Hot Water Mixing Valve & Scald Protection Valve Inspections

Hot Water Mixing Valve & Scald Protection Valve Inspections

Inspection points for hot water safety controls & valves

- POST a QUESTION or COMMENT about anti scald and mixing valve or water blender valve defects & inspection procedures

Safety & functional inspection of anti scald valves & mixing valves - water blender valves.

This article describes key safety inspection points that should be examined when inspecting building hot water supply anti-scald protection and tempering valve or mixing valve or temperature compensating valve installations.

We discuss temperature or scalding safety, valve adjustment, and leak concerns at mixing valves, and we include manufacturer's instructions & warnings about mixing valve installation, safety, and periodic inspection & maintenance.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

How do we Inspect Mixing Valves or Anti-Scald or Tempering Valves

Watch Out: are there temperature control devices installed on the building hot water supply system? In most jurisdiction scald protection is required for residential properties but it may not be specified by local codes for commercial properties.

When you find the temperature mixing or anti-scald device, check to see if the temperature controls properly set?

[Click to enlarge any image]

Check the temperature control settings on the device and where appropriate, actually measure hot water output temperature at the fixtures closest to hot water supply in order to assure that the mixing valve has been set to protect the building occupants from scalding.

Remember that while these valves may show a target temperature on the valve setting knob, the actual water temperature that comes out of a building faucet or tap will vary and may be hotter or cooler than the actual temperature set.

This is not precise lab-grade equipment capable of controlling water temperature precisely, and more, the length of pipe run between the hot water source and the building faucet or fixture will affect the temperature of water received there. A long run of un-insulated hot water pipe will deliver cooler water than a well-insulated water supply pipe of any length.

Leaks Second:

See TANKLESS COIL / HOT WATER COIL LEAKS for a detailed discussion of how to recognize, evaluate, and repair leaks at tankless coils on heating boilers

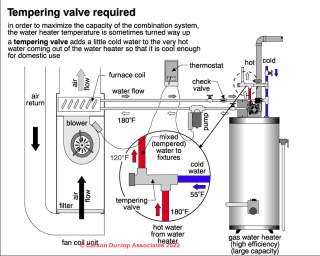

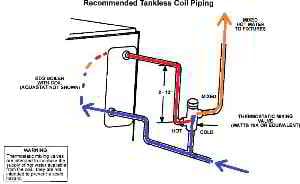

At above left we illustrate the typical piping arrangement into and out of a tankless coil water heating system. Cold water is piped to an inlet marked "COLD" and building hot water supply piping is connected to the tankless coil outlet marked "HOT".

This tankless coil piping example from Crown Boilers indicates the use of a mixing valve or anti-scald valve right at the heating boiler. The company includes an interesting warning reading as follows [Quoting - Crown BDS Installation Manual]

WARNING: Thermostatic mixing valves are intended to increase the supply of hot water available from the coil. They are not intended to prevent a scald hazard.

Typical Hot Water Supply Temperature Control Valve Operating Range & Adjustment Settings

The following table is excerpted from ANTI SCALD VALVES & TEMPERATURE CONTROL / MIXING VALVES the home page for this topic:

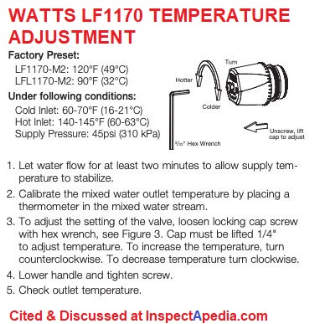

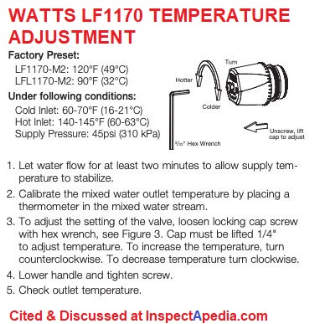

Using the modern Watts Regulator Co. Series LF1170 / LFL1170 Hot Water Temperature Control Valve instructions as an example, these valves control water temperature in the following ranges:

Table of Hot Water Mixing Valve Output Temperatures [Watts Series LF1170 & LFL1170] |

|||||

| Hot Water Mixing Valve Model | Cold Inlet Temperature | Hot Inlet Temperature | Factory Preset Outlet Temperature | Output Temperature Adjustment Range | Water supply pressure |

| Watts LF1170-M2 | 60-70 °F (16-21 °C ) | 140-145 °F (60-63 °C) |

120 °F (49 °C) | 90-160 °F (32-71 °C) | 45 psi (3.15 bar) |

| Watts LFL 1170-M2 | 90 °F (31 °C) | 60-120 °F (16-49 °C) | |||

Notes to the table above

The right-most "water supply pressure" number refers to the pressure at which these temperature readings will be expected for the mixing valves illustrated.

The right-most "water supply pressure" number refers to the pressure at which these temperature readings will be expected for the mixing valves illustrated.

Source: "Instructions Series LF1170 and LFL1170 Hot Water Temperature Control Valves", Watts Regulator Co. (2013)

See this current documentation:

- Watts Series LF1170 and LFL1170 Hot Water Temperature Control Valves INSTALLATION INSTRUCTIONS [PDF] Installation, operating, and adjustment instructions for the LF1170 and LFL1170 mixing valves.

- Watts Series LF1170 and LFL1170 Hot Water Temperature Control Valves SPECIFICATIONS [PDF] (2019), Watts Regulator Co. (2013), USA Tel: (978) 688-1811, Fax: (978) 794-1848,

Website: www.watts.com,

Canada: Tel: (905) 332-4090, Fax: (905) 332-7068, Website: www.watts.ca

Excerpt: This 1 inch lead free hot water control valve is designed for installation on water heating equipment to provide tempered water to point-of-use fixtures and is ideal for radiant heat applications.

The double throttling design combines hot and cold water control for a sensitive response to water temperature changes in the mixing chamber.

It consists of a lead free brass body, solder union connections, solid wax hydraulic principle thermostat, integral filter washers and check valves, virtual shutoff upon loss of cold water supply, and a locking mechanism for the temperature setting.

The maximum pressure is 150 psi (10.3 bar). The adjustable field range temperature is 60 to 120 degrees F (16 to 49 degrees C).

Anti Scald or Water Merge Valve Basics from Carson Dunlop Associates

- Carson Dunlop Associates, THE IMPORTANCE OF THERMOSTATIC MIXING VALVES TO PROTECT AGAINST SCALDING: Part ONE [PDF] Carson Dunlop Associates, School of Home Inspection, retrieved 2022/08/14, original source: https://www.carsondunlop.com/training/resources/the-importance-of-thermostatic-mixing-valves-to-protect-against-scalding-part-one/

Excerpt:

Anyone that has been scalded knows how painful it can be. When water is hot, it doesn’t take long for flesh to burn, and children’s skin burns more quickly. Also, at higher risk areolder people who react more slowly, and are more susceptible to burns as a result.

[See details at TABLE OF SCALDING TEMPERATURES & TIMES]

As inspectors, our home inspector training teaches us about important components like this to provide advice that will protect our clients’ well-being.

Carson, Dunlop & Associates Ltd, 120 Carlton Street Suite 407, Toronto ON M5A 4K2. (416) 964-9415 1-800-268-7070 info@carsondunlop.com.

Home Inspection Training: Tel: 866-586-6855 - Email: training@carsondunlop.com - Carson Dunlop Associates, THE IMPORTANCE OF THERMOSTATIC MIXING VALVES TO PROTECT AGAINST SCALDING: Part TWO [PDF] Carson Dunlop Associates, School of Home Inspection, retrieved 2022/08/14, original source: https://www.carsondunlop.com/training/resources/the-importance-of-thermostatic-mixing-valves-to-protect-against-scalding-part-two/

Except:

Due to the safety importance of this issue, ensure that the home inspector training program you select includes training on thermostatic mixing valves, so that you can provide the necessary advice for your clients.

Now that we know how pressure balanced and thermostatic control valves work, we can take a look at why thermostatic mixing valves are the solution.

Best Practices Guide to Scald Protection for Bathrooms, Tubs, Showers

Look for the presence of anti-scald protection at the point of use of hot water in buildings and make the same inspection and tests of temperature we just cited above.

Look for the presence of anti-scald protection at the point of use of hot water in buildings and make the same inspection and tests of temperature we just cited above.

Illustration: The Watts LF1170 or LFL1170 temperature control valve. Temperature an be adjusted by loosening a hex screw in the valve cap and rotating the cap - as described above.

At the plumbing fixture outlet hot water temperature must be at or below the highest temperature allowed by local building codes. These temperature specifications vary by U.S. state and in Canada.

Though 120 °F is a common upper temperature limit at the fixture, some states such as California specify a lower number (105 °F) and prison systems also have specific requirements.

See TABLE OF SCALDING TEMPERATURES & TIMES - where we explain how long it takes for hot water to cause a burn and where we cite regulations about water temperature control and anti-scalding requirements.

In that article we include a photo of a typical water heater label warning about scalding temperatures, implying that this option is one to consider.

Watch out: it can be confusing listening to plumbers, home inspectors, and building supply sales staff who toss around terms like "mixing valve", "tempering valve", and "pressure-balancing valve" a bit loosely, all referring to ways to avoid scalding burns at plumbing fixtures, but not all working the same way.

There are several approaches to controlling hot water temperature to avoid scalding burns:

The high temperature limit control on the water heating device itself can be set to prevent scalding water from being produced.

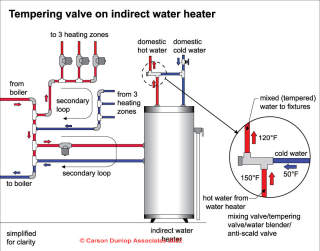

A point of supply pressure balancing valve or automatic mixing valve (or a manual mixing valve) can be installed at or near the water heater, or at the tankless coil or other hot water source so that scald protection is provided even if the water heater is set to a high temperature.

This approach is sometimes used to obtain more total hot water as we discuss at

MIXING VALVE IMPROVES HOT WATER QUANTITY and detail

at HOT WATER IMPROVEMENT.

This approach is further reviewed by Steven Bliss

at WATER PRESSURE BALANCING VALVES

An temperature-sensing thermostatic mixing valve or anti-scald device can be installed at or near the water heating device so that even if the water heater is set to a high temperature (to obtain more total hot water as we discuss

This approach is illustrated and explained

at BUILT-IN FIXTURE ANTI-SCALD VALVES and is discussed further by Mr. Bliss

at THERMOSTATIC MIXING VALVES As noted in Chapter 6 of Best Practices Guide to Residential Construction:

There are many styles of mixer valves in tubs and showers, but all should have some sort of protection against scalding. The young and elderly are at greatest risk due to thinner skin and slower reaction times.

More than 35,000 children, most under age six, are treated each year in emergency rooms for tap-water scald burns, according to the National Safe Kids Campaign.

A child exposed to 140°F water for as little as three seconds can sustain a third-degree burn requiring hospitalization and skin grafts.

Although most scald burns occur in the kitchen, according to the Consumer Product Safety Commission, the most severe scald burns are caused by water flowing into the tub or shower. In response, many state and local codes now require antiscald protection in residential tubs and showers.

Many organizations advocate setting water heaters to no more than 120°F, which gives bathers significantly more time to move away or adjust the temperature before a burn occurs. While this strategy is helpful, it is not always reliable and can cause other problems:

Noncompliance: many homeowners turn the thermostats up to increase supply.

Water heater thermostats are often inaccurate. The ANSI standard for gas water heaters allows the temperature to vary by plus-or-minus 10°F.

Stacking effect: water at the top of a gas water heater can exceed the set point by as much as 30°F.

MIX VALVE SCALD PROTECTION, Best Practices, includes excerpts or adaptations from Chapter 6 of Best Practices Guide to Residential Construction (Steve Bliss, J Wiley & Sons) , adapted courtesy of Wiley & Sons and written by Steven Bliss.

Inspect for the Presence of Point of Supply Water Pressure-Balancing Valves

These anti-scald devices automatically adjust the water pressure to maintain the mix of hot and cold water to within 2°F to 3°F of where the user set the shower control. If cold water is diverted to a flushing toilet or other appliance and the pressure drops, the valve automatically reduces the hot water flow proportionately to maintain the temperature.

If the cold water pressure plummets or stops altogether, the flow is reduced to a trickle.

To guard against someone accidentally turning the shower valve to scalding temperatures, these valves typically use a temperature limit stop that prevents the user from turning the shower control past a set point—typically set at or below 120°F.

A check valve is required on the cold water side to prevent backflow, and a hot-water expansion tank is recommended to prevent excessive pressure on the hot water side.

The other type of thermostatic valve is built into some high-end showers (Figure 6-54) courtesy of Steven Bliss, Best Construction Practices author. These devices allow the user to set the temperature on a dial when showering.

The unit will compensate for changes in either pressure or temperature to maintain a constant delivery temperature and flow rate. If the cold water fails or the tempered water is still too hot for any reason, the unit will shut off the flow.

As with the pressure-balancing valve, the installer sets a temperature limit stop to prevent the user from turning the shower control to scalding temperatures. We illustrate this approach as it is installed in a modern bathroom in Molde, Norway

at BUILT-IN FIXTURE Anti-Scald Valves.

Retrofits to Avoid Scalding Burns at Plumbing Fixtures

In retrofits, point-of-use devices can be installed by a plumber or homeowner to limit water temperatures to 120°F. These include antiscald showerheads, as well as point-of-use devices that fit into individual plumbing fixtures, such as showerheads and bath and sink faucets.

For example, MemrySafe and ScaldShield (Antiscald Inc.) are inexpensive retrofit devices that reduce the water flow to less than 1/4 gallon per minute when the water temperature at the faucet or showerhead exceeds 120°F. These devices do not regulate temperature or pressure, but do offer protection against serious burns.

Mixing Valve Installation Safety Warnings From the Manufacturers

Watch out: read the installation instructions from the manufacturer of the product you are installing, both to make sure it's installed properly and thus will work as expected, and also so that you understand what to expect by way of hot water temperature control the product handles.

At TANKLESS COIL INSTALLATION PROCEDURE where we recommend the use of mixing valves we quote this warning from the Crown Boiler Company:

WARNING: Thermostatic mixing valves are intended to increase the supply of hot water available from the coil. They are not intended to prevent a scald hazard.

Similarly, the Watts Regulator Company's instructions for the installation of the Series LF1170 & LFL 1170 Hot Water Temperature Control Valves includes this warning: [Bold font is our emphasis]

WARNING: FAILURE TO COMPLY WITH PROPER INSTALLATION AND MAINTENANCE INSTRUCTIONS COULD CONTRIBUTE TO THE VALVE FAILURE.

This Hot Water Master Tempering Valves cannot be used for tempering water temperature at fixtures. Severe bodily injury (i.e., scalding or chilling) and/or death may result depending upon system water pressure changes and/or supply water temperature changes.

ASSE standard 1016, 1069 or 1070 listed devices should be used at fixtures to prevent possible injury.

These Hot Water Tempering Valves are designed to be installed at or near the boiler or water heater. They are not designed to compensate for system pressure fluctuations and should not be used where ASSE standard 1016, 1069 or 1070 devices are required. These valves should never be used to provide “anti-scald” or “anti-chill” service.

The components of the system must be of materials with a construction capable of withstanding the high limit output temperatures of the water heating source. - Watts (2013)

Other Mixing Valve Warnings - using Watts instructions as an example, include :

Need for Periodic Inspection and Yearly Maintenance: Periodic inspection and yearly maintenance by a licensed contractor is required. Corrosive water conditions, temperatures over 200°F, unauthorized adjustments or repair could render the valve ineffective for service intended.

Regular checking and cleaning of the valve’s internal components and check stops helps assure maximum life and proper product function. Frequency of cleaning and inspection depends upon local water conditions.

Building code compliance for mixing valves: You are required to consult the local building and plumbing codes prior to installation. If the information in this manual is not consistent with local building or plumbing codes, the local codes should be followed.

Inquire with governing authorities for additional local requirements. ... Valve should be installed and adjusted by a licensed contractor in accordance with local codes and ordinances. Further, this valve should be installed in a location where it is accessible for cleaning, service or adjustment. - Watts (2013)

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2022-08-15 by InspectApedia-911 (mod)

@Al,

Good work

On 2022-08-15 by Al

@InspectApedia-911, thank you, adjusted temperature all good now!

On 2022-08-14 by InspectApedia-911 (mod) - adjusting an anti-scald valve

@Al,

See our series on anti-scald valves starting at

ANTI SCALD VALVES & TEMPERATURE CONTROL / MIXING VALVES - home

and for simply adjusting the valve, I think the reason no one has bothered to make an online video is because adjusting the valve is easy.

If you don't have the instructions for your valve, download this copy

WATTS SERIES LF1170 AND LFL1170 HOT WATER TEMPERATURE CONTROL VALVES INSTALLATION INSTRUCTIONS [PDF]

or simply look at this illustration excerpted from that document

On 2022-08-13 by Al

Hi, my hot water tank uses a Watts LF1170 Series Mixing Valve, I simply cannot find any videos online how to adjust that red nob to increase the temperature, it has a mini hex wrench that I have to losen the cap but I have never done this before and I don't want to cause any leak. I would help to have a video or something showing the exact steps, thanks

On 2017-12-11 by (mod) -

Mike,

No the anti-scald valve simply mixes cold in with outgoing hot to avoid scalding temperatures. But any valve can become clogged with scale or debris, as can other pipes and heating equipment.

If both cold and hot pressure are poor the hot water system isn't the culprit.

On 2017-12-11 by mike

Hi does a anti scald valve regulate the hot water pressure in the house

On 2015-01-16 by Anonymous

Many thanks for your info. I am about track down a plumber and have them check out whats going on. I wil let you know whats what when I have some info. Thanks again for you time.

On 2015-01-15 by (mod) -

We're flying a bit blindly here Steve but it does not sound right for warm water to immediately re-heat the cold-in piping on the cold side of the tempering valve immediately after turning off the flowing hot-water.

That does suggest a failed internal check valve and possibly some back-flowing into the cold system.

If the back- flow were substantial I'd expect cold piping on the cold side of the water heater to get hot so far back into the system that warm water would come out of nearby cold faucets.

You may decide to just install a new tempering valve.

Keep us posted.

On 2015-01-15 by Steve

Just checked - the cold water inlet pipe is warm to touch down to and including where the cold water enters the system, also where the cold water enters the hot water cylinder. Yes the pipe cools immediately the hot water is turned on. It also appears to get warm immediately after turning of the hot water.

We may have discovered why our power bills are over the top. What do you think ?

On 2015-01-15 by (mod) -

No, Steve it should not. But you may just be seeing local heat transfer. How far back up the pipe do you find the cold side heating up?

Does it immediately cool down when you run hot water?

.

Does it stay cool for a time?

On 2015-01-14 by Steve

I have noticed that the cold inlet pjpe to the temper valve randomly gets quite warm . Should hot water be bypassing back down the cold water inlet ?

On 2014-03-15 by Doris Armstrong

Thank you so much, you have helped me understand the problem. Probably saved me $$ also.

On 2014-03-14 by (mod) - shouldn't I be getting more hot water, if my mixing valve isn't working properly?

No Doris - a mixing valve might fail in either mode - providing water that is too cool or water that is too hot.

Keep in mind we're only discussing water temperature, not hot water quantity - so when you say "more hot water" - more or less *quantity* of hot water is only affected indirectly by a mixing valve, in this manner:

Given a finite and limited hot water source, when a mixing valve mixes in less cold into the outgoing hot water, you'll run out of hot water sooner.

Also keep in mind that depending on the brand and model of mixing valve, the outgoing water temperature may be affected by the incoming water temperature on both the cold and hot side. If you are out of range of the incoming hot and cold temperatures - such as those shown in the table in the article above - the outgoing water temperature may be out of spec too.

On 2014-03-14 by Doris Armstrong

Thank you for your comments. To Clarify, shouldn't I be getting more hot water, if my mixing valve isn't working properly, instead of cooler water?

I have the gas on the water tank on high, the solar panels should be producing hot water also, why would I get cooler water??

On 2014-03-13 by (mod) -

Doris,

If the mixing valve no longer functions the evidence would be its inability to regulate outgoing water temperature in accordance with its setting.

Some of these products have a replaceable core that can significantly reduce the repair cost.

On 2014-03-13 by Doris Armstrong

I have been told that my Mixing Valve needs to be replaced, I have a gas water heater and solar panels also for hot water, it was installed in 2009. How can I be sure this is necessary. Five years is very little time and the expense is very large.

...

Continue reading at ANTI SCALD VALVE PROTECTION, Best Practices or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ANTI SCALD VALVES & TEMPERATURE CONTROL / MIXING VALVES - home

- ANTI_SCALD VALVES & HOT WATER QUANTITY

- ANTI-SCALD VALVE INSPECTION

- ANTI SCALD VALVE PROTECTION, Best Practices

- ANTI SCALD VALVE at TANKLESS COIL

- ANTI-SCALD WATER TEMPERATURE CONTROL TYPES

- HOT WATER ANTI-SCALD REGULATIONS

- MANUAL ANTI-SCALD TEMPERING VALVES

- POINT of USE BUILT-IN FIXTURE ANTI-SCALD VALVES

- TABLE OF SCALDING TEMPERATURES & TIMES

- WATER HEATER SAFETY

- WATER HEATER TEMPERATURE ADJUSTMENT CONTROLS

- HOT WATER QUANTITY IMPROVEMENT

- Legionella BACTERIA in WATER HEATERS

- WATER HEATER TEMPERATURE TOO COLD or TOO HOT

Suggested citation for this web page

ANTI-SCALD VALVE INSPECTION at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to WATER HEATERS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- "BDS Series Oil-Fired Hot Water Boilers, Installation Instructions, Models GS-080 -> Crown BDS-236", Crown Boiler Company, BDS 12-99, Crown Boiler Co.

P.O. Box 14818

3633 I Street

Philadelphia, PA 19134

(215) 535-8900,

Website: http://www.crownboiler.com, retrieved 2/26/2014, original source: http://www.crownboiler.com/manuals/content/ All_Models/BDS%20Series%20%28all%20models%29.pdf

The following link provides access to literature or manuals for previous Crown products:

http://www.crownboiler.com/Support/Manuals-And-Literature/Previous-Products - Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.