Dielectric Unions - Copper to Steel Pipe

Dielectric Unions - Copper to Steel Pipe

- POST a QUESTION or COMMENT about the requirement for using dielectric (dieelectric or diaelectric if misspelled) fittings when connecting copper to steel piping in buildings and the requirement for a jumper wire across dielectric fittings when grounding a plumbing system.

Dielectric plumbing connectors:

Building Code & Practical Requirements for Dielectric fittings when connecting copper to steel piping. They're not just dialectic. This article describes the building code and practical requirements for a dielectric fitting when connecting copper piping to steel pipes or steel fittings such as at the top of a water heater.

We explain the effect of galvanic corrosion at copper to steel pipe connections and we include notes on the recommendation for a jumper wire across dielectric fittings or water meteres to assure that a plumging system is properly grounded for electrical safety.

Page top illustration: dielectic unions - better replaced by a dielectric nipple as explained in this article.

The FAQs section of this article includes questions & answers about the dielectric fitting debate, concerns for fitting leakage, and notes that a brass nipple may be permitted to connect copper to steel in some building code jurisdictons.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Galvanized Steel Pipe to Copper Pipe Connections - Use a Dielectric Fitting to Avoid Corrosion

In most jurisdictions plumbing codes require the use of a dielectric fitting when joining steel piping to copper or other metals; some plumbing jurisdictions permit use of a 6-inch brass nipple in this location as an alternative to diaelectric fittings. Why?

In most jurisdictions plumbing codes require the use of a dielectric fitting when joining steel piping to copper or other metals; some plumbing jurisdictions permit use of a 6-inch brass nipple in this location as an alternative to diaelectric fittings. Why?

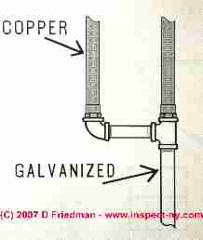

When connecting iron or galvanized iron pipes to copper in buildings, often galvanic corrosion and ultimately plumbing leaks will occur at the meeting of these two dissimilar metals.

Using a diaelectric fitting or an approved brass fitting to connect these two metals, or more commonly, using plastic or bronze fittings at the joint between these two metals will avoid future corrosion and leaks.

The photo (left) shows a galvanized iron union used to connect copper to galvanized iron. In the upper image you can just make out the black bronze ring built into this plumbing connector to avoid corrosion where the copper presses against the galvanized iron.

OPINION: in our experience having inspected thousands of homes, we find that original plumbing in older homes rarely made use of a dielectric fitting or even a brass nipple at copper to iron or steel piping - and corrosion is often found at one or several such connections.

In new construction where more careful code compliance and enforcement are applied, dielectric or brass fittings are more common. Some plumbers opine that "lined" nipples sold by some manufacturers for water heater hookup reduce the galvanic corrosion risk at those connections. - Ed.

Water chemistry affects the rate of galvanic corrosion

How do we explain that in some buildings we see direct copper-to-iron pipe connections with no corrosion? Luck? Maybe.

How do we explain that in some buildings we see direct copper-to-iron pipe connections with no corrosion? Luck? Maybe.

But the corrosivity of the water is probably a factor in how rapidly copper-to-galvanized pipe connections will corrode and leak.

Spelling note that may help some searches: it's not dialectic pipe fittings, but dielectric pipe fittings.

Teflon tape or pipe dope may slow the rate of galvanic corrosion

Another reason we may not always see rapid galvanic corrosion at copper to steel pipe connections is the use of teflon tape (or less-so, pipe dope or sealant compound) that provides a thin non-metallic contact surface between the two dissimilar metals.

Nevertheless, both to comply with plumbing codes and to avoid leaky water pipes, use an approved diaelectric coupling or an approved brass nipple (if local codes permit) when connecting copper to steel pipes or fittings or when connecting copper pipe to the steel fitting at a water heater.

More about the galvanic scale and corrosion between dissimilar metals is

at GALVANIC SCALE & METAL CORROSION.

Jumper wires are required to ground plumbing across dielectric fittings

At ELECTRICAL GROUND SYSTEM INSPECTION we discuss the need for a jumper wire around interruptions in the metal piping system, such as where a diaelect4ric fitting is installed or where a water meter interrupts continuity.

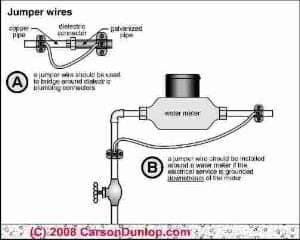

As Carson Dunlop Associates' sketch shows at (A), if the building plumbing includes dielectric fittings or non-conductive sections of piping (such as plastic piping) then the building plumbing system may not be safely grounded.

A jumper wire is installed to assure that the building metal plumbing pipes are safely grounded to earth.

The purpose of the ground jumper is to ground the building plumbing, not to use the building plumbing as a grounding system.

That is to say, we're making the plumbing safe, we're not using it to provide a ground for the electrical system.

Spelling note that may help some searches: it's not dialectic pipe fittings, but dielectric pipe fittings.

Replace Dielectric Unions with a Dielectric Nipple for Improved Leak-Resitance

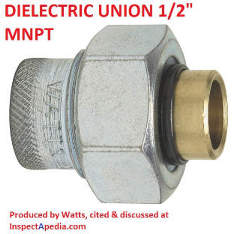

Illustration above: a dielectric union produced by Watts.

Watch out: PennState University's experts have noted, dielectric union fittings may be leak prone. Their experience is that simply tightening th union fitting is not a durable repair.

The PSU plant engineering services department recommends replacement of a dielectric union with a dielectric nipple - shown below.

Below: a 1/2" MNPT x 2-1/2" TBE Galvanized Steel Dielectric Nipple Sch 40 produced by Zoro, cited below.

Codes, History, & Manufacturers of Dielectric Unions / Fittings

- ASSE 1079

Performance Requirements for Dielectric Pipe Unions (2012), ASSE International, 18927 Hickory Creek Drive, Suite 220

Mokena, IL 60448 United States Tel: (708) 995-3019 Website: https://www.asse-plumbing.org/

Excerpt: These devices are metallic and join metallic pipe in a similar manner to standard pipe unions and flanges, with the added ability to electrically insulate one pipe section from another.

- Clearflow dielectric fittings are produced by Hartford Industries - www.hartfordindustries.com, e.g. PPP 19146P 1 Clearflow Dielectric Fitting Grooved Part Number #19146P

- Ham-Let dielectric fittings - http://www.ham-let.com

- PennState University, Dielectric Connections Dielectric Unions and Nipples - Technical Bulletin-OPP TB-232116.100 [PDF] Penn State University, Office of Physical Plant Engineering Services, University Park PA, retrieved 2020/04/30 original source: https://www.opp.psu.edu/sites/opp/files/3.pdf

Excerpts:

Whenever a ferrous metal such as black steel is connected to a non-ferrous metal such as copper, a dielectric connection must be installed to prevent galvaniccorrosion.

The installation of a fitting with inert material between the two metals prevents the flow of electrons between the metals, preventing premature failure of the piping.Traditionally, dielectric unions (see pictures at right) have been installed to perform this function. However, dielectric unions are proven sources of leaking fittings, and should be avoided.

...

Corrective action: Remove the dielectric fitting, and replace with a dielectric nipple.

- Swagelock: http://www.swagelok.com/products/fittings/dieletric-fittings.aspx

Dielectric fittings isolate monitoring instruments from the effects of electrical current. The fittings interrupt cathodic current flow while permitting full fluid flow. - Watts, Watts

815 Chestnut Street

North Andover, MA 01845-6098 USA

1-978-689-6066

(shown above is an example dielect4ric union produced by Watts, Model 3001A that connects FIP to a solder connection.

This would be a typical dielectric union whose female threaded half (bottom in the photo) is screwed to the threaded end of a galvanized iron pipe and whose copper half (upper in photo) is soldered to a copper pipe. Original source: http://www.watts.com/pages/_products_sub.asp?catId=64&parCat=77

Website excerpt:

Dielectric Unions are used in commercial and residential applications to prevent accelerated corrosion and deterioration in the piping system due to galvanic and stray current. It is installed between pipes made from dissimilar metal. - retrieved 2020/04/30 original source: https://www.watts.com/products/plumbing-flow-control-solutions/connections/dielectric-unions

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2020-04-29 - by (mod) - History of Dielectric Plumbing Unions: earliest use

Steven

Steven

Thanks for reminding me of a popular question.

History of Dielectric Plumbing Unions: earliest use

I don't know when the use of Dielectric unions first entered the model plumbing codes, and of course the adoption of those codes varies by country and jurisdiction.

But the history of the requirement for and use of dielectric unions and fittings in the U.S. dates from about 1894. I'll give some examples below.

Dielectric unions were developed for use on electric railway lines and for the underlaying of undersea cables, and at about the same time, for preventing electrolytic corrosion at the connection of water meters to building water piping.

If you'd like to get a head start on the search, besides what I will attempt, you could go to Google Scholar and take a look at the oldest patents to see the first usage.

- Lambert, Frank. WATER METER [PDF] U.S. Patent 764,603, issued July 12, 1904.

Excerpt:

… the mode of connecting water-meters or other translating device to water service-pipes, and more especially for the purpose of preventing electrolysis, which is hurtful or destructive to the meter or other translating device which may be interposed between the two ends of the service-pipe.

For the last decade this question of electrolysis has been one carefully considered by people in connection with water departments on account of its destructive eli'cct on the pipes and other translating device connected to the service-pipe, as valves, fish-traps, meters, &c.

By experiment I have found that in a meter composed of metals of different nature or even different alloys, as bronze composition and common brass, if certain parts are insulated from the other parts of the meter or the service-pipe, while the metallic parts in the meter in direct electrical connection with the pipes are badly affected by the galvanic or electrolytic action, the metallic parts which are insulated are entirely preserved from any such destructive action.

I have even found that parts made of common brass or German silver, which are very easily affected when in direct electrical connection with the pipes, are entirely preserved when all the other parts in the meter made of the same or better material after a comparatively short time are so badly oxidized that they drop down in powder.

I take advantage of this discovery to construct my meter or other translating device that can be attached to the service-pipe with means for insulating the connection between the meter and the service-pipe.

This can be done in many different ways without departing from my invention; but I have shown here in the present drawings several arrangements that can be used to reach the desired result.

- Hutton, Clyde S. "Coupling." U.S. Patent 1,071,235, issued August 26, 1913.

- McVoy, George, QUICK ATTACHABLE PIPE UNION US1308853A [PDF] patented July 8, 1919 [shown above] does not explicitly cite dielectric but is worth a look.

More examples of early dielectric unions & fittings are traced to early work on laying of undersea cables and making connections for electric railways.

- Humiston, John M., Underground-Conduit Insulation, US Patent US751985A [PDF] (name also appears as Homsron)

Excerpt:

The present invention relates to means for insulating metallic underground conduits with a view to diminish the danger of corrosion from the electrolysis by stray electric-railway currents, and has for its object to provide a simple and efficient construction and arrangement of parts wherein sections of such underground conduits are insulated one from the other in a very perfect and practical manner, all as will hereinafter more fully appear, and be more particularly pointed out in the claims. - Proudfit, Alexander C. "Coupling for electrical conduits." U.S. Patent 805,093, issued November 21, 1905.

- Downes, Louis W. "Terminal connection for electrical apparatus." U.S. Patent 1,576,102, issued March 9, 1926.

- Boyd, Albert M. "Electric insulation for metal pipes." U.S. Patent 1,592,175, issued July 13, 1926.

More-recent dielectric patents continue the history of this approach to avoiding corrosion at piping & plumbing joints

- Bradford, Randol W. "Dielectric pipe coupling for use in high temperature, corrosive environments." U.S. Patent 4,345,785, issued August 24, 1982.

On 2020-04-29 by steven - When did Dielectric unions become code

When did Dielectric unions become code

On 2020-03-26 - by (mod) -

Is an access panel required at plumbing connections, including a dielectric union, inside building cavities such as a building wall?

Thanks for the interesting questin, Jesus:

The answer is no. A diaelectric union is in a sense simply another plumbing connector like an elbow or union - those are regularly included in hidden building cavities such as walls.

From the IMC 2018 (as adapted by MO)

Section 202 General Definitions:

ACCESS (TO). That which enables a device, appliance orequipment to be reached by ready access or by a means thatfirst requires the removal or movement of a panel or similarobstruction [see also “Ready access (to)”].

READY ACCESS (TO). That which enables a device,appliance or equipment to be directly reached, withoutrequiring the removal or movement of any panel or similarobstruction [see “Access (to)”].

However access IS required to certain plumbing connections such as grease handling systems and slip joint connectors.

Example:

There are no requirements for access to bath-tub traps. Section P2704.1 requires access to all slip-joint connections for inspection and repair. Therefore, if a bathtub trap is located in a concealed space, and the trap has slip-joint connections, then some means of access must be provided. Access panels must be at least 12 inches in height and width.Slip joint connections are permitted only on traps.Bathtub traps without slip-joint connections, for ex-ample a Schedule 40 PVC trap with solvent cement-welded connections, are permitted without access. [27-3]

SECTION P270 4ACCESS TO CONNECTIONS P2704.1 General.

Slip joints shall be made with an approved elastomeric gasket and shall be installed only on the trap outlet, trap inlet and within the trap seal. Fixtures with concealed slip-joint connections shall be provided with an access panel or utility space at least 12inches (305 mm) in its smallest dimension or other approved arrangement so as to provide access to the slip connections for inspection and repair.

- 2009 IRC Plumbing / Mechanical section

On 2020-03-26 by jesuselpesado

I install a dielectric union at the water service. This installation is inside a 2x4 wall. Do I need an access panel by code?

On 2020-02- - by (mod) - A copper.jumper is ok ...

AB can you provide details? Copper wire jumper clamped between what and what? Specific product? documentation, citation?

On 2020-02-17 by ab

A copper.jumper is ok because the electric potential through the water is equally matched by the potential from the copper wire to the steel pipe. So, no current will flow. Just like two batteries placed side by side.

On 2019-10-03 - by (mod) -

Leon

Thanks for an interesting question. I don't know when dielectric fittings were first put into use but I suspect it's a long time ago as the galvanic corrosion problem was recognized in the 1980s.

If you'd like to get a head start on the search, besides what I will attempt, you could go to Google Scholar and take a look at the oldest patents to see the first usage.

On 2019-10-02 by Leon

How long have they been code?

Discussion & debate about dielectric fittings

READER OPINION: On your web page ELECTRICAL GROUND SYSTEM INSPECTION, near the bottom, is a question "jumper across dielectric fittings is asking for galvanic corrosion." Your reply to the question concludes with the comment "Also I am nor sure which jumper you saw, but connecting a ground between similar metals ought not create the concern youncite."

That same page includes an illustration [shown just above in this article - Ed] showing this very connection: copper pipe joined to galvanized pipe through a dielectric union with a jumper wire around the dielectric union.

The unilateral recommendation that this connection should be jumpered is concerning: if the union is required to protect the integrity of the pipe and whatever fluid (or gas?) flows inside it, then jumpering around the union defeats that protection and may lead to accelerated failure of the pipe. I think additional consideration on this topic is warranted. Regards, G.H. 7/10/2013

Editor's Reply:

Thank you GH for the comment, and for being interested in this episodic debate about using dielectric fittings and jumper wires around them as well as understanding the effects of galvanic corrosion.

I think we may be mixing two different concerns, so I summarize my understanding below and invite your comment if I'm mistaken.

The diaelectric union has the purpose of preventing corrosion that occurs between two dissimilar metals, such as copper pipe joined to galvanized pipe in a water supply system. In such circumstances the corrosion occurs at the point of contact between the two dissimilar metals. The diaelectric fitting includes an insulator, typically of plastic, to prevent the two metals from coming into direct contact.

A problem is that the diaelectric union may in some locations prevent the building's metal plumbing system from being safely grounded.

The jumper wire is installed to assure electrical continuity as a safety feature for the building's electrical system. E.g. if a toaster, plugged in, falls into a sink of water, a good electrical pathway between metal plumbing connected to the metal sink (or its metal components) and earth, assures that current flows to ground through that safe path, thus blowing a fuse or tripping a circuit breaker, thus protecting the building occupant from possibly fatal shock.

The ground wire connectors and ground wire do not themselves become points of corrosion in the piping system - at least not at any I've seen, most likely because the wire-to-pipe connectors use an intermediate metal, such as brass, between the copper pipe and (say) galvanized pipe.

We could and should include authoritative citations on a topic such as this - something for which we both should be alert and that I'd be pleased to add to the article.

I would add, though it's a bit too esoteric to imbed in the article, that stray electrical currents, combined with improper electrical grounding can have strange and damaging effects on a building's mechanical system.

For example, improper neutral or ground wiring at a building can cause current to flow where it is not expected, causing damage. I found costly damage to an internal refrigeration coil in a water to air cooling system was ultimately traced to improper connections in the electrical panel.

Reader Comment:

While I'm certainly not an expert on the topic, I think the assumption that galvanic corrosion will occur only at the point of contact between the two metals is flawed.

Consider for example the "lasagna cell" battery: an uncoated steel baking pan containing a lasagna (or other salty food serving as electrolyte) and covered with conventional aluminum foil. Holes will form through the aluminum foil in the places where it contacts the lasagna -- not around the edges where the foil is touching the steel.

I recently found myself in a sprinkler (irrigation) supply shop. A customer at the counter held a length of galvanized pipe with (part of) an elbow at one end. He explained that it was used in a water feature connecting underground piping to an electric pump above ground and had "rusted out" twice, each time lasting less than a year.

There was basically nothing left of the sidewall of the elbow; it had been dissolved away from the outside (I could conclude this because in one area the elbow metal was gone, exposing the threads on the end of the pipe inside it).

There's no way it could have corroded so quickly without a boost from something like galvanic corrosion. But it didn't corrode at a connection between dissimilar metals; it was the side of the elbow that was eaten out. Anyway, I think he mentioned that beyond the elbow (continuing underground) was PVC pipe so there probably was no dissimilar connection in that area at all.

In the case of the wire jumper around the dielectric union, I expect it won't help any to use a brass or bronze clamp -- both are alloys of copper and are very near copper in the anodic index (see "galvanic corrosion" page on wikipedia). For that reason I believe the corrosion will still happen.

If not so, I suppose we'd be using brass or bronze couplers or unions to join the pipes and skip the business with the plastic isolator in the dielectric union. I believe your experience (not seeing corrosion at the location of a jumper around a dielectric union) supports my suggestion that the corrosion is likely to happen somewhere out of sight -- specifically, at a point where the steel pipe contacts an electrolyte (something wet, probably soil).

I do understand (and agree with) the concern about having the plumbing systems grounded for occupant safety. To that end, I'm trying to figure out how to accomplish both mechanical and electrical protection. It seems to me that the galvanic corrosion problem occurs when copper and steel are both in an electrolyte and a conductive path exists between them -- anything that looks conceptually like a copper ground rod and a buried steel water pipe, even buried apart from each other, but with some electrical bonding between them.

Given that we're talking about a plumbing joint of copper and steel, one of these is the supply pipe buried outside and the other is the plumbing through the building interior. Suppose it's copper in the dirt and steel through the building. I guess there's no problem here (and in fact no dielectric union needed) because there's no steel immersed in electrolyte with the copper. But if it's the other way round with buried steel supply, then I think it's imperative that the steel be electrically isolated from all buried copper.

We can assume that the electrical system contains buried copper either in the form of a ground rod at the same building or at another installation nearby (and connected via the neutral wires and ground-bonding at the main service panels).

So, in this case, I think I would isolate the buried steel with a dielectric union and install a bonding wire from the copper pipe back to the electrical panel -- I wouldn't connect wire to the buried steel at all. This building would have to get its grounding some other way, maybe through ground rods, plates, etc.

As I said in the beginning, I don't claim to be an expert on the topic. I'm genuinely interested in your thoughts, and if you have electrical inspectors you consult with regularly, it'd be interesting to hear their thoughts on the matter as well.

Regarding the damage to the refrigeration coil traced back to improper connections in the electrical panel -- that sounds fascinating. If you have the time to write, I'd love to read more about the details of the problem and especially how in the world you managed to find the cause. That must have been a treat to figure out! Ugh!

Reply:

I appreciate the discussion but it seems we disagree about the locus of galvanic corrosion in plumbing systems and perhaps you didn't know that building codes require both dielectric fittings (or in some locales a brass nipple) connecting copper to steel pipes in a building as well as jumper wires around dielectric fittings when needed to assure safe electrical grounding of the plumbing system.

The jumper wire around a dielectric fitting, properly connected with approved (typically bronze) clamps to the copper and steel piping and a copper ground jumper will not itself promote corrosion at the pipe connection nor nearby.

Plumbing texts as well as field experience point out that corrosion occurs at and/or very close to (micros to millimeters) the point of contact between dissimilar metals that are further apart on the galvanic scale, such as copper and steel. Long-standing and successful plumbing practice was to connect via an intermediate metal such as brass - as the galvanic corrosion problem does not appear at, for example a copper to brass connection (there are hundreds of millions of such connections in both plumbing and heating systems today).

Diaelectric fittings, also referred to as diaelectric unions or DEUs, are required by the model plumbing codes adopted by most states and provinces, though in some U.S. states plumbing codes permit the use of brass fittings in those locations instead.

I would agree that there are episodic debates in the plumbing community about using diaelectric fittings, out of concern that some leak and others may not work as well as advertised.

Example Code Citations for the Requirement for Dielectric Connectors Between Copper & Steel Pipes

Section 316 of the California Plumbing Code is amended by adding Subsection 316.2.5 to read as follows:

316.2.5 All connections between ferrous and nonferrous pipe shall be made with a six-inch red brass nipple or a dielectric union.

Ord. 559 § 2 (part), 2010: Ord. 543 § 2 (part), 2007: Ord. 499 § 2 (part), 2002: Ord. 463 § 2 (part), 1999. Formerly 15.16.170

Other building citation code sources where the requirement for a dialectric plumbing fitting is cited:

- IAPMO: www.iapmo.org/

- New York Plumbing Code (2005)

http://www.nyc.gov/html/dob/downloads/pdf/local_law_99_05.pdf - Hawaii Plumbing Code:

http://www1.honolulu.gov/council/ocs/roh/19.pdf

On 2018-02-02 by (mod) -

Chad

If all of your water piping and connections from the copper to other fixtures or devices are copper or brass (or plastic) you're fine without adding dielectric unions.

On 2018-02-02 by Chad monty

The waterline is completely copper do you need to add dielectric unions and it’s all how far apart should they be

On 2017-12-05 by (mod) -

Use a dielectric fitting between copper an steel as described in this article, both to comply with plumbing codes and to avoid corrosion and leaks.

Depending on the corrosivity of your waterr supply stainless steel might last m longer than galvanized steel in a direct connection to copper thanks to its nickel content. But it's still steel and In a direct connection to copper will corrode.

On 2017-10-02 by Anonymous

Can you make a direct connection from copper stainless steel. Piping a water softener have a stainless control valve female threads and I wan to connect with a copper male adapter

On 2015-12-26 by (mod) -

And yes, a neutral-to-ground short could be a problem source; the electrical system, if it's not GFCI protected, won't show a thing, and everything will continue to work, but stray currents are flowing on the ground when they should all be on the neutral wire.

On 2015-12-26 by (mod) -

Joe

You make a very interesting point; I trust the long-term field observations of workers but not always the interpretation.

Grounding of plumbing is very important for safety.

But if there are stray electrical currents in the system because of other electrical errors, such as a weak short to ground or intermittent short to ground, indeed you can find corrosion or other failures. I once found a deeply-hidden stray current problem that was blamed for corrosion leaks of a heat exchanger coil on a water to air heat pump; the coil kept corroding and leaking; it was grounded; improper electrical wiring was the ultimate cause of the trouble but the problem showed up as a leak.

On 2015-12-25 by Joe D

While researching dielectric connectors and corrosion, one long time plumber that worked on a lot of vintage systems commented that systems that were grounded tended to have the most corrosion. So something is going on with all those, possibly improper grounding or neutral. If the neutral and ground are connected at the panel somehow, or a neutral wire is grounded somewhere, would that cause it?

On 2015-10-15 by (mod) -

Thank you Daniel; we agree.

On 2015-10-15 by Daniel

Barbara, yes, it's a code violation, at least here in California. I had exact same problem from hot water pipes within 3 months of changing old pipes, apparently hot water and high pressure accelerated corrosion. New plumber drove around town to find correct heavy duty fitting for copper to galvanized iron.

On 2015-06-25 by Barbara

In 2005 a construction company put in a faucet, shower combo in my tub area. they also put in copper pipping and attached them to galvanized steel without a dielectric union. So, the cold water pipe rusted, caused a water leak and a lot of damage to my house. My question: was the lack of a dielectric union to connect copper to galvanized steel a code violation in 2005, chicago, il.

thanks

Question: pinhole in copper water pipe under the slab

I have a home that is 7 yrs old in Burleson Tx. We are on a co-op water supply. I recently had a pin hole in my copper water pipe under the slap. I though it was the water but had the water dept lab test my water and all was normal. I then read about electrolysis could cause this.

I do have a ground on my water pipe and a rod out side my main. I checked whit a meter and I do have continuity between the main panel and my plumbing and my gas pipe to the hot water. can this possible cause my plumbing to fail?

The water has been ruled out so it has to be something else the pin hole was from the inside out and my house water connections are green and blue. need some help bad. I did disconnect the one ground off the plumbing when I read about the electroylis. Please advise.

Thanks

Donald McKinley 10/19/11

Reply: Causes of pinholing in copper water supply or drain piping

Donald,

With just the info in your note I can only guess at some possible causes for the pinhole leak in copper water piping under your building slab.

- the pipe could have been defective from day one

- the pipe could be a lower quality thin-walled material more vulnerable to corrosion

- the pipe could have been damaged in transport or installation or even during the slab pour

- just as you posed, on occasion a bad or improperly-connected electrical ground or another electrical problem can contribute to plumbing or other pipe corrosion at a building. I recall a ground water sourced air conditioning system that kept blowing out a very expensive cooling coil for which the problem was finally traced to just this issue.

- the water chemistry itself can be a source of metal water pipe (and even drain pipe) corrosion.

If the pH is low <6.0, the hardness low generally<50ppm, the alkalinity low generally <40ppm, the water could be considered

extremely “soft” and aggressive to the home’s metallic plumbing system. If the

chlorides are elevated >100ppm this would only compound the problem. The

water should be treated to make the water less aggressive by raising the pH, alkalinity or hardness. - CT DOH.[1]

If you do nothing but fix the pipe and the problem never recurs I'd suspect the pipe itself.

But if it were me, I'd also have a licensed electrician check that the home's grounding and neutral systems are properly wired, that the grounding electrodes are properly sized and installed, and that there are no stray currents on the neutral system nor shorts or leaks in the wiring system (an AFCI or GFCI can help detect these too).

Question: follow-up on pinhole leaks in copper piping traced to bad (grounded) neutral connections at the utility transformer

Dan, concerning the pin hole pipe leak and all the green and blue plumbing from Oct. 19 & 21, 2011. I have seen this before and traced it to bad grounded (neutral) connections at the utility transformers or tap boxes causing all the neutral loads to be carried on the grounding system such as the copper plumbing.

I even seen it in one house but show the signs of trouble in a neighbors house because of a common city water pipe. This situation eats the copper water piping from the inside out and can cause green/blue water color, usually the first sign.

Also, these pin hole can develop because of excessive flux being used before sweating. The excess flux lays in the bottom of the pipe and corrodes the copper, hence pin holes on the bottom only. - Rod, electrical contractor, 8/1/12

Reply:

Rod,

thanks for the important and helpful comment - we agree completely. Bad electrical grounding and incorrect connections among grounding connections can cause a wide range of odd problems, including corrosion and leaks in plumbing, HVAC equipment, even equipment internal parts such as the coil in a water to air heat exchanger coil in a groundwater sourced heat pump.

The excessive solder flux corrosion problem is not one I'd realized -thanks for that tip. I suppose we could confirm that problem cause after the fact by noticing just where the copper piping leaks are occurring - all at solder joints - and then disassembling or cutting one of those joints apart to inspect the interior of the pipe. Water chemistry may also play a part in that corrosion problem.

Thanks again. Astute and helpful. If you want us to cite and refer readers to you in your area email me contact information.

Daniel

Question: jumper across dielectric fittings is asking for galvanic corrosion

You show a jumper wire across a dielectric plumbing connection (between copper & galvanized pipe). This will promote galvanic corrosion & make the dielectric connection pointless. Instead of at the connection the corrosion will now take place inside the galvanized pipe near the jumper wire clamp.

Grounding the plumbing does not make a house safer. It places half an electrical circuit through out the house. This increases the likelihood of connecting that circuit with some current. - Galvanic 9/20/12

Reply:

Galvanic,

The jumper wire across a dielectric fitting does not cause corrosion in copper to steel piping connections provided it is properly made using approved connectors (typically brass or bronze clamps).

If we don't jump across a non-conductive dielectric fitting on water piping then the water piping is not grounded. By current NEC, metal piping may not be used as a grounding conductor, but metal water piping in contact with the earth for a length of ten feet or more, that piping is indeed connected to the electrical ground system.

For protection from lightning and possibly leakage from a high voltage transformer, the current National Electrical Code (NEC) requires two grounding electrodes at a building. If one of these is water piping it is tested and must show less than 25 ohms of resistance to earth.

NEC Electrical Code Citations on grounding water piping

- NEC 250.50 "All grounding electrodes as described in 250.52(A)(1) through (A)(6) that are present at each building or structure shall be bonded together to form the grounding electrode system."

- 250.52(A)(1) Metal Underground Water Pipe - any connection to the water pipe must be within 5 feet of it entering the structure

- 250.52(A)(1) Water pipe electrode to be supplemented by another type of electrode (2) through (6) [listed just below]

- 250.52(A)(2) Metal Frame of Building or Structure grounding requirements

- 250.52(A)(3) Concrete-Encased Grounding Electrode

- 250.52(A)(4) Ground Ring requirements

- 250.52(A)(5) Rod and Pipe Grounding Electrodes

- 250.52(A)(6) Plate Electrodes (7)(B): Gas lines and aluminum electrodes are not permitted

- 250.53(D)(2) Supplemental Grounding Electrode Required,

Typically, pinholing in copper piping that is traced to an electrical grounding problem (electrolysis) is, if we exclude neutral/ground wiring errors, traced to inadequate local grounding electrodes.

Thanks for the interesting comment. I'm not sure where your surmise takes us, since there are both code and basic safety reasons for grounding house plumbing. Also I am nor sure which jumper you saw, but connecting a ground between similar metals ought not create the concern youncite. Can you give us a citation or article to review?

We ground building water piping for electrical safety for the occupants, not to provide an additional electrical ground path

The reason people ground in-building plumbing is not to provide an additional grounding conductor in a building but to ground the plumbing. Picture someone knocking a toaster into a stainless steel sink or into any sink with a metal drain and drain piping.

If the sink and piping are grounded the fuse or breaker will blow. If not, the system is waiting to electrocute the building occupant when s/he touches the live water/toaster in the sink and perhaps a nearby metal faucet, radiator, or other component that is ultimately connected to earth.

Incidentally, as we discuss pinholing and bad neutral connections, keep in mind that the return path for current in a building's electrical system is not intended to be primarily through the building's local grounding electrodes. Rather it is on the neutral wire that is connected back to the pole transformer.

See LOST NEUTRAL SHOCKS HOMEOWNER for details of what can happen when this connection is not made or goes bad.

Question: electrolysis corrosion problems after a ground system change

(Aug 24, 2014) Eric Schemanske said:

My water supply from the city comes in through the basement. Some years back the city installed a new meter in close proximity to where the pipe comes through the basement wall, which is copper (one inch). They connected a electrical ground from the one side of the meter ( copper pipe) to where the pipe enters through the wall.

Now I have electroylis ( corrosion, big time) after

several years. The clamp they used appears not to be (?) compatible with code to prevent this from perhaps happening. Is this possible?

Sincerely,

Eric

Reply:

Eric

If the installer used a listed grounding system bonding clamp then its composition was intended to avoid corrosion due to electrolysis.

Usually the installer also includes a jumper around the water meter to assure continuity of grounding of the piping system.

I would be looking for a different electrical problem first as ruling it out is important. There may be stray voltage on your electrical system's neutral circuit or ground circuit from a short somewhere in the electrical panel or building wiring.

Question:

(Oct 28, 2014) Jason said:

Is there a need to provide a dielectric fitting in a steam system where steel piping connect to copper piping?

Is there any problem with galvanic corrosion at that point?

We have a situation where steel piping is being connected to a copper tube heating coil both on the steam supply and condensate return without any dielectric isolation.

Reply:

Lucky, but still it'd have been good practice; steam condensate is in fact quite corrosive.

Question:

28 Feb 2015 Anonymous said:

can we connect bronze to steel without die electric union

Reply:

Take a look at GALVANIC SCALE & METAL CORROSION for a clear explanation of this.

...

Continue reading at GALVANIC SCALE & METAL CORROSION or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- BUILDING CODE DOWNLOADS - free downloadable PDF files of building codes & standards

- CORROSION & MOISTURE SOURCES in PANELS

- ELECTRICAL GROUND PIPE CORROSION

- GALVANIC SCALE & METAL CORROSION

- GALVANIZED STEEL WATER PIPING

Suggested citation for this web page

DIELECTRIC FITTING CODES at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to PLUMBING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com 11/06

- Roger Hankey is principal of Hankey and Brown Inspections, Winter Park, CO. Mr. Hankey is a past chairman of the ASHI Standards Committee and served in other ASHI chapter and national leadership roles. Mr. Hankey is a National Radon Proficiency Program certified measurement professional and a Level II infrared thermographer. Contact Roger Hankey at: 970-393-6604 - rogerhankey47@gmail.com . Website: www.HankeyandBrown.com Mr. Hankey is a frequent contributor to InspectAPedia.com.

- "The Fight Against Corrosion - A Study of the Nature of Corrosion and its Problems in Water Services and Heating Systems", Daniel Davies, Research and Development Services, Stansted Mountfichet, Essex, England, World Plumbing Conference-IV, "Plumbing and the World Environment, Compendium of Workshop Papers, October 3-6, 1996, Hyatt Regency Chicago, Chicago, IL", [personal correspondence, DJF - Author, July 2011]

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.