Steam Heat Condensate Piping, Pumps, Return LInes

Steam Heat Condensate Piping, Pumps, Return LInes

- POST a QUESTION or COMMENT about the causes & cures of trouble with steam condensate piping, pumps, reservoirs

Steam heating system condensate pumps & piping: this article describes and illustrates steam condensate return piping, condensate return pumps and steam condensate return reservoirs.

We also discuss leaks in steam condensate piping lines and chemical treatment of steam condensate.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Guide to Condensate Return Pumps & Condensate Systems on Residential Steam Heating Systems

Where condensate is unable to flow by gravity back to the steam boiler, a reservoir tank (under our client's hand at left) receives condensate from a low point in the building.

A float control and small pump moves condensate back to the steam boiler.

In the condensate receiver system shown in our photograph and on similar systems we have inspected in which the steam boiler is sometimes not even in the same building as the condensate receiving system, a control on the receiver sends water back to the boiler.

Condensate return pumps are also needed even when the steam boiler is in the same building, if condensate collection and piping are at locations too low to drain by gravity back to the steam boiler.

Watch out: where a separate condensate receiver is used, a feed pump to move condensate back to the boiler must be energized by a boiler-mounted condensate return pump controller. - Weil McLain 78

This steam system includes a plastic tank and injector pump used for chemical treatment of the steam condensate.

When the float in the condensate return tank activates the condensate return pump, that same circuit activates the small chemical injector pump mounted on top of the plastic reservoir at the right in our photograph.

See CHEMICAL TREATMENTS, BOILER

Article Contents

- CONDENSATE RETURN PIPES, PUMPS, STEAM - Condensate Return Pumps & Condensate Systems on Residential Steam Heating Systems - how to identify & troubleshoot steam condensate return piping

- CAUSES OF TROUBLE in the Steam Condensate System

- CONDENSATE RESERVOIRS & PUMPS problems with

- CORROSION On Steam Piping & Corrosion Control by Chemical Treatment of Condensate or Water

- LEAKS in steam condensate return piping

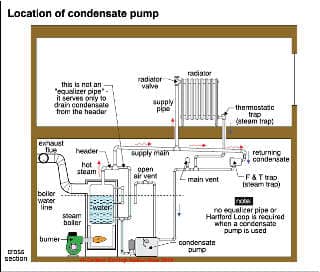

- LOCATION of the CONDENSATE RETURN PUM

Our photo above illustrates a steam condensate return pump system in a New York home.

[Click to enlarge any image]

Some Sources of Trouble in the Steam Condensate Return System

Watch out: problems such as blockages or leaks in steam condensate return systems can have various causes and can originate in many areas including at least these:

Watch out: problems such as blockages or leaks in steam condensate return systems can have various causes and can originate in many areas including at least these:

- Improperly sloped or routed condensate return piping can prevent condensate from returning to the boiler or can create blockages in piping that prevent steam heat from serving some radiators or building areas.

- A steam trap that is not working properly -

see STEAM TRAPS - A wiring error or electrical failure that causes the condensate pump to run backwards

- A system operating problem (such as bad steam vents) or other events (a leak) or conditions (water chemistry or poor maintenance) that causes too-frequent in-feed of water to the boiler, leading to corrosion and leaks in the condensate piping or in the boiler itself

- Improperly set or damaged boiler water feeder or water level controls

- Condensate reservoir leaks

- Condensate pump control switch problems: condensate level float switch inoperative, stuck, or having burned contacts

- Condensate pump motor troubles: motor not running, won't start, won't stop running, noisy

- See ELECTRIC MOTOR DIAGNOSTIC GUIDE for condensate pump motor problems

- Check for a dirty or clogged strainer blocking condensate flow in the reservoir or at the pump

- If the pump wont' stop running check for a leaky failed steam trap (s) or a valve that has been left partly closed or is debris-clogged in the condensate discharge line; also check for a broken or debris-clogged pump impeller

- Dirt or debris blockages at steam traps, or anywhere in the condensate return system piping, including at the Hartford Loop

Corrosion on Steam Piping & Corrosion Control by Chemical Treatment of Condensate or Water

Our second steam condensate return system (left) shows the reservoir and condensate pump motor (grey pump and new piping on the right side of the condensate reservoir at the left in that picture).

Steam condensate may be corrosive due to an improper pH level of the building water supply, or condensate water may be particularly corrosive to steam piping or to the boiler itself due to the formation of carbonic acid in the condensate liquid.

Carbonic acid itself forms because of the combination of high levels of carbon dioxide CO2 and oxygen in the steam piping system.

Steam piping that is made of copper is also vulnerable to a combination of ammonia and oxygen in the steam condensate.

Chemical treatment of steam condensate is typically done to reduce corrosion in the steam piping.

Other chemical treatments of water in steam boilers may be performed at the boiler itself to adjust the pH of the water or to control levels of corrosive carbonic acid using neutralizing amines or to control oxygen levels. [1]

A second approach to controlling steam system corrosion used particularly in steam systems that use a high volume of make-up water is the use of filming inhibitors or filming amines.

In a third approach to controlling steam system corrosion, water entering steam boilers may also be "de-aerated" by a feed water heater that removes excess oxygen mechanically.

Where do corrosion and leaks most often appear in steam piping?

Corrosion in steam piping is most likely to appear in the sections of steam condensate piping that remain filled with condensate. Those piping sections are found near the steam boiler itself or at steam condensate return reservoirs and pumps.

To control or reduce the corrosion and leaks caused by corrosive steam condensate the steam boiler water may be pre-treated or the condensate may itself be treated as we illustrate in our photo above.

See CHEMICAL TREATMENTS, BOILER for details about additives to control scaling, surging, corrosion, etc. in boilers

Above: a condensate return pump for a steam heat system is needed when condensate cannot easily flow back to the steam boiler by gravity alone.

Illustration courtesy of courtesy of Carson Dunlop Associates a Toronto home inspection, report writing, and education company. [Click to enlarge any image]

Below: a remote condensate return pump is used in this Poughkeepsie NY home to get condensate from a low condensate drain system back to a boiler located slightly higher in the same basement.

Corrosivity of Steam Boiler Condensate: Research

- [1] Boiler Systems, Chemical Treatment, Association of Water Technologies, Technical Manual, web search 04/22/2011, original source: http://www.steamforum.com/pictures/water%20treat%20Boilers%281%29.pdf

- [2] "Steam/Condensate Treatment, An Overview of Monitoring and Treatment", John J. Baum, Craft Products Co., Inc., White Paper prepared for P.C.I. Controls and Instrumentation, Seminar, August 1995, web search 04/23/2011, original source: http://www.craftprod.com/research/Steam%20-%20Condensate%20Treatment.pdf

- Weil McLain Model 78 Boiler Manual, Boiler for gas, light oil, Gas/Light Oil fired Burners, Installation, Start-up, Parts, Maintenance instructions, Part No. 550-141-705/0600, Weil-McLain Administrative Office, 999 McClintock Drive, Suite 200, Burr Ridge, IL 60527

Tel: 855-248-1777

Consumer Inquiries: 800-368-2492

Technical Services: 800-526-6636 Technical Support for Contractors Only.

If you are a homeowner and are experiencing a problem with your Weil-McLain equipment, the first step you must take is to contact your installer or locate an HVAC contractor in your area. Website: http://www.weil-mclain.com - "The Fight Against Corrosion - A Study of the Nature of Corrosion and its Problems in Water Services and Heating Systems", Daniel Davies, Research and Development Services, Stansted Mountfichet, Essex, England, World Plumbing Conference-IV, "Plumbing and the World Environment, Compendium of Workshop Papers, October 3-6, 1996, Hyatt Regency Chicago, Chicago, IL", [personal correspondence, DJF - Author, July 2011]

Leaks in Steam Condensate Return Piping

Our photograph at left shows a leaky steam condensate return line close to the steam boiler.

This steam condensate line leak has been dripping for more than a decade. Unlike a hydronic heating boiler system, because the pressure in the steam condensate return line is low, the leak was not noticed by the homeowner and it was ignored by the heating service technician.

While not all of the piping is clearly visible in this image, you are also looking at part of

a HARTFORD LOOP.

Because steam condensate may be quite corrosive in steam heating systems commercial systems and some residential steam heat systems use additives or water conditioners to minimize those effects.

Without the Hartford Loop properly sized and piped at the condensate return to the boiler, complete loss of boiler water could follow a leak in the condensate line.

In turn, loss of boiler water can destroy the boiler or can lead to catastrophic

BLEVE EXPLOSIONS

Our opinion was that the piping in this steam condensate line section all should be replaced, but it was reasonable to wait until the end of the heating season rather than having to shut down the heater during freezing-cold weather.

Watch out: never pick at corrosion on a heating pipe: we warned the homeowner not to poke or pick at the corrosion on this piping. Disturbing the condensate return pipe was likely to result in a sudden and much larger leak that could leak badly, resulting in basement water problems and increased steam boiler water consumption.

Watch out: a leak in the condensate piping of a steam heating system can lead to very expensive damage including:

- Leaks into the building causing rot, inviting insect damage, or leading to a costly mold cleanup job

- Excessive water in-feed to the boiler, leading to increased rate of corrosion in the condensate piping or even the boiler itself, risking the development of additional leaks that can destroy the boiler

More details about steam condensate return pumps for residential properties are in process, photo contributions needed. CONTACT us.

Steam Condensate Return Pump Location

The steam condensate reservoir and pump system shown here has had that to which we all aspire: a long and interesting life. The Poughkeepsie NY home where this condensate return system is installed was originally heated by an extensive underground steam pipe network hosted on the Vassar College campus.

The steam condensate reservoir and pump system shown here has had that to which we all aspire: a long and interesting life. The Poughkeepsie NY home where this condensate return system is installed was originally heated by an extensive underground steam pipe network hosted on the Vassar College campus.

This was a faculty-housing home that for many decades supported a program of encouraging Vassar faculty to live on or near the campus, both as a benefit to campus life for students and as an attractant to faculty.

Heat to the home was provided by the college by extending a nearby steam pipe network that was already using steam to heat campus buildings.

OPINION: however when a home owner or occupant does not pay directly for their own heat we often find significant heat waste and little concern for energy conservation.

I suspect that Vassar College found the same because ultimately the home and others like it was disconnected from the original steam piping loop and was given its own in-home steam heating boiler.

When the building was disconnected from the original steam piping loop and a new steam boiler installed, the lowest level of condensate return pipes was located such that steam condensate in this home would not return by gravity to the steam boiler.

So the condensate pump had a second life, continuing in service to return condensate not to Vassar's steam system but locally, to the in-home steam boiler, by piping returning condensate up, across the basement, and down to the new steam boiler.

The small gray box attached to the larger light gray condensate reservoir is a controller that turns the condensate return pump on when the condensate level rises in the reservoir.

The blue condensate pump motor can be seen to the right of the gray condensate reservoir.

The condensate return pump data tag is so old as to be a bit difficult to read but if you click to enlarge it you will see that this is an ITT Hoffman Pump product sold under the Watchman condensate return pump and steam condensate reservoir brand.

The original pump was rated for 115V 50HZ and bore serial # 160002.

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-10-12 by Patricia - old Vassar Faculty houses on Raymond and are having issues with the ITT Hoffman Pump.

We are currently living in one of the old Vassar Faculty houses on Raymond and are having issues with the the exact same condensate return pump ITT Hoffman Pump.

We are currently living in one of the old Vassar Faculty houses on Raymond and are having issues with the the exact same condensate return pump ITT Hoffman Pump.

We just had the boiler serviced today and it's fine but when we turned up the heat during the service the pump had water leaking onto the floor and it's unbearably loud.

Please help us try to figure out how to fix it and keep it from leaking before the colder months arrive. pa3cialuciopenn@gmail.com Thank you!

We purchased and currently live in a Vassar College Faculty Home and have the exact same box and condensate pump discussed and as the one pictured on your site.

We have only been in this home for a year and a half and have had our kids move back due to COVID and compromised immune systems. We also are trying to get my mother in law back home from a nursing home to live with us. It's a large old home with a gas heating steam system.

We just had our Boiler serviced and cleaned today 10/12/20 and the worker accidentally turned on the pump but when we turned on the heat for the testing the pump was spilling water and leaking. When we found the leaking I turned on the pump on and it seemed to work but is very loud! were worried this will happen again when we put the heat on or up.

Please help us resolve what needs to be done to fix and or replace the pump before the winter month and to make it safe. Any help would be appreciated! I made a comment and attached a picture but I'm not sure if you have reviewed for posting.

The small gray box attached to the larger light gray condensate reservoir is a controller that turns the condensate return pump on when the condensate level rises in the reservoir.

Steam condensate return pump (C) Daniel Friedman at InspectApedia.com

The blue condensate pump motor can be seen to the right of the gray condensate reservoir.

The condensate return pump data tag is so old as to be a bit difficult to read but if you click to enlarge it you will see that this is an ITT Hoffman Pump product sold under the Watchman condensate return pump and steam condensate reservoir brand.

The original pump was rated for 115V 50HZ and bore serial # 160002. - Anonymous by original post at InspectApedia.com and also by private email.

On 2020-10-13 by (mod)

I am familiar with those Vassar College house steam heating systems, Patricia.

Vassar's central steam boiler used to heat the houses along Raymond, (and beyond) so those homes each had a big condensate pump that returned condensate back to the central system, but over time the college has been eliminating those by installing a new independent boiler in each home, eliminating the connection to the main campus steam loop.

However because the original steam piping in those houses sometimes looped too low to drain back to the new boiler by gravity the system still used the condensate return pump to lift the condensate back to the boiler's return inlet.

So your system may still need that pump.

Take a close look to see exactly where the leak is occurring.

If it's at the condensate return system, is it leaking out of the reservoir or out of a pipe connection or, as I fear, out of the pump itself - as your message suggests.

If the leak is at the pump then probably a pump shaft seal is gone and the pump needs to be repaired or replaced.

Does Vassar's B&G service your boiler or are you responsible for that?

Reader follow-up:

Thank you for your response. We are responsible for the repairs needed.

Last night we turned off the condensate pump and left the heat set to 69. This morning the white bucket was full and there was more water on the ground.

We turned off the heat for now and the pump.

We called McCourt Heating and cooling to follow up but do you recommend anyone else?

Moderator reply:

I've so long been retired from the heating service world that I can't offer a specific referral, but if the company has a tech who's experienced with steam systems you should be ok.

If the person doesn't know about condensate pumps call the service manager and ask for more help.

I suspect the pump has failed; At another Vassar house I found a whole pile of dead condensate return pumps off in a corner - that made me wonder who had been doing that repair work. A misaligned pump can also cause bearing failure.

You were right to turn off the heat - before your boiler's safety control (low water cutoff) did it for you.

There is also regular homeowner maintenance needed for steam systems - flushing out that LWCO - probably weekly - depending on how much water your system uses.

If you're not familiar with what you need to do ask the service tech to go over it with you.

Reader follow-up:

We have the heat and the pump off at the moment.

I've attached pictures and the QUOTE for CONDENSATE SYSTEM REPLACEMENT [PDF] for the repairs from McCourt. [Personal data removed - Ed.]

Does that amount seem reasonable for the repairs and work? We were given another company from Vassar College that might be able to give us another quote.

Moderator reply:

I cannot be as smart as the on-site people

I do note that they propose to replace the entire condensate receiver system - that's why the price is what it is and if that's what's needed the price is probably reasonable if there's much labor and struggling with nasty corroded piping.

A new Hoffman condensate receiver system - just the parts - cost about half of what they're bidding.

A question to ask when you have someone on site again is: can you replace just the bad pump ?

If they say they need to replace the whole assembly, politely ask to be educated a bit as to how we decide that. It might indeed be the case - or maybe not.

Certainly the system is designed such that if the reservoir and other parts are intact the pump alone can be replaced.

So the answer is ... it depends.

On 2020-08-21 by steve

i have a steam gas boiler,green mountain

does the return line have to run around basement or can it start to pitch upward directly from boiler??

On 2018-05-28 by (mod)

I don't think you would see plastic used for steam system piping

On 2018-05-28 by Anonymous

what type of pipe do you use to repair pipe? Can PVC be used?

On 2016-11-18 by Dave

I have a leak under my radiator i cut out the ceiling and the is a little leak were the pipe is can i solder it closed

On 2016-01-13 by Victoria

I have a VERY badly corroded return pipe, this article states that copper is susceptible to corrosion as well so what type of piping should be used? Also another question about gas line into boiler.. I am in a two family house, meters, and appliances completely separate. So why would my gas have to be "on" running into my boiler for my neighbors to work?

...

Continue reading at HARTFORD LOOP or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CHECK VALVES, HEATING SYSTEM

- CONDENSATE RETURN PIPES, PUMPS, STEAM

- HARTFORD LOOP

- LOW WATER CUTOFF VALVE

- SIGHT GLASS, STEAM BOILER

- STEAM HEATING SYSTEMS & CONTROLS - home

- STEAM TRAPS

- STEAM VENTS - home

- WATER FEEDER VALVE, STEAM

Suggested citation for this web page

CONDENSATE RETURN PIPES, PUMPS, STEAM at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem

INDEX to RELATED ARTICLES: ARTICLE INDEX to STEAM BOILERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Questions & answers or comments about the causes & cures of trouble with steam condensate piping, pumps, reservoirs.

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- The Steam Book, 1984, Training and Education Department, Fluid Handling Division, ITT [probably out of print, possibly available from several home inspection supply companies] Fuel Oil and Oil Heat Magazine, October 1990, offers an update, (see next item in this list). ITT Fluid Technology,

1133 Westchester Avenue

White Plains, NY 10604, tel +1 914 304 1700 fax +1 914 696 2950 www.ittfluidbusiness.com - Principles of Steam Heating, $13.25 includes postage. Fuel oil & Oil Heat Magazine, 389 Passaic Ave., Fairfield, NJ 07004.

- The Lost Art of Steam Heating, Dan Holohan, 516-579-3046 FAX

- Principles of Steam Heating, Dan Holohan, technical editor of Fuel Oil and Oil Heat magazine, 389 Passaic Ave., Fairfield, NJ 07004 ($12.+1.25 postage/handling).

- "Residential Steam Heating Systems", Instructional Technologies Institute, Inc., 145 "D" Grassy Plain St., Bethel, CT 06801 800/227-1663 [home inspection training material] 1987

- The Heat Efficiency of Steam Boilers, Bryan Donkin

- Steam Boiler Operation, Principles & Practice, James J. Jackson

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.