the pump is located in this way, it also can cause a great deal of confusion. [1]

At PUMP, WATER PRESSURE BOOSTING we explain the relationship between building height and water pressure, and we illustrate the water pressure decrease in building water supply piping with building height. But a look at the basement water pressures in this illustration also explains the pressures that a basement located hot water heating circulator pump has to overcome.

Where & How do I Set Hot Water Boiler, Steam Boiler, or Furnace Temperature?

Hot Water Boiler Temperature Settings

Remember that the building THERMOSTATS set the desired temperature in the occupied spaces in building, not the actual temperature in the heating boiler or furnace itself. In most heating systems, turning up the thermostat simply causes the boiler or furnace to turn on.

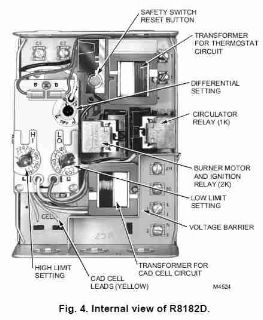

[Click to enlarge any image]The temperature at the boiler or furnace is controlled by local safety devices mounted right at that equipment, such as the heating boiler

AQUASTAT CONTROL shown here.

Hot water heating boiler normal pressure ranges as read on the pressure gauge, are described in this article, below.

The means by which a hot water heating boiler's pressure is set or controlled are described in this article below

at Where do I Set the Heating Boiler Operating Pressure?

For details how, to what number, and on what controls the hydronic heating boiler temperatures are set, also

see AQUASTAT CONTROL FUNCTIONS,

and LIMIT CONTROL, SINGLE.

Steam Boiler Temperature & Pressure Settings

Steam boiler temperature, pressure setting controls: For details how, to what number, and on what controls the steam boiler pressure settings and pressure readings are set see:

Warm Air Furnace Temperature Settings

Furnace temperature setting controls: Warm air furnace temperatures are controlled at

the FAN LIMIT SWITCH.

See FURNACES, HEATING for a complete discussion of warm air heat.

Additional furnace controls include register and duct dampers -

Hydronic (hot water) Heater Pressure Gauge and Normal Pressure Ranges

Pressure and Temperature gauge on hot water or hydronic heating boilers: this gauge displays the heating boiler internal pressure and temperature.

Typical pressure for a residential boiler serving a two story home would show 12 psi cold, and less than 30 psi hot. Over 30 psi boiler pressure will cause the pressure relief valve to open.

Typical operating temperature settings on a boiler call for a Low temperature (boiler cut-in) between 120 and 160 °F.

Typical operating temperatures on a hydronic boiler call for a high temperature (boiler cuts off) of 180-200 °F.

If we set the boiler upper temperature too high over 200 degrees F. we're at risk of spilling at the pressure temperature relief valve.

If we set the boiler upper limit too low, there may be no relief valve problem but under some conditions we may reduce the operating efficiency of the boiler and heating system, thus increasing heating costs.

See AQUASTAT CONTROL FUNCTIONS for details.

Typical operating temperature observed at the gauge will be below the high, and can be as low as nighttime room temperature in non-heating season if no tankless coil is in use.

The temperature/pressure gauge may help in checking for normal conditions before and during boiler operation.

However the gauge can be wrong!

This gauge shows a typical in-boiler pressure of under 20 psi, and a temperature of about 190 °F. (The boiler had just cut off on a heating cycle.)

For more diagnostic aid on finding the cause and executing the cure of abnormal heating boiler pressures see

- LEAKS at BASEBOARD, CONVECTOR, RADIATOR - how to find leaks at baseboards, radiators, etc.

- BOILER LEAKS CORROSION STAINS - how to diagnose & evaluate leaks on or in heating boilers

- BOILER LEAKS, HOW TO LOCATE - how to determine that a boiler or hot water system is leaking and how to find hidden leaks

- EXPANSION TANKS - if the expansion tank is waterlogged, the boiler and hot water heating system pressures will become excessive and spillage may be found at the pressure/temperature relief valve.

- PRESSURE / TEMPERATURE RELIEF VALVES On hot water heating systems (also referred to as hydronic heating systems) can also leak on their own - an unsafe condition.

For TP valves on steam boilers see STEAM HEATING SYSTEMS & Controls

Where do I Set the Heating Boiler Operating Pressure?

The operating pressure of a heating boiler (hot water or hydronic heat) is read at the pressure and temperature gauge (see above) and controlled by

- The starting or "cold water" pressure

at the boiler - typically at 12 psi is for typical U.S. / Canadian residential heating systems normal cold temperature starting pressure. U.K. and european heating systems should be pressurized to between 1 and 1.5 bar - cold.

Most heating boilers are provided cold makeup water through a pressure-reducing, back-flow preventing, automatic water feeder valve -

see WATER FEEDER VALVES, HYDRONIC BOILER. The valve is adjustable but should not be changed except by a trained heating service technician. - The ending or "hot water" temperature

at the boiler - typically 180 deg F to 210 deg F, controlled by the heating boiler's combination control, aquastat, or limit control -

see AQUASTAT CONTROL FUNCTIONS

and

see LIMIT CONTROL, SINGLE. - Heating equipment has multiple safety controls

designed to prevent damage to the equipment or unsafe conditions. Indirectly, or in emergency, the heating boiler pressure is limited by first, the high limit set on

- the AQUASTAT CONTROLS or LIMIT CONTROL, SINGLE

- Heating equipment relief valves:

If the temperature limit controls should fail, the boiler's temperature and pressure are released by one or more pressure/temperature relief valves:

- see RELIEF VALVES - TP VALVES On hot water systems

or RELIEF VALVE, TP VALVE, STEAM BOILER On steam heating systems. The operating temperature or pressure and relief capacity of these safety devices is matched to the BTUH input of the heating appliance. Pressure relief valves on residential and most commercial heating equipment are not adjustable.

The building THERMOSTATS do not normally directly control the temperature or pressure in the heating boiler. The thermostat sets the desired temperature in the building, but to the heating boiler it is working as a simple "on" - "off" switch, turning the boiler "on" until the thermostat is satisfied (the building is warm enough), then turning the boiler "off".

Residential Steam Boiler Normal Temperature Range

Temperature gauge on steam heating boilers:

Because a steam boiler makes heat by producing steam - by boiling water, at sea level, the temperature at the boiler will be boiling or 212 °F or close to that figure. Details are

Residential Steam Boilers Normal Operating Pressure

Residential steam heating systems are almost always designed to operate at very low pressures, perhaps around 0.2 to a maximum of 0.5 psi - that' s 1/2 of one psi. Click to enlarge and you can see the actual pressure settings on the steam boiler control shown at left. High rise building and some commercial steam heat systems operate at higher pressures.

Details are at STEAM BOILER PRESSURE - home.

If your residential steam boiler is operating at higher pressures that may be an indication that a service technician or owner was having trouble getting heat distributed through the building. Rather than finding and fixing the problem, someone is trying to "force" the steam around the system.

Also take a look at the dial setting on

your STEAM BOILER PRESSURE CONTROL SWITCH

Pressure Gauge Sources & Installation Guides

Moved to

WATER PRESSURE GAUGE INSTALLATION

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2021-02-11 by (mod) - no steam heat on the third floor of a house

@John,

The two most-likely causes are

- imroperly-sized, type, or clogged steam vents on radiators

- a blockage in condensate return from the third floor

Let us know what \your heating service tech says as that will help other readers.

On 2021-02-11 by John

I have a three story home, with a steam boiler system, and the heat doesn’t travel to the third floor. Why is that?

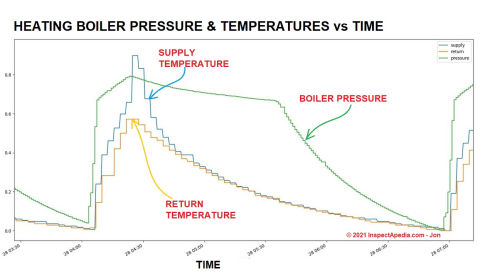

On 2020-11-28 by (mod) - charting boiler supply & return temperature vs. pressure over time

Jon

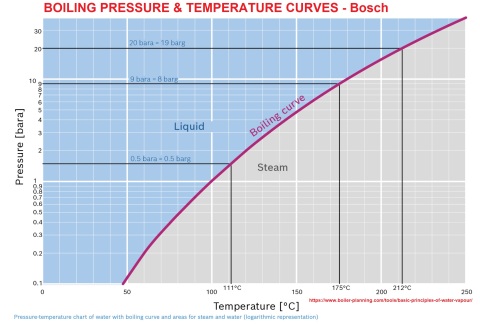

Nice instrumentation. An interesting graph. Thank you. I've annotated and edited your original chart slightly for clarity. The Bosch chart above is of course a smooth and logarithmic scale and represents theory rather than your "real world" actual measurement.

In general we would expect the boiler pressure to fall, as it does, mapping a decline in temperature in the boiler, affected slightly by the operation of the circulator pump.

I can't say if the failure of the pressure line to exactly map the shape of your temperature lines is an artifact of where you're measuring each of these or if there's an effect of thermal mass in the boiler.

Bosch has published a helpful article on this that I cite below, and from which the liquid, steam, and boiling curve vs. temperture (C°) shown above is excerpted. Bosch notes: "The diagram shows the pressure-temperature curves with the boiling curve. Please also observe the notices on reading logarithmic graphs."

Bosch, BASIC PRINCIPLES of WATER VAPOUR - retrieved anew 2021/04/20 original source: https://www.boiler-planning.com/tools/basic-principles-of-water-vapour/

I'd like to work further on your interesting question about the relationship between hydronic heating system pressure and temperature, for which some added details would be helpful:

- what is the left side scale ranging from 0.0 to 0.8?

- What would be the scales for pressure and for temperature respectively on your chart?

How and exactly where are you measuring pressure and temperature? What devices, at what locations in the system.

On a typical residential hydronic heating boiler the operating pressures in the system range from about 12 psi cold to just under 30 psi hot - principally thanks to the pressure increase associated with the thermal expansion of water as it's heated.

On a heating boiler,

Over 30 psi the temperature/pressure relief valve should open and spill hot water

Over 200F (more or less) the temperature / pressure relief valve should open and spill hot water.

There may be a slight difference in pressures in a hydronic system when the circulator is running, depending on where you measure water prressure, such as at the circulator pump outlet end vs. its inlet end, or at the boiler outlet vs. boiler return.

And there will be pressure variations across the building at various elevations or heights, again depending on how pressure is measured and exactly where.

Possibly of interest

THERMAL EXPANSION of HOT WATER

THERMAL EXPANSION of MATERIALS

Research on boiler pressure variation

- Taylor, Steven T., and Jeff Stein. BALANCING VARIABLE FLOW HYDRONIC SYSTEMS [PDDF] ASHRAE journal 44, no. 10 (2002): 17-20.

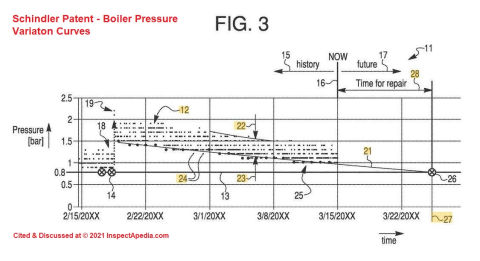

- Schindler, Zdenek, and Marek Sikora. EVALUATION OF HEATING LIQUID PRESSURE DROPS IN A HYDRONIC HEATING SYSTEM [PDF] U.S. Patent 10,401,039, issued September 3, 2019.

from which an example temperature/pressure chart is shown below.

- Boldt, Jeff, and Julia Keen. HYDRONCIS 101 ASHRAE Journal 57, no. 5 (2015): 62-70.

- Celorier Jr, George M., and Joseph Gerstmann. "Method and apparatus for increasing acceptance and adjusting the rate of pressure variations within a prespecified range in precharged fluid storage systems." U.S. Patent 5,778,679, issued July 14, 1998.

- Polchinski, Robert. "Avoiding System Problems When Using Expansion Tanks." ASHRAE Transactions 119, no. 1 (2013).

- Ryu, Seong-Ryong, Kyu-Nam Rhee, Myoung-Souk Yeo, and Kwang-Woo Kim. "Strategies for flow rate balancing in radiant floor heating systems." Building Research & Information 36, no. 6 (2008): 625-637.

- Strandberg, Roy, and Debendra K. Das. "Influence of temperature and properties variation on nanofluids in building heating." Energy Conversion and Management 51, no. 7 (2010): 1381-1390.

On 2020-11-28 by Jon

I have just added a pressure gauge in addition to supply and return pipe surface temperature gauges. Can you explain the strange relationship I see between pressure and heat in my system? The high is ~16psi for pressure and the high for supply/return is ~140F. About an hour after the boiler shuts off - the pressure decrease drops off in a somewhat non-linear fashion.

On 2020-09-28 - by (mod) -

Frank

Aquastat is a generic term for water temperature sensor control that includes controls used on water heaters and also on hydonic heating systems - i.e. boilers or forced hot water heat.

We discuss just about every aquastat type starting at

AQUASTAT CONTROLS

On 2020-09-28 by Frank

Is an aquastat just for domestic hot water? Of for forced hot water heat?

On 2020-09-28 - by (mod) -

Frank

Aquastat is a generic term for water temperature sensor control that includes controls used on water heaters and also on hydonic heating systems - i.e. boilers or forced hot water heat.

We discuss just about every aquastat type starting at

AQUASTAT CONTROLS

On 2020-09-28 by Frank

Is an aquastat just for domestic hot water? Of for forced hot water heat?

On 2018-11-29 by James

The cold water pressure of our boiler heating system is zero. But the hot water pressure is 50 PSI and hot water temperature is 220 F. We just changed a new PRV and Expansion Tank. But the problem persists.

Thanks for help

On 2018-10-15 - by (mod) -

Normal hot water heating system boiler oressure when cold is about 12 psi.

Call for repair

On 2018-10-14 by Sabina

Pressure gauge Is at 0 , what is it means?

IMAGE LOST by older version of Clark Van Oyen’s useful Comments code - now fixed. Please re-post the image if you can. Sorry. Mod.

On 2018-05-19 - by (mod) -

Mel

Watch out: a mistake can make the heating system unsafe to use.

A heating service tech would start by eliminating the thermostat from the situation by disconnecting its wires at the heating system primary controller.

If, after that step, jumping the two T T terminals together (that's what happens when the thermostat calls for heat) turns on the heater, then we know the problem is in the thermostat wiring between the thermostat and the heater, or the problem is with the thermostat and its connections.

On 2018-05-19 by Mel

Have changed old thermostat with new and still won't turn furnace on or off or regulate temperature leaving me to turn furnace on and off at furnace main wall switch what do I have to replace on furnace?

On 2018-01-17 - by (mod) -

Bill

The volume of water needed in a heating boiler depends on

- the type of heating boiler & system (steam vs. hot water)

- the physical dimensions of the boiler

- for hot water or hydronic heat, the total volume of all of the piping and radiators in the system

So there is not one "right answer"

A steam boiler is filled to a boiler water level line marked on or near the boiler sight glass

A hot water heating boiler is filled to eliminate ALL air from the system including boiler, pipes, radiators, baseboards.

On 2018-01-17 by Bill d

How much water does an empty. Boil we take or full do fill it back up and have another prob with water to faucet s is to hot

On 2017-12-03 - by (mod) -

Most heating boilers have an automatic water feed valve that will feed water into the boiler at 12 PSI when the system is cold. Your system has such a valve it's not working and you need your Plumber Heating service person to repair or replace it.

On 2017-12-02 by bt

I had a leak in the oil heating system and was fixed (pipe burst last Winter because cold temp.). We didn't use the oil heating system for about a year. Now there is no pressure (PSI) at all. The temperature reaches 180F-200F. I allowed water in the tank above the system by opening a valve to compensate for water lost when the pipe was leaking. Didn’t solve the problem. What can I do to fix the PSI issue? I was told it should reach between 15-20. Now it’s at zero. As a result, there is no heat in the house. Should I turn the oil heater on for a while, let us say 10 minutes or more?

On 2016-12-24 by Anonymous

I have barely any hot water pressure what do I do to get better pressure

...

Continue reading at PRESSURE & TEMPERATURE SETTING, CONTROL FAQs or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- AQUASTAT CONTROL FUNCTIONS

- EXPANSION TANKS, BOILERS

- GAUGES on HEATING EQUIPMENT

- PRESSURE GAUGE, BOILER

- PRESSURE GAUGE INSTALLATION GUIDES & SOURCES

- PRESSURE CONTROL, STEAM BOILERS

- RELIEF VALVES - TP VALVES

- RELIEF VALVE, TP VALVE, STEAM BOILER

- STEAM PRESSURE GAUGE

- WATER FEEDER VALVES, HYDRONIC BOILER

- WATER HEATER TEMPERATURE ADJUSTMENT CONTROLS - domestic hot water temperature

Suggested citation for this web page

PRESSURE & TEMPERATURE SETTINGS, CONTROLS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HEATING BOILERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about heating system operating pressures, temperatures, and controls for hot water and hot air heating systems and for warm air furnace systems

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- [1] "[Heating] System Pressure in Typical Hydronic Systems", TechTalk, Vol. 20, Issue 1, January 2005, ITT Industries, Fluid Handling [copy on file]

- [2] Domestic and Commercial Oil Burners, Charles H. Burkhardt, McGraw Hill Book Company, New York 3rd Ed 1969.

- [3] National Fuel Gas Code (Z223.1) $16.00 and National Fuel Gas Code Handbook (Z223.2) $47.00 American Gas Association (A.G.A.), 1515 Wilson Boulevard, Arlington, VA 22209 also available from National Fire Protection Association, Batterymarch Park, Quincy, MA 02269. Fundamentals of Gas Appliance Venting and Ventilation, 1985, American Gas Association Laboratories, Engineering Services Department. American Gas Association, 1515 Wilson Boulevard, Arlington, VA 22209. Catalog #XHO585. Reprinted 1989.

- [4] The Steam Book, 1984, Training and Education Department, Fluid Handling Division, ITT [probably out of print, possibly available from several home inspection supply companies] Fuel Oil and Oil Heat Magazine, October 1990, offers an update,

- [5] Principles of Steam Heating, $13.25 includes postage. Fuel oil & Oil Heat Magazine, 389 Passaic Ave., Fairfield, NJ 07004.

- [6] The Lost Art of Steam Heating, Dan Holohan, 516-579-3046 FAX

- [7] Principles of Steam Heating, Dan Holohan, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004 ($12.+1.25 postage/handling).

- [8] "Residential Steam Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- [9] "Residential Hydronic (circulating hot water) Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- [10] "Warm Air Heating Systems". Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- [12] Heating, Ventilating, and Air Conditioning Volume I, Heating Fundamentals,

- Boilers, Boiler Conversions, James E. Brumbaugh, ISBN 0-672-23389-4 (v. 1) Volume II, Oil, Gas, and Coal Burners, Controls, Ducts, Piping, Valves, James E. Brumbaugh, ISBN 0-672-23390-7 (v. 2) Volume III, Radiant Heating, Water Heaters, Ventilation, Air Conditioning, Heat Pumps, Air Cleaners, James E. Brumbaugh, ISBN 0-672-23383-5 (v. 3) or ISBN 0-672-23380-0 (set) Special Sales Director, Macmillan Publishing Co., 866 Third Ave., New York, NY 10022. Macmillan Publishing Co., NY

- [13] Installation Guide for Residential Hydronic Heating Systems

- [14] Installation Guide #200, The Hydronics Institute, 35 Russo Place, Berkeley Heights, NJ 07922

- [15] The ABC's of Retention Head Oil Burners, National Association of Oil Heat Service Managers, TM 115, National Old Timers' Association of the Energy Industry, PO Box 168, Mineola, NY 11501. (Excellent tips on spotting problems on oil-fired heating equipment. Booklet.)

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Fuel Oil & Oil Heating Magazine, 3621 Hill Rd., Parsippany, NJ 07054, 973-331-9545

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.