Thermocouple Sensor Replacement

Thermocouple Sensor Replacement

Thermocouple types, selection, replacement instructions

- POST a QUESTION or COMMENT about thermocouples used on heating equipment & water heaters to monitor gas pilot lights

Thermocouples on heating appliances: this article describes thermocouples, safety devices used on gas fired heating equipment. The thermocouple or thermopile monitors the presence of a gas flame, such as at a gas appliance pilot light.

Here we describe how to find the thermocouple if one is used on your heater, and how to replace a gas pilot thermocouple sensor.

We also explain the difference between a thermocouple and a thermopile.

This article series explains what a thermocouple (or thermopile) is, how these similar devices work to support a pilot light on a gas burner, where they are installed, and what goes wrong with thermocouples.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Thermocouples: Definition & Uses in Gas Fired Heating Equipment

What is a Thermocouple & Where are They Used on Heating Equipment?

What is a Thermocouple & Where are They Used on Heating Equipment?

A thermocouple is an electrical device that responds to temperature change by a change in voltage output.

A thermocouple works to produce a small electrical voltage output by connecting two dissimilar metals or two wires forming a measurement junction at the sensor tip of the device.

When heated the effect of the two dissimilar metals in contact with one another is the production of an electrical current.

This voltage in turn can be used to cause a gas valve to open or remain open, or to close, stopping the supply of LP or natural gas fuel should a pilot light or gas flame go out on a heating appliance.

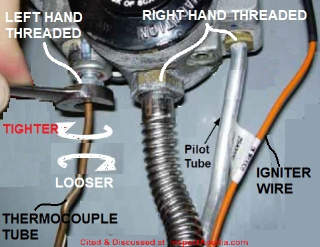

In our photo above you can readily determine that this is a thermocouple by noticing that its connection the the gas valve is a flexible copper tube.

Article Contents

- THERMOCOUPLE SAFETY

- THERMOCOUPLE LOCATION - where is it?

- THERMOPILE vs THERMOCOUPLE - what's the difference?

- THERMOCOUPLE INSTALLATION or REPLACEMENT - how to choose and install a new thermocouple

- NO PILOT: DIRECT IGNITION GAS SYSTEMS - there is no pilot light - some appliances use an igniter instead

- THERMOCOUPLE TYPES

- THERMOCOUPLE IO MANUALS

This page describes how to choose and install a replacement thermocouple.

If you need to diagnose why your gas appliance pilot light won't stay lit (and fix it), see

- GAS PILOT WON'T STAY LIT - pilot light used to work but now keeps going out or won't stay lit - separate article

- GAS PILOT THERMOCOUPLE INSTALLATION SNAFUS - pilot light has never worked well - separate article

The Thermocouple is a Safety Device

Watch out: The thermocouple isn't there just to "ignite the gas flame". It's there to prevent the main gas valve from opening if the gas flame won't ignite.

Shutting down the gas supply to a heating appliance protects against a gas fire or explosion that could occur if a gas regulator valve remain open without proper ignition of the gas flame.

A thermocouple can also serve as a process controller or in other applications outlined

In general we think that thermocouples are less accurate and less sensitive temperature sensors than thermistors, but these low-cost and reliable temperature sensing devices have been used successfully in heating equipment such as gas fired furnaces, boilers, and water heaters for decades. Thermocouples are also used on gas logs and in gas fireplaces or similar devices.

Thermocouples are produced in a wide range of forms and configurations, in eight or more calibration groups (B,E, J, K, R, S & T) with different temperature ranges including up to very high temperatures such as 3000 oF.

Don't confuse a thermocouple (discussed here) with a different type of temperature sensor, solid-state

THERMISTORS used in thermostats.

Where are Thermocouples Used on Heating Equipment?

Thermocouples are used as safety devices that will shut off equipment by shutting down the LP or natural gas fuel supply on some gas-fired heating equipment such as gas fired furnaces, gas fired heating boilers, and gas fired water heaters.

Thermocouples are used as safety devices that will shut off equipment by shutting down the LP or natural gas fuel supply on some gas-fired heating equipment such as gas fired furnaces, gas fired heating boilers, and gas fired water heaters.

Typically the thermocouple sensor is mounted right in the flame of the pilot light on gas fired heating equipment.

Our photo (left) shows how you may spot the copper tubing of the thermocouple extending between its sensor at the pilot flame of a gas burning furnace and its connection to the gas control valve.

[Click to enlarge any image]

The thermocouple on gas fired heating appliances is mounted to sense the presence of a gas flame or gas pilot flame. The other end of the thermocouple's tubing connects to a port on the gas regulator or gas valve

But not all of these systems use a thermocouple. Some gas fired heating equipment relies on an electronic ignition to ignite the flame. Those devices generally will not use a thermocouple.

If a thermocouple is used you'll see a small copper tube (or in some devices an electrical wire) connecting the flame sensor to the valve.

The thermocouple and safety shutoff do double duty, since on burners that use a pilot flame the thermocouple senses the pilot flame and won't permit the

gas valve to open if the pilot is not lit.

A bad thermocouple itself can prevent a gas furnace or boiler from working - if you can light the flame at the pilot manually but then the flame goes out when you release the manual gas feed valve, the thermocouple is probably bad.

What's the Difference Between a Thermopile and a Thermocouple?

A thermopile looks a lot like a thermocouple, and does a similar job - sensing temperature, such as a gas flame to function as a safety device.

A thermopile looks a lot like a thermocouple, and does a similar job - sensing temperature, such as a gas flame to function as a safety device.

Our sketch above, illustrating a typical use of a thermopile, a type of thermocouple, in use at a gas boiler, is adapted from Weil McLain.[3]

On both thermocouples and thermopiles used to maintain a gas pilot at any gas appliance that uses a standing pilot (always on), the thermocouple sensor tip or thermopile sensor tip must be immersed in the gas burner pilot flame as shown in our drawing.

Watch out: thermopiles and thermocouples are not interchangeable. When replacing a temperature sensing device like a thermocouple or thermopile, you should be sure to purchase the proper part.

Thermopiles are made by combining multiple thermocouples together in series in order to produce more electrical current than a basic thermocouple. Externally a thermopile still looks like a single sensing device.

Thermopiles are used to measure temperature without having to contact the object being measured.

- A thermocouple

relies on direct contact between its sensor tip and the object whose temperature is being measured.

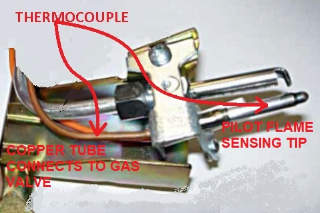

A thermocouple always includes a flexible copper tube that connects the thermocouple to the gas valve. - A thermopile

relies on its ability to absorb infrared radiation (IR) emitted from the surface of the object being measured. No direct contact is needed. The sensor surface of a thermopile is usually coated with a "black body" surface to improve its IR absorption. - (Thermometrics Corporation 2017)

A thermopile controls the gas valve by an electrical signal: there will be two wires connecting the thermopile to the gas valve and there will NOT be a flexible copper tube.

At THERMISTORS we explain the differences among a thermocouple, thermopile and thermistor in more detail. There we note that millivolt thermopiles are used in lieu of a simpler thermocouple when the device needs to operate a thermostat as well as the gas valve.

Thermocouple Selection & Installation

Watch Out: Proper selection and installation of a thermocouple is important for the device to function safely, or for that matter to function at all.

Watch Out: Proper selection and installation of a thermocouple is important for the device to function safely, or for that matter to function at all.

The manufacturer of the heating appliance in which the thermocouple is used will provide installation instructions that must be followed for safe, reliable use of the heating appliance.

Follow the instructions in the manual or guide for your heating appliance and also review the installation instructions and bending instructions that came with a replacement thermocouple.

The connecting copper tubing length for a thermocouple is not usually critical, but the tubing must be long enough to reach without stress from the connection at the gas valve to the thermocouple's sensor mount in the gas flame or pilot flame.

The thermocouple is provided with the connecting tubing coiled neatly in a package. Don't be afraid to uncoil the tubing into a more straight line to ease installation of the device. But do not nick, kink, nor make sharp bends in the tubing.

Typical thermocouple installations include instructions for bending the tubing to avoid sharp bends or nicks.

Watch out: don't modify a thermocouple (other than gentle bending as described in the installation instructions). For example do not try to cut or trim the length of the thermocouple.

Doing so will almost certainly make it inoperative and thus unsafe. If your gas fired equipment also uses an igniter wire in addition to the thermocouple, they are often routed together and will need to be removed for thermocouple replacement. Take care not to damage the igniter wire and to reconnect it just as it was.

Typical Thermocouple Installation Steps

Installation steps for installing a replacement thermocouple are simple, and are made easier by looking carefully at how and where the old thermocouple was installed and where and how its tubing was routed between the gas valve and the flame sensor position. You can make your job easier by shutting off the gas supply and removing the old thermocouple intact to help select a replacement model.

Replacement thermocouples using "universal mounting" include clips and fittings that will work on most gas fired heaters and water heaters.

For example Sid Harvey's Dyna-Couple universal mounting thermocouple, sold in lengths from 18" to 48" will replace Honeywell, Robertshaw, Penn Baso, White-Rodgers and other thermocouples.

- Turn off the gas supply to the equipment.

Locate the gas supply control valve, or on a water heater, the combination gas control valve and thermostat and turn gas off there.

On a gas line valve the "off" position is with the handle at right angles to the gas pipe.

On a gas fired water heater the gas control valve handle will have an OFF position that is aligned with a mark on the body of the gas valve. - Remove access covers as needed:

on a gas fired water heater you will need to remove the manifold door at the heater bottom in order to access the end of the thermocouple that mounts on and monitors the pilot flame.

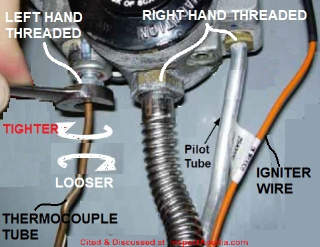

On a gas-fired furnace you may need to remove first the furnace cover and then a flame shield. Keep any mounting screws for re-use. - Remove the old thermocouple at the gas valve

by unscrewing its mounting bolt from the gas valve. Typically a thermocouple connects to the bottom of a gas valve using "right-hand" threads.

Watch out: DO NOT FORCE any fittings or you may break something.

You should find that you turn the screw clockwise to loosen a right-hand-threaded connector. The wrench size is typically 7/16". Pull down gently to pull the thermocouple's end out of the mounting well on the gas valve. - Remove the other end of old thermocouple sensor at its mount at the burner or pilot flame.

Typically there is a clip that holds the thermocouple to the pilot flame tube.

Before taking this clip off, take note of where the clip was located on the larger-diameter segment of the copper thermocouple tubing, as you'll want to clip the replacement unit in the same location.

Keep all of the old sensor mounting parts. On occasion you may need one or more of these to properly secure the new thermocouple sensor in place. - Prepare & bend the new thermocouple tubing:

gently unroll the new thermocouple tubing.

To make necessary bends to route the thermocouple into position between the pilot-sensing end and its screw-in connection to the gas valve, use the bending template in the installation instructions.

If you don't have bending instructions, use a round object 2-3" in diameter and keep bends gentle, avoiding crimping or squashing the tubing. - Route the replacement thermocouple

into place in the same location and using the same routing as the old one that you removed.

Watch Out: if you do not route the thermocouple just as the original it may not operate properly.

But extra length should not be a problem if you coil the extra length (or never uncoiled it) and leave it near the point of connection to the gas valve. - Mount the sensor end of the thermocouple at the pilot / flame

into its supporting bracket next to the pilot flame tubing.

A small nut or clip is used on many appliances to hold the sensor tip in proper position. - Reinstall covers:

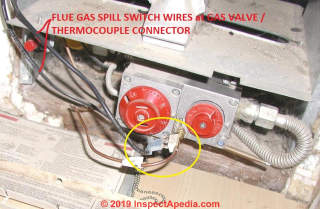

a flame shield or manifold door that you removed from the heater or water heater. - Reconnect the end of the thermocouple to the gas control valve

where the old thermocouple end was unscrewed.

You should find that you turn the screw counter-clockwise to tighten a right-hand-threaded connector.

Tighten the new thermocouple first by hand, gently, taking care not to cross-thread the connecting nut. When the connector is turned fully tight by hand, use the 7/16" wrench to make a final quarter turn.

Watch out: do not over-tighten the connector at the gas valve. But don't under-tighten either

: be sure the connector has been screwed all the way in. Otherwise the thermocouple may not properly report the presence of pilot flame and the gas valve will not open.

Watch out: Do not cross-thread the thermocouple's connector at the gas valve.

Do not apply thread sealant to the connector. Either of these mistakes may result in failure to detect a pilot flame and the gas valve may not open when it should, either intermittently or as a hard failure. Both parts may need replacement.

Watch out: failure to place the tip of the thermocouple in proper position

to sense the gas pilot flame is a common source of heater troubles and failure to operate.

Watch out: failure to properly seat the thermopile or sensor end of the thermocouple at the gas valve

(the end opposite of the flame-tip) into its recess in the gas control can also prevent proper gas heater operation:

you may have trouble lighting the gas flame or keeping it lit, and symptoms will be the same as if the thermocouple assembly were defective. In the photo below my wrench and the round white arrow show the connection to which I'm referring.

If you keep the thermocouple tubing straight for at least an inch at this connecting end there's a better chance that it will seat properly in the gas control.

Note that in the photo below I am loosening the connector.

Turn the screw clockwise to loosen a right-hand-threaded connector such as this one, and turn the screw counter-clockwise (opposite direction as that white arrow) to tighten the connector.

Watch out: some gas thermocouples are left-hand threaded - reverse of standard. You can't connect a left-hand threaded thermocouple to a right-hand threaded gas valve. - Turn on the gas and check for leaks.

Watch out: Test for gas leaks? If any gas connections were removed and replaced (usually not necessary if you are only replacing a thermocouple) then check for leaks using a chloride-free soap and water solution.

You should not see any bubbles. If you see leaks turn the gas supply back off immediately. Any leaks must be fixed immediately. More help is at

GAS LP & NATURAL GAS SAFETY HAZARDS

Watch out: Do not turn on nor try to use gas fired equipment if there is a gas leak. Doing so risks fire, explosion, injury, even death.

Our white arrow shows turning the thermocouple copper tubing connector at the gas valve clockwise to loosen it.

Watch out: thermocouples usually use a left-hand thread to attach the sensor to the gas valve.

To loosen this left-hand threaded thermocouple connector you'll use a 7/16" box wrench and turn the fitting CLOCKWISE or to the right to LOOSEN it - opposite of the more-common right-hand threaded fittings.

Gas fittings are usually tapped with a left-handed thread as a safety feature to prevent confusing gas piping with water lines.

For left-hand threaded fittings, turn to the right (clockwise) to loosen and to the left (counter-clockwise) to tighten left-hand threaded fittings.

The other two larger fittings for the gas manifold tube (center) and the pilot tube that conducts gas to the pilot light are right-hand thread. To loosen those you'd turn the fittings in the usual direction:

For normal right-hand threaded fittings, "leftie-loosie" and "rightie-tightie" tell us which way to turn the fitting to loosen or tighten it.

Photo adapted from American Water Heater Thermocouple installation instructions given in detail at the end of this page at our "click to show/hide"References or Citations section.

What if there is NO Constant-On Pilot Light? Direct-Ignition Gas Fired Heaters

Many modern gas fired heating appliances, boilers, furnaces, water heaters, use an electronic ignition or spark to light the pilot.

On these appliances there may still be a thermocouple to confirm that there is a good gas flame when the burner is on - since we don't want to continue supplying gas if there is no flame (doing so risks an explosion).

If your appliance has a flexible electrical wire that connects to a sparking device at the burner or burner pilot, the appliance has no continuously-on pilot - you do not have to light the pilot manually.

In our photo at far left the yellow and blue wires is the safety sensors & direct ignition wiring connected to an igniter that will be found at the pilot light.

In addition to finding electrical wires leading to an igniter at the gas burner or gas pilot, you will also see a tag such as that shown on this gas valve on an A.O. Smith gas fired Direct Ignition water heater (photo at close left).

Types of Thermocouples

The thermocouples used in building mechanical systems are generally type K: thermocouples used in heating boilers, calorifiers, geysers, gas burner applications (flame sensors). Type K thermocouples are widely used in industrial applications involving water, mild chemical solutions, hospitals and the food industry.

Here, courtesy of Pyrosales, an Australian provider of thermocouple devices, is a complete list of the types of thermocouples and their applications.

Thermocouple Types & Applications |

|||

| Thermocouple type | Applications | Temperature Range | Comments |

| Type B thermocouple | Metal industries: steel, iron | ||

| Type C thermocouple | Very high temperatures, space vehicles, nuclear reactors, industrial heating, research, vacuum furnaces | ||

| Type E thermocouple | Very cold temperatures, sub-zero, oxidizing or inert (non-corrosive) environments, cyrogenic, pharmaceutical, chemical | 95-900°C 200-1650°F |

|

| Type J thermocouple | Vacuum, inert, reducing atmospheres, hot processes, eg: plastic & resin mfg. | 95-760°C 200-1400°F |

|

| Type K thermocouple | Building mechanical systems, oil & gas heating, water heaters, gas burner flame safety, water, mild chemicals, gases, dry areas, engines, hospitals & food industry. Type K (chromel-alumel) are the most-widely-used general purpose thermocouple | −200 °C to +1350 °C −330 °F to +2460 °F |

INSTALLING A K-TYPE THERMOCOUPLE [PDF] |

| Type N thermocouple | Vacuum & controlled atmospheres, high temperature kilns, ovens, furnaces, gas turbine engine exhaust monitor, metal industries: aluminum & smelting | 95-1260 °C 200-2300 °F |

|

| Type R thermocouples | Heat treatment, process control, semi-conductor, glass industries, metal industries: ferrous & non-ferrous | 870-1450 °C 1600-2640 °F |

|

| Type S thermocouples | Heat treatment, process control, semi-conductor, glass industries, metal industries: ferrous & non-ferrous | 980-1450°C 1800-2640 °F |

|

| Type T thermocouple | Food monitoring, environmental sensors, used in strong magnetic fields | -200 - 350°C -328 - 660 °F |

|

Notes to the table above

- "Which Thermocouple is Right for Your Application" [info graphic], Pyrosales Pt Ltd., New South Wales, 4 Woodie Place, Padstow NSW 2211, PO Box 309, Australia, Tel: 1 300 737 976 & Tel: +61 2 9790 1040, Email: sales@pyrosales.com.au Website: https://www.pyrosales.com.au, Tel: NSW : 02 9199 5755 VIC : 03 9988 0945 QLD : 07 3171 8672 CHILE : +56 22 5031596

CHINA : 86 22 23708751 USA : 847 656 5258 retrieved 2017/07/21,

Pyrosales USA, 51 N. Ayer Street, Harvard IL 60033-2859 USA, Tel: 847-656-5258 Email: sales@pyrosales.us

original source: https://www.pyrosales.com.au/blog/cat/thermocouple/post/which-thermocouple-is-right-for-you

Website excerpt:

Pyrosales has operations in Sydney, Melbourne and Brisbane as well as in South America, China and the United States. - Thermometrics, THERMOCOUPLE TYPES & TEMPERATURE RANGES [PDF] Thermometrics Corporation, 18714 Parthenia St

Northridge, CA 91324 USA Tel: (818) 886-3755 also DBA

AeroGear Telemetry serving aerospace & military applications, retrieved 2017/07/21, original source: http://www.thermometricscorp.com/thermocouple.html

Website excerpts:

... calibration types are designed to deliver as close to a straight line voltage curve inside their temperature application range as possible

... The smaller the diameter,the faster the thermocouple responds. Grounding the junction also improves response time by approximately 50 percent based on the sensor achieving 63.2 percent of the final reading or to the first time constant. - Calibration types for thermocouples are specified by the American Society for Testing and Materials(ASTM) according to their temperature versus EMF characteristics in accordance with ITS-90,in standard or special tolerances.

Thermocouple Installation Instruction Manuals

- American Water Heater Co., THERMOCOUPLE REPLACEMENT INSTRUCTIONS - NATURAL GAS MODELS (All Models Except 30T) [PDF] (2005) American Water Heater company, Tel: 1-800-999-9515, Website: americanwaterheater.com - retrieved 2023/04/23, original source: americanwaterheater.com/media/42245/nat_tc_instr.pdf

- [1] American Water Heater, THERMOCOUPLE REPLACEMENT INSTRUCTIONS - NATURAL GAS MODELS (ALL MODELS EXCEPT 30T) [PDF] (older copy), American Water Heater, Johnson TN, Website: americanwaterheater.com, Tel: 1-800 999-9515, (no address given online) retrieved 10/23/2013

- A.O. Smith, "Residential Gas Water Heaters: Replacement Parts List, Models FCG/PCG 75-100 & CGX/PCGX/SGX/PSGX-75 Series 270", [PDF], A.O. Smith Water Products Company, 5621 W. 115th St., Alsip IL 60803 USA, Tel: 1-800-433-2545, Website: www.hotwater.com, Email: www.hotwater.com/parts, retrieved 15 March 2015, orginal source: http://www.hotwater.com/lit/partslists/psd3549.pdf

- GAC INSTALLING A K-TYPE THERMOCOUPLE [PDF] (2019) Governors America Corp. 720 Silver Street Agawam, MA 01001, USA Email: gac@governors-america.com Sales and Technical Support: (413) 233-1888 Web: https://www.governors-america.com/

- GAS WATER HEATER THERMOCOUPLE INSTALLATION INSTRUCTIONS [PDF] (FVIR) System Thermocouple Assembly Replacement Kit, generic gas water heater instructions, various sources

Excerpt: Only a qualified service person should service and repair heater. - Isspro, PYROMETER AND THERMOCOUPLE INSTALLATION INSTRUCTIONS [PDF] Isspro Inc, 2515 N.E. Riverside Way - Post Office Box 11177, Portland, Oregon 97211-1899 USA, Tel: 503-528-3400 / 800-888-8065 Web: www.isspro.com

- Partsfor THERMOCOUPLE REPLACEMENT INSTRUCTIONS [PDF] (2008) PartsFor.com, P.O. Box 141727, Grand Rapids, MI 49514 USA, retrieved 2022/07/28 original source: https://partsfor.com/pdf/thermocouple_instructions.pdf

- Precision Measurements, THERMOCOUPLE INSTALLATION & MAINTENANCE INSTRUCTIONS [PDF] Precision Measurements, 3715 Northcrest Road Suite #2 Atlanta, Georgia 30340

(770)-457-7099 www.precision-measurements.com E-mail: sales@precision-measurements.com , retrieved 2022/07/28, original source: http://www.precision-measurements.com/pdf/mineral-insulated-thermocouple/tc-installation.pdf - RADAK FURNACE THERMOCOUPLE REPLACEMENT INSTRUCTIONS [PDF] Luxel Co., PO Box 1879, 515 Tucker Ave.

Friday Harbor, WA 98250 USA Web:

www.luxel.com Phone: (360) 378‐4137

Email: radak@luxel.com

Excerpt:

The thermocouple in your RADAK furnace has been made, installed, and inspected with great care.

The junction, which is formed by spot-welding, is subject to failure due to mechanical or chemical stress.

Vibration or some metal vapors, such as zinc, will occasionally cause failure in these thermocouple materials. - ReoTemp, THERMOCOUPLE INSTRUCTIONS [PDF] Installation, Operating, and Maintenance Instructions Thermocouple and RTD Assemblies, Thermotemp Corp. 10656 Roselle St. - San Diego, CA 92121 USA, Tel: (858) 784-0710 Web: www.reotemp.com Email: sales@reotemp.com

- TSC THERMOCOUPLE INSTALLATION [PDF] Thermosensors Corporation, PO Box 461947, Garland TX 75046 USDA, Tel: 1-800-889-5478 Web: https://www.thermosensors.com/, retrieved 2022/07/28, original source: https://www.thermosensors.com/thermocouples/installation/

- Volbrecht, Art, GUIDELINES FOR GOOD THERMOCOUPLE PRACTICE [PDF] Watlow, St. Louis MO., in Heat Treating Progress, May/June 2007, pp. 48-51, retrieved 2022/07/28, original source: https://www.asminternational.org/documents/10192/1915068/htp00703p048.pdf/236107c7-ec38-40e6-8ecc-51a23dfefaa4

- Weil McLain, ERECTING INSTRUCTIONS, Series 1 Type D GAS BOILERS [PDF], Weil McClain Corporation, Michigan City Indiana,

Troubleshoot Thermocouple on Gas Fired Heating Equipment

Moved to THERMOCOUPLE DIAGNOSIS - PILOT WON'T STAY LIT - pilot light used to work but now keeps going out or won't stay lit

Thermocouple Installation SNAFUS

Moved to THERMOCOUPLE INSTALLATION SNAFUS - pilot light has never worked well

Research on Thermocouple Failure Causes

Moved to THERMOCOUPLE FAILURE RESEARCH

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2022-11-21 by InspectApedia (Editor) - why does my thermocouple need replacing so often?

@Don,

I don't know, Don, but there are some possible explanations I can suggest for the frequent replacement of a thermocouple on a gas fired Heating system.

One is that the thermocouple is not being correctly placed in the gas flame and is being replaced as defective when really it's an installation error.

Next is a similar error in which the installer doesn't adequately tighten the connection of the thermocouple at the gas valve. Again we find that sometimes installer makes the same mistake repeatedly so we keep replacing the part.

A third is that all of the thermocouples were bought from the same manufacturing run or a lot and is it effective product. One thing to try is being sure to go to a completely different source.

Finally we want to make sure that the problem is really the thermocouple and that we're not blaming it for another problem on the heating system.

On 2022-11-21 by Don

have a Wheel Mclean Boiler for gas heating ......the Thermo Coupling needs to be replaced every six months...WHY ?

On 2022-10-30 by InspectApedia (mod)

@Simon,

We need to find and read the product description and instructions for that thermocouple before commenting further. Follow up here. If you could post a photo that would be helpful.

On 2022-10-30 by Simon

I have a Cannon gas fire that has a thermocouple C00147880 , This has 2 wires that connect to a switch that operates when the gas valve is rotated.

Why does it need this because if there is no heat on the thermocouple then the gas will not flow? I assume this is an 'extra' safety feature that changes the thermocouple price from £10 to £80+? why is thermocouple wire always in a copper tube?

On 2022-06-08 by InspectApedia-911 (mod) - Copper wire on my Napoleon fire table severed

@Tom,

If by "copper wire" you refer to the small diameter copper tube that connects the flame sensor tip to the gas control valve, that whole system is sold as a single assembly, is not expensive, and is replaceable, as described above on this page. Please do take a look and let me know if you're left with further questions.

On 2022-06-08 by Tom

Copper wire on my Napoleon fire table severed so fire will not stay lit. Can I fix it or replace it?

On 2022-02-22 by Inspectapedia Com Moderator - What should wrap around the tip of the thermocouple?

@Anonymous,

I am GUESSING that you're asking where in the pilot flame should the gas control thermocouple sensor be positioned.

It should be in the center of the gas burner's pilot light flame.

From the page above:

The flame position or that of the thermocouple (or thermopile sensor tip) that must be immersed in the flame is often adjustable by loosening a mounting screw or on occasion by gentle bending of a metal bracket.

On 2022-02-22 by Anonymous

What should wrap around the tip of the thermocouple when correctly install in a gas water heater

On 2022-01-18 by Inspectapedia Com Moderator - Century unvented room heater model FN020401 faulty thermocouple

@Harvey,

That's probably what I'd try first: replace the thermocouple - after checking that the original was properly placed to sense the flame.

On 2022-01-18 by Harvey

I have a Century unvented room heater model FN020401 ser# 00045. I haven't used it for several years. I can get the pilot light lite, but when I start the main burner it runs for a few seconds then shuts off everything. Is this a faulty thermocouple?

On 2022-01-06 by Inspectapedia Com Moderator

@Jonathan Apperley,

Thank you.

We've worked hard on this material for decades, so are really grateful when a reader finds it useful and trustworthy.

We also welcome your photos, questions, criticism or suggestions.

On 2022-01-06 by Jonathan Apperley

Great post! Covered a lot of information here and as someone who regularly works with thermocouples regularly within a different industry, even I learned something.

On 2021-07-28 by inspectapedia.com.moderator - water heater with a electric ignition keeps going out

@Bobby Jones,

If your heater uses electronic ignition, it ignites the burner automatically when heater temperature drops. It does not use a standing pilot flame.

What are the water heater brand and model?

On 2021-07-28 by Bobby Jones

I have a 3 month old water heater with a electric ignition I can get the pilot going as soon as I let go it goes out. What can I do?

On 2021-03-04 by (mod) - white box on wall by furnace kept beeping so I threw it away!

@Jesse MacLean,

Watch out: that sounds to me like a carbon monoxide monitor alarm - if so, potentially fatal carbon monoxide gas is present; people in the building could be killed.

Leave the heater off and do not try to run it before it has been inspected for safe proper operation and repaired as necessary.

If you ignore this advice you could be responsible for many deaths including your own.

On 2021-03-04 by Jesse MacLean

I think I’ve got a bad thermocouple. Every time my furnace turns on this white box on the wall starts making an ear piercing beep. It has a number display on it and when it starts beeping it is always some random number between 50 and 100, but the number steadily increases as time goes by.

Not sure when it stops counting up because it’s so loud it gives you a headache so eventually you have to go outside. When I say it’s loud I am talking about realllly, reallly loud. It’s literally so loud that you will get dizzy if you stay inside listening to it for more than 30-45 minutes.

I tried unplugging the dang thing and throwing it in the dumpster but it keeps going off even when it isn’t plugged in so the neighbors heard it and called the landlord out and he came out and put a new one in.

I threw that one away too but the landlord is a jerk and once he found out he came back and put another one in and this time he put a locked cover over it so I can’t even throw it out.

He is a real cheap scape. Probably bought the thing second hand knowing it was broken and would be constantly beeping and didn’t give a hoot since he saved a few bucks.

Honestly I don’t even know why it is neccessary because the furnace worked just fine and still put out heat even after I chucked the beeper box in the dumpster. Any advice? I’m at my wits end.

On 2021-01-25 - by (mod) - flame height or strength on a gas burner pilot light is not adjustable except ...

Martin:

The flame height or strength on a gas burner pilot light is not itself usually adjustable, though if the pilot orifice is clogged you might need to clean or replace that part to get the proper flame size.

The flame position or that of the thermocouple that must be immersed in the flame are often adjustable by loosening a mounting screw or on occasion by gentle bending of a metal bracket.

However on some older gas appliances like gas ranges and stoves, a small set screw near the pilot can adjust the flame height.

On 2021-01-25 by Martin O' Malley - How do you adjust the flame on the pilot

How do you adjust the flame on the pilot

On 2020-10-07 - by (mod) - successfully replaced the thermocouple

Karen

Good for you kiddo (I'm older than you) for being able to replace the thermocouple.

The most-common snafus I've encountered when a new thermocouple did not work have been

1. the end of the thermocouple that screws into the gas valve was not fully seated

2. the end of the thermocouple that senses the flame was not precisely positioned in the proper portion of the pilot or burner flame

But in any event these are pretty generic products; if you found one that worked, we 're in good shape for the coming cold weather (if it ever gets really cold again).

On 2020-03-28 - by (mod) - gas valve won't open: black wires at the thermocouple?

Karen

Karen

Take a look (and post a photo) of where those two black wires lead. I am GUESSING that they lead to a couple of spill switches that might be located on the draft hood of your heater or right near the burner opening.

Those devices sense dangerous spillage of flue gases, are usually heat-activated, and some models require that the switch be manually-reset by pressing a reset button on the switch after it has cooled.

See details at FLUE GAS SPILL SWITCH TRIPPING & RESET

Let me know if that helps you out.

[Click to enlarge any image]

On 2020-03-27 by Karen

Thank you for your answer of 5/2/19 to my on going problem.

This thermocouple has a little side thing on the connector that has two black wires. Now I cannot get the pilot to even try to light. I seem to remember reading something about them being for safety or something.

I had to leave the door open to the heater because the connector sticks out too far and when moved the pilot goes out.

A little giggle and it would work for awhile. Something is loose inside, I think.

Any advice. I could replace the thermocouple again, but now I cannot finknob colors may be red not black) d one with that extra wire thing. Do I have to have that? I have added a picture [above] for you. Thank you.

On 2020-01-27 - by (mod) - do I need to insulate around a thermocouple?

That's not an explanation that i understand. After all, the thermocouple is in a flame.

Try replacing it and be sure the new one is properly placed.

On 2020-01-27 by jeff Kann

the building i am trying to heat just when used gets so cold i think the thermocouple gets to cold to stay on, what do i do. insulate it?

On 2020-01-02 - by (mod) - generic thermocouple replacements

Thermocouples are pretty much a generic replacement item. Just check the length of the tubing needed. It's better not to have a lot more to me than you need just for Simplicity.

Watch out if you don't know how to make these connections you could make your system unsafe.

On 2019-12-31 by jack cantrell

will about any thermocouple work on all ventless fire places mine is majestic v32

On 2019-11-12 - by (mod) - What type of thermocouple use for mini flare?

Bernie

Apologies but while Thermocouples are quite standard in their threads and fittings across gas appliances, I don't know what product is referred to by "mini flare"

Perhaps you could attach product details and a photo? I'm not aware of any thermocouple on gas appliances that use a flare fitting.

On 2019-11-12 by Bernie

What type of thermocouple use for mini flare?

On 2019-10-23 - by (mod) - pilot light is on but the main burner doesn't light?

Common causes for the refusal of a gas burner to light when the pilot is on include a bad gas valve or most likely a defective thermocouple or thermocouple connection.

On 2019-10-23 by Leonard

What. If the pilot light is on but the main burner dosent light?

On 2019-05-02 - by (mod) -

Check the thermocouple connection at the gas valve

Watch out: also check for lack of combustion air - your heater may include an oxygen sensor that shuts down the system if there is insufficient combustion air - as that risks fatal CO poisoning or poisoning from lack of oxygen in the room.

On 2019-02-15 by Karen

Replaced the thermocouple on my elderly Williams dual wall heater a couple of years ago. Lately it has started acting up. I don't have any trouble lighting the pilot. The flame is blue and looks a nice size.

Then the heater works cycling on and off as you would expect. At some point, the burner goes off and the pilot light is also out and I have to light it again.

Sometimes this takes 30 minutes, sometime several hours. I have used canned air to clean and pushed and pulled everything. Hope someone has some wisdom for me. Thank you.

...

Continue reading at GAS BURNER PILOT LIGHT PROCEDURE or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see THERMOCOUPLE TROUBLESHOOTING FAQs - questions & answers posted originally at this article

Or see these

Recommended Articles

- FLUE GAS SPILL SWITCH TRIPPING & RESET

- GAS BURNER FLAME & NOISE DEFECTS

- GAS BURNER SOOT CAUSE & CURE

- GAS BURNER PILOT LIGHT PROCEDURE

- GAS FIRED HEATING BOILER PROBLEMS

- GAS FIRED WATER HEATERS

- GAS FIREPLACES & GAS LOGS

- GAS IGNITER DIAGNOSIS & REPAIR

- GAS PILOT WON'T STAY LIT

- GAS REGULATORS & APPLIANCE / HEATER CONTROLS

- THERMISTORS

- THERMOCOUPLE REPAIR / REPLACEMENT

Suggested citation for this web page

THERMOCOUPLE REPAIR / REPLACEMENT at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to HVAC THERMOSTATS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.