Heating Boiler, Gas: Defects List

Heating Boiler, Gas: Defects List

Heating Boiler Inspection Education

- POST a QUESTION or COMMENT about gas fired heating boilers

Gas heating boiler defets list for home inspections: This article lists significant gas fired heating boiler defects, definitions, and home inspection education topics.

This article series, beginning at BUILDING DEFECTS LISTS, provides lists of common building defects and basic defect knowledge that also outline recommended curriculum content for home inspector education. The building defects and inspection points listed in these articles also guide homeowners and home buyers to building areas that merit careful attention and often point areas of safety concern or important maintenance and repair tasks.

Watch out: these inspection lists do not list all possible defects for the systems discussed, and not all home or building inspectors will examine all of the items listed here.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Home Inspection Education Curriculum - Heating, Gas Boilers

4. HEATING, Gas Fired Boilers: Inspection Recommendations & Typical Defects Lists

4.1 Gas Fired Warm Heating Boilers Inspection Recommendations & Education

4.1.1 Knowledge Base for Inspecting Gas Fired Heating Boilers - Hydronic Systems

1. Describe the function of residential heating systems.

2. Describe the common heating fuels (gas, oil, propane, electricity, wood).States GAS above ??

3. JDG

3. Describe the combustion process with reference to the fire triangle, combustion air, ignition, and venting.

4. Describe three methods of heat transfer(radiation, convection, conduction) and how each apply to residential heating systems.

5. there is none.

6. Describe the common types of heating equipment (furnaces, hot water boilers, steam boilers, space heating, radiant heating).

7. List the materials, function and location for the components of a gas fired forced air furnace including ? fuel delivery system, burner, gas valve, pilot light, thermocouple, combustion air supply, heat exchanger, cabinet, fan (blower, air handler), fan control, high temperature limit switch, thermostat, draft hood, vent connector (exhaust flue, C-vent, B-vent, vent pipe, stack pipe, flue pipe, chimney connector, breeching), filter, electronic air cleaner, humidifier, duct system, registers, grill, induced draft fan, electronic ignition system, condensate handling system, vent damper.

8. Differentiate between conventional, mid efficiency and high efficiency gas furnaces. Include a description of the normal operating cycle for each.

9. Describe the features of adequate installation and repair technique for gas fired forced air furnaces.

10. Define the following terms with respect to gas fired heating systems: gas pressure regulator, gas meter, drip leg(dirt pocket), flex connectors, combustion air, draft air, dilution air, circulating air, spillage(back drafting, down drafting), natural gas, BTU content of natural gas, monoport burner, multi port burner, cross over igniter refractory (firepot),

Norrmally only in oil fired systems) JDG gas valve, pilot light, thermocouple, fan/limit switch, heat shield(flame roll out shield), heat exchanger, indirect fired system, direct fired system, draft hood, blower(house fan, furnace fan, air handler, furnace blower), Fan door safety relay.

JDG, up flow furnace, down flow furnace, horizontal furnace, summer switch, fan compartment interlock switch, thermostat, heat anticipator, vent connector, supply plenum, return plenum, filter, supply duct system, return duct system, supply registers, return grills, electronic air cleaner, humidifier, input capacity, output capacity, bonnet capacity, steady state efficiency, seasonal efficiency, steady state losses, off cycle losses, stack effect, AFUE, separation of circulating and combustion air.

11. Define the following terms with respect to mid and high efficiency gas furnaces: vent damper, intermittent pilot, direct spark ignition, hot surface ignition, flame rectification, natural draft burners, induced draft burners, forced draft burners, pre-purge, side wall venting, sealed combustion, direct vent, mid efficiency, high efficiency, condensing furnaces, latent heat of vaporization, neutralizer, differential pressure switch, heat switch(spillage switch), blower cover interlock, pulse combustion, combination furnaces(water heater and furnace), tempering valve (mixing valve).

12. Outline the life expectancies for gas fired forced air furnaces.

13. Identify the codes and standards which apply to gas fired appliances and warm air heating systems in your area.

4.1.2 Inspection Skills for Gas Fired Heating Boilers

1. Describe the inspection procedure for conventional, mid efficiency and high efficiency, forced air gas furnaces.

2. Identify the following common defects listed on the next page.

3. Describe the implication of each defect.

4. Identify safety issues for the inspector and occupant of the house (gas explosion, carbon monoxide poisoning, injury due to moving parts).

5. Communicate findings to client verbally and in writing, recommending corrective action where needed.

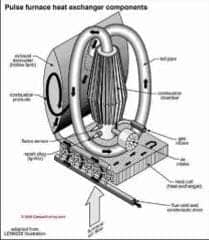

Sketch above of a pulse furnace heat exchanger is provided courtesy of Carson Dunlop Associates & appears in their Home Reference Book.

GAS Burner for Boilers: TYPICAL DEFECTS

Gas Burner & Venting Defects

Gas Meters, Defects, Visible or by Testing

- Damaged

- Leaks

- Not protected from vehicle impact

- In contact with or partly buried in soil

- Askew

- Gas shut off and locked

- Icing

- Leak tracks or stains

- Mechanical Damage

- Inaccessible

- Poor Location

Heat Shield Defects on Gas Boilers, Heaters, Furnaces

- Loose

- Missing

- Rust

- Scorched

Venting System Defects, Gas Fired Heaters

- Rust, rust perforated, damaged, leaky

- Under-sized

- Connector extends into chimney

- Draft hood spillage or backdrafting

- Draft hood wrong height

- Draft hood upside down

- Draft hood obstructed

- Inadequate clearance from combustibles

- Inadequate combustible clearance

- Plastic - recalled Plexvent Ultravent etc.

- Wrong slope

- Too long

- Vent Connector or Flue Segments connected wrong way or upside down

- Poor manifolding

- Inadequate support, or loose

- Wrong materials (aluminum)

- Poor connections

- Rust, dirty, obstructed

- Spillage switch problems - damaged, loose, removed, inoperative (not visible)

- Vent connector too long

- Vent connector too big or too sma

Gas Fired Heater Piping Defects

- Also see GAS PIPING, VALVES, CONTROLS for details of these topics.

- Improper material

- Copper tubing not properly labeled

- Improper connections

- Inadequate or loose support

- Leaks detected, odors

- Leak indicators (stains)

- Missing shutoff valves

- Shutoff valves wrong location (only inside cabinet)

- Missing drip leg or dirt leg [not required all jurisdictions]

- Piping run in chimney

- Piping run in ducts

- Plastic pipe exposed to damage

Mid & High Effficiency Gas Heaters: Boilers, Furnaces

- Rust Corrosion. JDG

- Airflow proving switch problems

- Condensate problems

- Electronic ignition problems

- Excess temperature rise

- Heat exchanger problems - rust, scorching, leaks onto

Gas Fired Boilers or Furnaces: Combustion Air Defects

- Inadequate combustion air

- Combustion air exposed to debris, lint, dryer exhaust, pets

- Poor vent location, arrangement

- Poor combustion air intake location

- Vent damper stuck, blocked, closed-off, subject to snow cover

Gas Burner Inspection Points & Defects

- GAS BURNER FLAME & NOISE DEFECTS

- GAS BURNER SOOT CAUSE & CURE

- GAS BURNER PILOT LIGHT PROCEDURE

- Induced draft fan problems

- Delayde ignition Delayed ignition

- Watch out: dirt or soot indicating unsafe burner operation

- Flame wavers when fan comes on

- Gas leaks: odors, tracking stains, tested, confirmed, suspected

- Shut down, red-tagged, inoperative

- Poor flame colour or pattern

- Rust or corrosion, leaks onto heat exchanger (furnaces) from cooling coil

- Scorching

- Short cycling

4.3 Hot Water Heating Boilers, Typical Defects Lists

(Burners are not covered in this section since they have been covered earlier)

4.3.1 Knowledge Base for Gas Fired Boilers

1. Describe the function of a hot water (hydronic) heating system.

2. Describe open and closed heating systems.

3. Describe four types of distribution piping (series loop, 1-pipe system, 2-pipe system - direct return, 2-pipe system - reverse return).

4. List the materials and components of a typical hot water heating system including fuel storage and supply system, burner, combustion air supply, venting, cabinet/body, heat exchanger, controls, expansion tank, pump (circulators), pipe, radiator, convector, baseboard, radiant heating.

5. Describe the features of adequate installation and repair technique for hot water heating systems.

6. Outline the advantages and disadvantages of hot watering heating relative to forced air heating.

7. Outline the differences between boilers and furnaces, including the normal operating cycles.

8. Define the following terms with respect to hot water boilers: convection, conduction, radiation, super heated water, pressure relief valve, high temperature limit switch, low water cut-out, backflow preventer, pressure reducing valve (automatic water makeup), automatic air vent, primary control pump(circulator), zone control, outdoor air thermostat, flow control valve, isolating valve, tankless coil, radiator bleed valve, radiator control valve, air separator (air scoop), aquastat, open expansion tank, closed expansion tank, diaphragm (bladder) expansion tank, side arm heater, indirect water heater, mixing valve(tempering valve), condensing boilers.

9. Outline the life expectancies of boilers made of various materials.

10. Identify the codes or standards which apply to hot water heating systems in your area.

4.3.2 Inspection Skills for Gas Fired Boilers

1. Describe the inspection procedure for hot water heating systems.

2. Identify the following common defects listed on the next page.

3. Describe the implication of each defect.

4. Identify safety issues for the inspector and occupant of the home (steam explosion, combustion product poisoning, electric shock, physical injury).

5. Communicate findings to client verbally and in writing, recommending corrective action where needed.HOT WATER BOILER TYPICAL DEFECTS

Gas Fired Boiler Heat Exchanger Defects

- Clogged

- Damaged

- Leaks

- Dirty

- Rust

- Scorching

Room Thermostat Defects - Gas Fired Hot Water Heat

- Loose

- Not level

- Heat anticipator problems

- Excess temperature rise

- Poor adjustment or calibration

- Poor location

Boiler Cabinet Defects

- Combustible clearance

- Mechanical damage

- Missing components

- Obstructed air intake

- Leaks

- Rust

- Scorching

- Rust

Gas-Fired Boiler Air Vent Defects

- Too small

- Waterlogged

- Inoperative, damaged

- Leaking

- Poor location for tank

- Poor discharge location for open tank

Hot Water Heating Circulator Pump or Relay Defects - Gas Fired Heating Systems

- Missing

- Obstructed

- Hot

- Inoperative

- Leaks

- Noisy

Gas-Fired Heating Boiler Expansion Tank Defects

- Improper position, location, type

- Leaks

- Noisy

- Waterlogged [DF]

Gas-Fired Heating Boiler Primary Control Defects

- Burn marks visible on circuit board or other location

- Buzzing relays

- Damaged (visible, e.g. broken reset button)

- Inoperative

- Set incorrectly

- BOILER PRESSURE & TEMPERATURE SETTINGS

Gas-Fired Heating Boiler Isolation Valve Defects

- JDG autofill mehanisms

Gas-Fired Heating Boiler Pump Control Defects

- Set incorrectly

Gas-Fired Heating Boiler Pressure Relief Valve Defects

- Capped

- Leaking

- Missing

- No piped extension

- Inoperative

- Pipe too small

- Pipe threaded, capped or corroded at the bottom

- Pipe dripping or leaking

- Poor location

- Routed to non-visible location

- No Tundish (some jurisdictions)

Gas-Fired Heating Boiler Zone Control Defects

- Inoperative

- Set wrong

- Leaking

- Wrong size

Gas-Fired Heating Boiler Outdoor Air Defects

- inadequate combustion air

Gas-Fired Heating Boiler High Limit Switch Defects

- Inoperative

- Defective, not wired correctly

- Missing

Gas-Fired Heating Boiler Flow Control Valve Defects

- Set too high

- Inoperative

Gas-Fired Heating Boiler Low Water Cutoff Control Defects

- Leaks

- Inoperative

[not required in all jurisdictions]

Gas-Fired Heating Boiler Isolation Valve Defects

- Leaking

- Inoperative

Gas-Fired Heating Boiler Backflow Preventer Valve Defects

- Leaks

- Rust

- Installed backwards

- Leaking

- Missing

Gas-Fired Heating Boiler Pressure Reducing Valve / Water Feed Valve Defects

- Installed backwards

- Leaking

- Set improperly

- Bypassed

- Missing

- Set too low

Mid & High Efficiency Gas-Fired Heating Boiler Defects

- Inoperative

- Cabinet problems

- Combustion air and venting problems

- Leaking

- Condensate handling problems

- Fuel supply and burner problems

- Heat exchanger problems

- Ignition problems

- Induced draft and forced draft fan problems

- Safety and operating control problems

- Also see

CONDENSING BOILERS/FURNACES

CONDENSING BOILERS/FURNACES DAMAGE

DIRECT VENTS / SIDE WALL VENTS

Hot Water Heating Piping Defects on Gas Fired Heating Boiler Systems

- Crimped

- Leaks

- No insulation

- Poor support

- Rust

Gas-Fired Heating Boilers & Radiant Heating Systems

- Balancing valve problems

- Too small

- Bleed valve problems

- Cool rooms or parts of rooms

- inoperative?

Gas-Fired Hot Water Heating Radiators, Convectors, Baseboards: Defects

- Damaged baseboard fins

- Noisy

- Cold

- Valves inoperative

- Air bleeder missing, leaky, damaged

- Bleed valve problems

- Missing covers

- Missing or removed heating sections or radiators

- Leaks

- Obstructed airflow

- Poor location

- Rust

- Too small (cool rooms)

Tankless Coil on Gas-Fired Heating Boiler, Defects

- Balancing valve problems

- Leak

- Cold

- Rust

- Poor hot water pressure or flow (clogged?)

These curriculae and building defect lists are based on smilar curriculum documents first prepared by Joe Scaduto, an ASHI member who prepared course material for Northeastern University's Building Inspection Certificate program in 1988, subsequently by DF, InspectApedia's editor, for New York University ca 1988 and later, with others, recommended to ASHI, the American Society of Home Inspectors. ASHI did not adopt this material though currently that association as well as others offers other material

The curriculum and lists of defects are informed by additional analysis of the process of home inspection that was developed beginning Calgary, AB for Canadian and U.S. home inspector education and certification examinations in 1997. Other early contributors to home inspection education in the U.S. and Canada include Dr. Jess Aronstein, Alan Carson, Mike Casey, Mark Cramer, John Cox, Dwight Barnett, Douglas Hansen, Rick Heyl, Larry Hoytt, Bill Merrill, Kevin O'Malley, Dennis Robitalille, Keith Peddie, Pat Porzio, Roger Robinson.

Watch out: these inspection lists do not list all possible defects for the systems discussed, and not all home or building inspectors will examine all of the items listed here.

...

Continue reading at BOILERS, HEATING or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ANTIQUE HEATERS STILL in USE for an example of an antique but still-used gas fired floor/wall heater

- ARTICLE INDEX to HEATING BOILERS

- BOILERS, HEATING

- CARBON MONOXIDE WARNINGS: HOME HEATERS

- GAS PIPING, VALVES, CONTROLS

- HOME INSPECTOR EDUCATION

Suggested citation for this web page

DEFECTS LIST - HEAT BOILER GAS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to BUILDING & HOME INSPECTION

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com 11/06

- Roger Hankey is principal of Hankey and Brown Inspections, Winter Park, CO. Mr. Hankey is a past chairman of the ASHI Standards Committee and served in other ASHI chapter and national leadership roles. Mr. Hankey is a National Radon Proficiency Program certified measurement professional and a Level II infrared thermographer. Contact Roger Hankey at: 970-393-6604 - rogerhankey47@gmail.com . Website: www.HankeyandBrown.com Mr. Hankey is a frequent contributor to InspectAPedia.com.

- Arlene Puentes [Website: www.octoberhome.com ] , an ASHI member and a licensed home inspector in Kingston, NY, and has served on ASHI national committees as well as HVASHI Chapter President. Ms. Puentes can be contacted at ap@octoberhome.com

- Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- Building Pathology, Deterioration, Diagnostics, and Intervention, Samuel Y. Harris, P.E., AIA, Esq., ISBN 0-471-33172-4, John Wiley & Sons, 2001 [General building science-DF] ISBN-10: 0471331724 ISBN-13: 978-0471331728

- Building Pathology: Principles and Practice, David Watt, Wiley-Blackwell; 2 edition (March 7, 2008) ISBN-10: 1405161035 ISBN-13: 978-1405161039

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.