PB Pipe, Polybutylene Pipe in Buildings

PB Pipe, Polybutylene Pipe in Buildings

Properties, uses, standards, defects, failure claims, class action + Polybutene (PB-1) Piping Information

- POST a QUESTION or COMMENT about PB or polybutylene plastic piping in buildings: installation, inspection, cracks, failures, leaks, hazards

PB polubutylene plastic plumbing pipes:

This article describes the properties of polubutylene (PB) plastic piping and tubing used in buildings.

We include information about failures and problems with some generations of plastic pipes (PB or polybutylene) and we describe good building practice installation details where plastic piping is being installed.

The articles at this website will answer most questions about plastic building water supply and building drain piping products, failures, and claims as well as many other building plumbing system inspection or defect topics.

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

PB Pipe: Polybutylene Plumbing Plastic Pipe Use, Installation Specs, Failures, Leaks, Claims, Settlements

Thumbnail: Polybutylene (Polybutylene) Plumbing (plastic pipes): gray plastic water supply piping cracked, leaked, and resulted in a class action and settlement.

PB or Polybutylene pipe material (photo at left, center horizontal piping) is gray plastic water supply piping that racked, leaked, and its early use resulted in a class action and settlement.

In 1995 a $950 million class action settlement, Cox v. Shell Oil Company, provided relief for damage due to leaks in Polybutylene plumbing (PB Plumbing) within certain age constraints. Periodic notices were to be provided to homeowners over a 12-year period (ending ca. 2007) as follows:

Owners who purchased a house, mobile home, or other structure in the United States after August 21, 1995, provided that the structure contained polybutylene piping with plastic or metal insert fittings when they purchased it, are included in the class. These individuals may have been entitled to free replacement of their plumbing if it leaked previously or in the future.

The Polybutylene Pipe Settlement case is now closed. Homeowners whose structures still contain problematic versions of PB plumbing may nevertheless find that their building or mobile home is damaged by leaks and needs repairs. However there is no longer relief provided under the class action suit.

By 2010 it would be uncommon to find problematic plastic piping in buildings as we expect that where leaks were a problem, they have in many if not most installations, been discovered and repaired by now.

However home inspectors and home buyers as well as building maintenance staff need to be alert for discovery of older problematic or leaky plastic piping in buildings.

When we see several types (colors) of plastic piping mixed together, especially on older renovation or handyman plumbing jobs we worry that amateur work may have omitted use of the proper pipe glues and sealants.

But the majority of leak problems with polybutylene supply lines involve failure of plastic fittings. Fitting failure may lead to the need for system replacement.

This type of fitting was commonly used from the late 1970s until the late 1980s. Copper fittings were used in most installations from the late 1980s until the late 1990s. Failure of copper fittings is rare. Failure of the actual polybutylene piping also seems relatively uncommon.

For at least some of the extensive plastic pipe failure claims, an important factor in the PBS pipe failure mechanism included water that contained significant levels of chlorine.

See CHLORINE SOURCES in DRINKING WATER for related information.

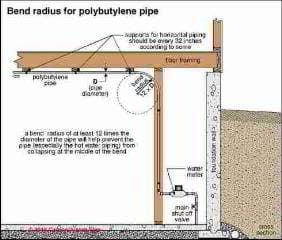

Connections for PB or polybutylene water piping can be made without soldering, and the pipe is easy to work with, as Carson Dunlop's illustration (left) shows.

Our photo (below right) shows hot and cold water piping using these materials and fittings in a new building.

Polybutylene Piping failures

Polybutylene piping has been (PB) the source of considerable controversy due to failed fittings, especially first generation plastic fittings.- Home Reference Book, used with permission.

In this article (below) we include links to information about PB piping failures, claims, and litigation. -DF

Identification Photographs of PB (Polybutylene) Pipe & Piping Failures

Here are some better images from yesterdays inspection, this is a good article but has poor images of in the field PB in my opinion.

Here are some better images from yesterdays inspection, this is a good article but has poor images of in the field PB in my opinion.

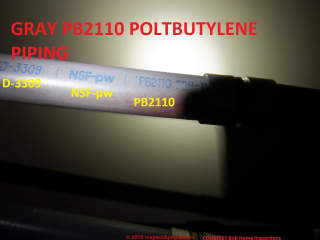

Photo:, Gray PB2110 PB (polybutylene) piping identifiied at a home inspection, photo courtesy of BnB Home Inspections

[Click to enlarge any image]

Reply:

BnB:

Thank you for the photo contributions; I'll add these PB identification photos and your comments in the article above.

Your photos include a mix of black ABS (DWV pipe), gray PB (Polybutylene) piping identified in your thoughtful photo showing pipe PB2110 markings (manufactured ca 1978-1995), and what looks like red and blue PEX (Cross-Linked Polyethylene) piping.

Above

Special thanks to Brad Barbour, BNB Home Inspection Services, for clarifying that the "red" plastic pipe shown in his photographs is ALL polybutylene or PB pipe; the "red" pipes had been painted red, most likely to identify hot water lines.

Identifying bad PB piping such as PB2110 by color can be further misleading as that polybutylene piping was produced in both gray and dull or off-white colors. There are other gray or white "plastic" piping materials that are not PB, such as gray or even white PEX.

I also see what looks like gray PB fittings (similar to Zurn PB fittings / connectors but probably a different brand) and plastic gray PB shutoff valve - leaking nicely;

Below: corroded, leaky clamp fittings on the PB pipe installed in this same home. Again at right you can see the red-stripe painted on gray PB pipe carrying hot water.

Below:

Some of the identification markings on this Gray PB or Polybutylene plastic pipe showing the Vanguard® brand. This polytbutylene is PB2110.

These PB2110 polytbutylene pipe photos showing both gray PB pipe and red-painted gray PB pipe as well as some ABS drains were provided by Washington State home inspector Brad Barbour whose contact data we give below. Mr. Barbour notes that

These photos were taken from a 1989 Manufactured home. I saw The Vanguard markings on the piping as well, but this was not a Vanguard Manabloc set-up, [Photo below].

[Click to enlarge any image]

- Brad Barbour, BNB Home Inspection Services, Residential Home Inspector Wa. Lic. #1226, Structural Pest Inspector W.S.D.A. Lic. #87852, International Assoc. of Home Inspectors-- Certified Inspector #15011605, Website: bnbhomeinspections.com Tel: (360) 724-8180 - Whatcom, Skagit, Island & Northern Snohomish Counties in Washington State

Watch out: when relying on the color of plastic pipe to identify its type. Identifying PB pipe, PEX, or other plastic pipes by depending on color (red or blue) can trick us.

Pipe may have been painted; some of the PB pipe in Barbour's photos had been painted red. Click to enlarge those images and you can see the peeling red paint and the gray PB plastic below.

Similarly, we may also encounter gray PEX water supply piping, for example the Zurn PEX Non-Barrier Tubing & Zurn Q3PC100X shown below.

Above: this tubing is PEX not Polybutylene. Most plastic piping products are stamped with the piping type, the manufacturer, and other information.

ABS pipes are discussed at ABS PLASTIC PIPE

PEX piping is discussed separately at PEX PIPING INFORMATION

PB Pipe: Polybutylene Pipe Failures, Claims, Litigation, Contact Information (now obsolete)

Our photograph of a broken white Schedule 40 PVC sewer line in a crawl area (left) illustrates what can happen to this material if a sewer line is blocked and exposed to freezing.

Our photograph of a broken white Schedule 40 PVC sewer line in a crawl area (left) illustrates what can happen to this material if a sewer line is blocked and exposed to freezing.

Case Law Citation for Polybutylene Piping Failures

Tina Cox et. al., Plaintiffs vs. Shell Oil Company, et. ano., Defendants, Civil Action 18,844, Notice of Class Action and Settlement, in the Chancery Court for Obion County Tennessee, at Union City, Tennessee, settlement approved on November 17, 1995. The class included all owners and past owners of structures ... with a certain type of plumbing ...

- PB (polybutylene with mechanical fittings) Piping leaks: especially in mobile homes and in the U.S. South, for example trailers and double-wides throughout Florida that were piped with this material - per M Cramer.

See "Polybutylene Piping: Time Bomb?" Daniel Friedman, Journal of Light Construction, August 1996 [Technical Q&A]. - Plastic Supply and Drain Piping Failures: leaks, lawsuits, settlements are also listed atReferences or Citations

- If plastic water piping is installed, such as polybutylene water supply piping, it should be at least 18" from the water heater.

- New mobile home and trailer units: 3/4" supply piping, must be installed a minimum of 6" off the ground; a shutoff valve is required. Also

see WATER SHUTOFF VALVE LOCATION, USE where to find and how to turn off the main water valve in buildings

Watch out: as of December 2016, all of the PB pipe class action, claims, litigation, and settlement websites, links, and claims administrators listed below had been removed from internet access and the links return either a 404 not-found error message or they link to plumbing contractors who purchased the links to obtain business.

Below we include excerpts from original polybutylene piping class action settlement claims data and we show the original links and sources for historic reasons even though, as we indicate, those web page links no longer produce useful content.

These images included a claim eligibility form showing that the claims were to be mailed to the Consumer Plumbing Recovery Center, CPRC, POB 969006, Plano TX 75086 Tel: 800 392 7591.

To the best of our knowledge as of 12/17/2016, of the images were published by that claims settlement agency - last updated on 3/8/1996 and now defunct.

Watch out: all of the PB piping class action lawsuit settlement links are dead - Editor.

- PLUMBING FAILURES: SPENCER Class settlement. 10% of replacement cost/damages, only for acetal (plastic)fittings Polybutylene. Original link no longer working: http://www.spencerclass.com returns "

The Spencer Class website has been closed" - Polybutylene Plumbing Failures, had detailed information, no longer a working web page: http://www.plumbing911.com/poly/index.html

Polubutylene pipe settlement fund (now closed to new claims) was at: info@pbpipe.com\ or http://www.pbpipe.com/

- Polybutylene plumbing info at U. Arizona Polybutylene (link now closed: http://ag.arizona.edu/AZWATER/awr/nov94/leaks.html ) piping lawsuit settlement website (link now closed: http://www.csusm.edu/public/ita/homeowner/resource/polypipe.htm) Polybutylene plumbing lawsuit (link now closed http://www.hunt.com/polybutylene/pipe/propset.htm)

Recommendations (Specifications) for PB Polybutylene Water Pipe Installation

Industry associations, including the Polybutylene Product Line Committee of the Plastic Pipe & Fittings Association have made recommendations for successful installation of polybutylene piping systems, including those listed below.

Frankly by 2010 we were never seeing PB installations in buildings at which all of the recommendations below were followed and OPINION it may be that industry experts no longer consider all of the 1990 recommendations necessary.

- Piping shall comply with ASTM D 3309 (gray piping) Hot and Cold;

- Stored PB piping may be loosely coiled or bundled but should not be taped

- Use annealed copper crimp rings (note this may have changed since 1990)

- Use copper or brass insert fittings

- Compression fittings are permitted if of a type recommended for PB

- Manifold connections (such as for radiant heating) must be of a type recommended for PB

- PB piping should be free of cuts, gouges, or deep scratches, tar, kinks, grease, soldering flux, and should not be faded or discolored

- PB piping end cuts should be square and free of burs (use an approved PB pipe cutting tool)

- PB pipe crimp rings should be 1/8" to 1/4" from the end of the tubing and do not use multiple crimp rings at an individual fitting connection

- PB Crimp rings shall be perpendicular to the centerline of the pipe or tubing (not askew)

- Each PB crimp connection should be checked with a GO-NOGO gauge and any fitting that does not pass should be cut out and replaced.

- In making a run of PB piping allow 1/8" of slack per 12" of run

- The radius of a PB pipe bend should be 12 x the tubing diameter (or more).

- Protective sleeves or bushings should be installed at the beginning and end of straight runs of PB piping when penetrating studs

- Supports for PB piping shall be used at significant changes in direction

- Horizontal support for PB piping should be 32" o.c. for pipes from 3/8" to 3/4" diameter, and at 48" o.c. for pipes from 1" to 1 1/2" in diameter.

- Vertical pipes should be supported at every floor and at the mid-point between floors for pipes smaller than 1" in diameter

- Piping supports should not restrict the horizontal movement of piping

- With PB pipe use only hangers or supports recommended specifically for PB pipes

- Do not connect a hose bib directly to PB piping. Use anchored metal pipe for this transition to avoid strain on the PB pipe

- Transitions should be made with fittings approved for that use

- Keep PB piping at least 6" horizontally and 12" vertically from high heat sources such as heating flues or heating pipes

- Do not use PB piping in recirculating hot water plumbing loops; keep PB piping branch lines at least 36" off of recirculating hot water pipe loops; Hot water heater connections should be at least 18" away from the water heater (and separated by metal piping); do not install PB piping downstream from a demand-type or instant or "tankless" hot water heater.

- Test pressure for PB piping systems should be at least equal to normal system working pressure but also must be not less than 40psi nor more than 225 psi. NOTE that some plastic piping is marked with other maximum pressure ratings that must be respected when testing too.

- Pressure test piping for at least 15 minutes. Note that a light pressure drop in two hours is normal (due to slight expansion of the piping, not due to leaks).

PB Polybutylene & Polybutene (PB-1) Piping Installation, Standards, Guides

Illustration: modern or contemporary Polybutene piping, described by the PBPSA cited below.

Note: Polybutene is often referred to as Polybutene-1, Polybutylene, PB-1 or PB.

Polybutene is not sold by PBPSA members for use in pipe applications intended for use in North America, and those parties require their customers or distributors not to sell products made from Polybutene into pipe applications for North America. - PBPSA cited below.

- Buteline, POLYBUTYLENE PIPING PB WORKING PRESSURES [PDF] Buteline Plumbing System, Buteline NZ Ltd 29 Lady Ruby Drive, East Tamaki, Auckland, New Zealand PO Box 204308, Highbrook, Auckland 2161, New Zealand Freecall: 0800 BUTELINE P: +64 9 273 5800 F: +64 9 273 5808 Facebook: ButelinePlumbingSystemsNZ - retrieved 2022/07/30, original source: https://www.buteline.com/nz/nz/buteline/technical-information/working-pressure

- Buteline, POLYBUTENE-1 (PB-1) PIPING INFORMATION [PDF] Buteline, Op. CIt. - retrieved 2022/07/30, original source: https://www.buteline.com/nz/buteline/technical-information/polybutene-1-pb-1

Excerpt:

Polybutene-1 was developed over 30 years ago specifically for use as a hot and cold water plumbing pipe material.

PB-1 resins are flexible, linear polyolefins produced from 1-butene as homopolymers and as copolymers with ethylene. Polybutene-1 is a proven solution for the conveyance of clean healthy drinking water.

The most important commercial application for Polybutene-1 (PB-1) is therefore in plumbing pipe for residential and commercial use.

With superior temperature and thermal capabilities compared to other materials, it endures and continues to perform both in low and high temperature applications.

The flexibility of Polybutene-1 pipe assists installers and eliminates water hammer noise. Polybutene-1 is also environmentally friendly as it is 100% recyclable. - iPlex, Pro-Fit POLYBUTYLENE PLUMBING SYSTEM INSTALLATION GUIDELINES [PDF] IPLEX Pipelines Australia Pty Limited. ABN 56 079 613 308

Ph: 13 18 40 or Fax 13 18 60

www.iplexpipelines.com.au - retrieved 2022/07/30 original source: https://www.iplex.com.au/assets/Uploads/934dea846e/Profit-Polybutylene-Technical-Guide.pdf

Excerpt:

This technical manual details features and installation aspects of the three ranges of IPLEX Pro-fit® Polybutylene (PB) pipes and fittings system: IPLEX Pro-fit® PB Hot and Cold Water – Grey Pipe IPLEX Pro-fit® PB Recycled Water – Purple Pipe Fittings and tools for all three pipe systems are identical.

The IPLEX Pro-fit® system meets the equirements of Australian Standard AS/NZS 2642 Parts 2 & 3. The system is intended for use by licensed plumbing tradesmen who are used to working in accordance with accepted plumbing practice and the Australian/New Zealand National Plumbing and Drainage Standard AS/NZS 3500. - NSFI, POLYBUTYLENE (PB) PLASTIC METER PIT TUBING [PDF] (2016) National Small Flows International, Special Engineered Specification NSF SE-8200, Website: https://info.nsf.org/Certified/SELNK/8200.pdf

Excerpt:

Polybutylene (PB) tubing is used in belowground meter pit installations because its flexibility offers easy access to the meter for maintenance and readability. Polybutylene tubing used for this purpose was previously tested under the specifications of ASTM D2666, which was withdrawn from ASTM in 2005.

- PBSA, PB-1 POLYBUTENE PIPE PERFORMANCE [PDF] PBSA, Polybutene Piping Systems Association, Email: pbpsa@posteo.de Website: pbpsa.com - retrieved 2022/07/30, original source: https://www.pbpsa.com/pipe-performance

Contact offices in Switzerland, The Netherlands, The UK, Spain

Watch out: Excerpt:

Polybutene is often referred to as Polybutene-1, Polybutylene, PB-1 or PB. Polybutene is not sold by PBPSA members for use in pipe applications intended for use in North America, and those parties require their customers or distributors not to sell products made from Polybutene into pipe applications for North America. - PBSA, PB-1 PIPING SYSTEM INSTALLATION & JOINTING [PDF] - retrieved 2022/07/30, original source: pbpsa.com/installation-jointing

- PBSA, POLYBUTENE-1 COMPARED TO PE-RT & PEX [PDF] PBSA, Op. Cit., - retrieved 2022/07/30, original source: https://www.pbpsa.com/uploads/files/resources/pbpsa-pb1-pert-pex-en.pdf

- PBPSA, A REVIEW OF THE PERFORMANCE OF POLYBUTENE PRESSURE PIPING

SYSTEMS [PDF] PBSA, Polybutene Piping Systems Association, Email: pbpsa@posteo.de Website: pbpsa.com - retrieved 2022/07/30, original source: https://www.pbpsa.com/uploads/files/resources/pbpsa-brochure-en.pdf

Excerpt:

Polybutene (also named Polybutylene) was discovered over 50 years ago. Its introduction into pressure piping applications started in the mid 1960s. Since then continuous research and development has resulted in optimised material characteristics, improved manufacturing technology and sophisticated designs of piping systems components. - Nueva-Terrain SDP POLYBUTYLENE TECHNICAL MANUAL [PDF] (2014) Nueva Terrain S.L., Pol. Ind. Jundiz

C/ Paduleta nº 2

01015 VITORIA - ÁLAVA (ESPAÑA)

Tel. 945 14 11 88 - Fax 945 14 33 36

E-mail: nuevaterrain@nuevaterrain.com

http://www.nuevaterrain.com - retrieved 2022/07/30, original source: https://www.pbpsa.com/uploads/files/resources/nueva-terrain-technical-manual-2014-1-en.pdf

Excerpt:

The purpose of this technical manual is to provide an objective and scientific justification of the technical characteristics of the SDP Terrain Polybutylene piping systems for hot and cold water supply, as well as their use in these installations. ... what we are hoping to do is offer a clear explanation of our piping systems and show the reader their differences and advantages compared to other systems and materials.

The different qualities and advantages of plastic compared to metal systems are widely known and accepted. However, this is not the case between the newer products within this market.

It is common to find a wide range of piping systems on the market that fall under the same umbrella term or definition of plastic piping, but, as we will see below, their characteristics and features are completely different.

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2023-07-22 by InspectApedia Publisher - could old piping stock be used after discontinuation date

@Chris B,

We can't be certain without seeing any identifying markings on your drain trap parts but I wouldn't rule out that a builder used old stock made before 1996 in a home built in 1996.

That doesn't look like a high-risk part nor location - any leaks would be quite visible. In any event if that's the only plastic drain pipe that raises a concern, it's happily in a location that makes it easy and inexpensive to simply replace the part.

A complete pop up sink strainer assembly in chromed brass costs less than $25. as illustrated by these parts from Canadian Tire.

See details at

PB POLYBUTYLENE (PB) PIPES - you are on this page

PB PIPE FAILURE CLAIMS

and don't hesitate to post photos of any markings on your piping or to add follow-up thoughts or questions.

[Ed. note: this question was originally posted on our home page and moved to this relevant topic page.]

On 2023-07-21 by Chris B

My home was built in 1996. Does it have grey PVC, or poly B? It was an entire neighborhood, if poly b was banned in 95 would our town allow this?

...

Continue reading at PLASTIC PIPING ABS CPVC PB PEX PPR PVC - topic home, or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- CHLORINE SOURCES in DRINKING WATER

- PIPING in BUILDINGS, CLOGS, LEAKS, TYPES - home

- PLASTIC PIPE LEAK CAUSES

- PLASTIC PIPING ABS CPVC PB PEX PPR PVC - home

- ABS PLASTIC PIPE

- CPVC & PVC PLASTIC PIPING

- JM Eagle® DEFECTIVE PVC PolyVinyl Chloride PIPING LAWSUIT

- Kitek® PLASTIC PIPELEAKS & LAWSUIT

- PB POLYBUTYLENE (PB) PIPES

- PB PIPE FAILURE CLAIMS

- PEX PIPING INFORMATION

- PEX vs. COPPER PIPING, SAFETY

- PEX BRASS CONNECTOR LEAKS

- PEX CONNECTIONS to WATER HEATERS

- PLASTIC PIPE LEAK CAUSES

- PLASTIC vs. COPPER PIPES in BUILDINGS

- PPR PIPING GUIDE

- PVC & CPVC PIPE INSTALLATION STEPS

- PVC & CPVC PIPE GLUING SET & CURE TIMES

- PLASTIC PIPE PRESSURE LIMITS

- PLASTIC PLEXVENT ULTRAVENT RECALL

Suggested citation for this web page

PB POLYBUTYLENE (PB) PIPE at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to PLUMBING SYSTEMS

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- Eric Galow, Galow Homes, Lagrangeville, NY. Mr. Galow can be reached by email: ericgalow@gmail.com or by telephone: 914-474-6613. Mr. Galow specializes in residential construction including both new homes and repairs, renovations, and additions.

- Mark Cramer Inspection Services Mark Cramer, Tampa Florida, Mr. Cramer is a past president of ASHI, the American Society of Home Inspectors and is a Florida home inspector and home inspection educator. Mr. Cramer serves on the ASHI Home Inspection Standards. Contact Mark Cramer at: 727-595-4211 mark@BestTampaInspector.com

- John Cranor [Website: /www.house-whisperer.com ] is an ASHI member and a home inspector (The House Whisperer) is located in Glen Allen, VA 23060. He is also a contributor to InspectApedia.com in several technical areas such as plumbing and appliances (dryer vents). Contact Mr. Cranor at 804-873-8534 or by Email: johncranor@verizon.net

- [3] PB (polybutylene with mechanical fittings) Piping leaks: especially in mobile homes and in the U.S. South, for example trailers and double-wides throughout Florida that were piped with this material - per M Cramer. See "Polybutylene Piping: Time Bomb?" Daniel Friedman, Journal of Light Construction, August 1996 [Technical Q&A].

- [4] ABS Plastic Pipe: "All Black -hit," defective black ABS plastic waste pipe manufactured in the mid 1980's failed by cracking. Additional information: www.abspipes.com

- [5] Polybutylene Plumbing (plastic pipes): gray plastic water supply piping cracked, leaked, and resulted in a class action and settlement.

- [6] ABS Plastic Drain/Waste/Vent (DWV) pipe failures: reported for Centaur, Phoenix, Polaris, Gable, and Spartan pipe mfgs. for pipe made between 1985 and 1988. CPSC Hot Line: 800-638-8270 or ABS Drain Leaks/Failures-Class Action Settlement COX settlement through Shell Oil set up by a contractor involved in the settlement Plumbing Failures: Spencer Class settlement. 10% of replacement cost/damages, only for acetal (plastic)fittings Polybutylene plumbing lawsuit proposed settlement-old site

- COX settlement through Shell Oil set up by a contractor involved in the settlement

- Additional information: ABS PLASTIC PIPE FAILURES

- Eric Galow, Galow Homes, Lagrangeville, NY. Mr. Galow can be reached by email: ericgalow@gmail.com or by telephone: 914-474-6613. Mr. Galow specializes in residential construction including both new homes and repairs, renovations, and additions.

- [7] PB Technology Center (information about PB Pipes) Tel: 800-338-7732, also see the 1990 PB Pipe recommendations published by the Polybutylene Product Line Committee of the Plastic Pipe and Fittings Association.

- Polybutylene Plumbing Failures: Spencer Class settlement, Web: spencerclass.com, 10% of replacement cost/damages, only for acetal (plastic)fittings

- [8] Polybutylene plumbing info at U. Arizona

- [9] Polybutylene piping lawsuit settlement website

- [10] Polybutylene plumbing lawsuit proposed settlement-old site

- [11] plumbing911.com/poly/ Polybutylene Plumbing Failures , Lots of Info about, but slow-loading busy site - appears dead 2024/01/24

- [12] Zurn Manufacturing, Web: zurn.com , Zurn Pex, Inc., Highway 11 East, Commerce, TX 75428, Tel: (903) 886-2580

provides information about installing and using PEX piping including Type b PEX through their website. Quoting from the company's website

Zurn was founded in 1900 in Erie, PA. It originally manufactured a patented backwater valve, and it now manufactures and distributes one of the largest plumbing products packages in the world! Zurn includes: the Specification Drainage Operation, AquaFlush flush valves, AquaSense sensor-operated plumbing products, AquaSpec commercial faucets, Wilkins, Zurn Light Commercial, Flo-Thru, the Chemical Drainage Systems, Zurn PEX Plumbing Systems and Zurn Radiant Heat. - [13] Zurn PEX PLUMBING DESIGN AND APPLICATION GUIDE [PDF] - web search 2023/04/06 & 12/23/2010, original source zurn.com/operations/pexrh/pdfs/installation/PEXDesApplGuide.pdf

- [14] Zurn Pex Plumbing

Products Liability Litigation, United States Court of Appeals

FOR THE EIGHTH CIRCUIT, No. 10-2267, Filed 6 July 2011, Quoting:

Minnesota homeowners brought this action1 against Zurn Pex, Inc. and Zurn Industries, Inc (Zurn) alleging that brass fittings used in the company's cross linked polyethylene (PEX) plumbing systems are inherently defective. In pretrial motions the homeowners sought class certification for their consumer protection, warranty, and negligence claims, and Zurn moved to strike the testimony of two of the homeowners’ experts. After denying Zurn's motion to strike the expert testimony, the district court2 granted the homeowner requests for class certification for their warranty and negligence claims, but denied it for their consumer protection claims. Zurn appeals from the district court's certification order. We affirm.

Web search 4/12/12, original source: www.ca8.uscourts.gov/opndir/11/07/102267P.pdf - [15] Uponor, Inc., F1807 Plumbing Court File No. - United States District Court, District of Minnesota, In Re: Uponor, Inc., F1807 Plumbing Court File No. 11-MD-2247 ADM/JJK

Fittings Products Liability Litigation, "

Order Granting Motion to Certify Class for Settlement Purposes and for Preliminary Approval of Class Action Settlement and Form and Dissemination of Notice to the Class" Quoting:

The Motion for Preliminary Approval of Class Action Settlement was heard on January 12, 2012. After review of pleadings and briefing, and having heard the arguments of counsel for good cause shown, it is hereby ORDERED that: (1) the Motion for Preliminary Approval of Nationwide Class Action Settlement Agreement; (2) preliminary and conditional certification of a settlement class; (3) approval of the form and content of Notice and Settlement; (4) an injunction and stay of all claims and actions against the RTI Defendants

Web search 4/12/12, original source: http://www.mnd.uscourts.gov/MDL-Uponor/ - [16] Bonnie Ransom Stern & Gustavo Lagos, "Are There Health Risks from the Migration of Chemical Substances from Plastic Pipes into Drinking Water? A Review", Human and Ecological Risk Assessment: An International Journal

Volume 14, Issue 4, 2008, Abstract:

Plastic pipes used to convey hot and cold drinking water are synthetic polymers containing numerous additives that enhance durability, impact strength, and toughness, and resist material degradation. Although some research studies have been conducted to evaluate the type and levels of chemical substances migrating from polymeric materials into drinking water, the potential adverse health effects associated with these compounds in potable water have not been described. This review evaluates the literature on the occurrence of regulated and unregulated substances in drinking water related to the use of plastic pipes, characterizes potential health hazards, and describes uncertainties associated with human health and exposure in need of further research. Of particular public health concern is the potential for sensitive populations to be exposed to short-term elevations in leachates during critical periods, and for co-occurring leachates targeting the same organ(s) and/or sharing a common mode of toxic action to have additive or synergistic effects. Contaminants are measured in the distribution system, not at the tap where human exposure actually occurs. For increased health protection, it is important to identify compounds that migrate from plastic pipes into drinking water and to better quantify human exposures and health hazards to these substances and their degradates. - [17] Andrew J. Whelton, Andrea M. Dietrich, Daniel L. Gallagher, "Chapter 6 Impact of Chlorinated Water Exposure on Chemical Diffusivity and Solubility,

Surface and Bulk Properties of HDPE and PEX Potable Water Pipe", in Advancing Potable Water Infrastructure through an Improved Understanding of Polymer

Pipe Oxidation, Polymer–Contaminant Interactions, and Consumer Perception of Taste, Andrew James Whelton

Dissertation submitted to the Faculty of the

Virginia Polytechnic Institute and State University

In partial fulfillment of the requirements for the degree of

DOCTOR OF PHILOSOPHY

In

Civil Engineering

Andrea M. Dietrich, Chair

Daniel L. Gallagher

Marc A. Edwards

Brian J. Love

James M. Tanko, April 2, 2009

Blacksburg, Virginia. Abstract: While more than 100 years of research has focused on removing acute and chronic health

threats from water, substantially less study has focused on potable water infrastructure and water

quality deterioration, monitoring technologies, and relationships between water taste and

consumer health. These knowledge–gaps have left infrastructure users, owners, regulators, and

public health professionals largely unaware of how premise and buried polymer water pipes

deteriorate and sorb/ desorb organic contaminants during normal operations and following water

contamination events. These knowledge–gaps also prevent infrastructure managers from

producing drinking water that optimizes mineral content for both water taste and health benefits,

and employing a monitoring tool capable of immediately detecting water contamination or

equipment failures.

Research was conducted to address these challenges using analytical chemistry,

environmental engineering, food science, polymer chemistry, public health, and material science

principles. This work was enhanced by collaborations with sixteen American water utilities and

the National Institute for Standards and Technology. These efforts were funded by the National

Science Foundation, American Water Works Association, and the Water Research Foundation.

Research results are unique and provide important scientific contributions to the public

health, potable water, and material science industries. Particular achievements include the: (1)

Evaluation of linkages between minerals, water palatability, and health useful for water

production and public health decisions; (2) Creation of a novel infrastructure and water quality

surveillance tool that has begun water utility implementation in the USA; (3) Development of an

accelerated chlorinated water aging method with stable water pH, free chlorine, and alkalinity

concentration that enables interpretation of polymer pipe surface and bulk characteristic changes;

(4) Discovery that polar compounds are 2–193% more soluble in PEX than HDPE water pipes;

(5) Finding that several polymer and contaminant properties can be used to predict contaminant diffusivity and solubility during sorption and desorption in new, lab aged, and water utility PE

pipes; and the (6) Discovery that chlorinated water exposure of HDPE and PEX pipes increases

polar contaminant diffusivity during sorption by 50–162% and decreases diffusivity during

desorption as much as 211%. Outcomes of this work have domestic and global significance, and

if engaged, can greatly improve public health protection, potable water infrastructure operations,

water quality, sustainability, and regulation. - [18] Chemax, "Cross-Linked Polyethylene Tubing and Water Contamination", retrieved 2/17/2013, original source: http://www.chemaxx.com/polytube1.htm [copy on file as [Water Contamination chemical investigation.pdf]

- [19] Ingun Skjevrak, Anne Due, Karl Olav Gjerstad, Hallgeir Herikstad "Volatile organic components migrating from plastic pipes (HDPE, PEX and PVC) into drinking water", Water Research Volume 37, Issue 8, April 2003, Pages 1912–1920

Abstract: High-density polyethylene pipes (HDPE), crossbonded polyethylene pipes (PEX) and polyvinyl chloride (PVC) pipes for drinking water were tested with respect to migration of volatile organic components (VOC) to water. The odour of water in contact with plastic pipes was assessed according to the quantitative threshold odour number (TON) concept. A major migrating component from HDPE pipes was 2,4-di-tert-butyl-phenol (2,4-DTBP) which is a known degradation product from antioxidants such as Irgafos 168®. In addition, a range of esters, aldehydes, ketones, aromatic hydrocarbons and terpenoids were identified as migration products from HDPE pipes. Water in contact with HDPE pipes was assessed with respect to TON, and values ⩾4 were determined for five out of seven brands of HDPE pipes. The total amount of VOC released to water during three successive test periods were fairly constant for the HDPE pipes. Corresponding migration tests carried out for PEX pipes showed that VOC migrated in significant amounts into the test water, and TON ⩾5 of the test water were observed in all tests. Several of the migrated VOC were not identified. Oxygenates predominated the identified VOC in the test water from PEX pipes. Migration tests of PVC pipes revealed few volatile migrants in the test samples and no significant odour of the test water. - [20] Andrew J. Whelton, Ph.D., M.ASCE; Andrea M. Dietrich, Ph.D., Aff.ASCE; and Daniel L. Gallagher, Ph.D., P.E., M.ASCE, ”Contaminant Diffusion, Solubility, and Material Property Differences between HDPE and PEX Potable Water Pipes.” J. Environ. Eng., 136(2), 227–237.

doi: 10.1061/(ASCE)EE.1943-7870.0000147

Abstract: the objectives of this work were to identify differences between the composition, bulk properties, contaminant diffusivity and solubility for new high-density polyethylene (HDPE) pipe and crosslinked polyethylene (PEX) pipe, as well as determine which contaminant and polymer properties are useful for predicting contaminant fate in water pipe. Variations in PE pipe density (0.9371–0.9547 g/cm3) , crystallinity (69–72%), crosslinking (60 and 76%), and oxidative induction time (33 to >295 min .) were detected. While numerically these differences seem minor, results show that slight material differences have a notable effect on contaminant diffusivity and solubility. Nonpolar contaminant diffusivity and solubility were best predicted by bulk density. Polar contaminants were more soluble and diffused faster through PEX than HDPE pipes because PEX pipes contained a greater amount of oxygen. For all materials, dipole moment and Log Kow were good predictors of contaminant fate and molecular volume was only useful for predicting diffusivity and solubility values for haloalkane and nonpolar aromatic contaminants. - [21] Jia Tang, Daniel L. Gallagher, and Andrea M. Dietrich. (2013) Predicting Permeation of Organic Contaminants into Polyethylenes. Journal of Environmental Engineering 139:2, 205-212

Online publication date: 1-Feb-2013.

Abstract:

A model was developed and validated for predicting solubility and diffusion coefficients for contaminants permeating polyethylene (PE) materials used for water pipes and geomembranes. Model development was based on diffusivity and solubility of 13 contaminants and six PE materials that were new and/or aged in chlorinated water. Physical and chemical properties of the contaminants and PEs were included as variables in the model. Tree regression was used to select variables, and multiple linear regression was used to develop predictive equations for contaminant diffusivity and solubility in PE. Organic contaminant properties, especially dipole moment and octanol-water partition coefficient, had greater predictive capability than PE properties. Coefficients of determination (R2)>0.8 were obtained for the multiple linear regressions. Model coefficients changed slightly between new PE materials and chlorine-aged PE, but these changes were not statistically significant. Good agreement was demonstrated between model predictions and measured data from an independent data set. These results provide guidance for material selection for both water pipes and geomembranes and assessing contamination potential. - [22] Andrew J. Whelton, Andrea M. Dietrich, and Daniel L. Gallagher. (2011) Impact of Chlorinated Water Exposure on Contaminant Transport and Surface and Bulk Properties of High-Density Polyethylene and Cross-Linked Polyethylene Potable Water Pipes. Journal of Environmental Engineering 137:7, 559-568

Online publication date: 1-Jul-2011. Abstract:

The aim of this work was to determine if the aging of polyethylene (HDPE, PEX-A and PEX-B) water pipes by exposure to chlorinated water altered polar and nonpolar contaminant diffusivity and solubility by analyzing new, laboratory-aged, and exhumed water-distribution system polyethylene (PE) pipes. After 141 days of aging in pH 6.5 water with 45 mg/L free chlorine, the surface chemistry and bulk properties of PEX-A pipe were unaffected. Carbonyl bonds (σ=1,713 cm−1) were detected on the surfaces of HDPE and PEX-B pipe, and these oxygenated surfaces became more hydrophilic, resulting in statistically significant increases in diffusion rates. All 10 contaminant and four pipe material combinations had diffusivity increases on average of 50% for polar contaminants and 5% for nonpolar contaminants. Contaminant solubility was slightly increased for aged PEX-A and slightly decreased for PEX-B pipes. Toluene and trichloromethane diffusivity and solubility values for 7- to 25-year-old buried water utility pipes were similar to values for new and laboratory-aged HDPE-based materials. Because chlorinated water exposure alters how polar contaminants interact with aged PE pipes, results of this work should be considered in future health risk assessments, water quality modeling, pipe performance, and service-life considerations. - [23] ANDREW J. WHELTON & TINH NGUYEN, "Contaminant Migration from Polymeric Pipes used in Buried Potable Water Distribution Systems: A Review", Critical Reviews in Environmental Science and Technology, February 2012 posted online,

Abstract: Polymeric pipes are increasingly being installed in water distribution systems because of their many advantages. Contaminant migration from polymer pipes into drinking water is a growing concern in the United States and environmental engineers are evaluating the role of these materials on water quality, system operation, and regulatory compliance. To aid these efforts and serve as a source of background information, this paper critically reviews available literature on polymeric potable water pipes in use, known contaminants released from in–service and new piping, their perceived sources, and outlines future challenges in the U.S. and abroad. - [24] Andrew James Whelton, "Advancing Potable Water Infrastructure through an Improved Understanding of Polymer Pipe Oxidation, Polymer–Contaminant Interactions, and Consumer Perception of Taste", Dissertation submitted to the Faculty of the Virginia Polytechnic Institute and State University In partial fulfillment of the requirements for the degree of DOCTOR OF PHILOSOPHY In Civil Engineering, April 2, 2009 Blacksburg, Virginia, retrieved 2/17/2013, original source http://scholar.lib.vt.edu/theses/ available/etd-04162009-113815/unrestricted/ FINALWheltonDissertationMay09.pdf#page=158

- [25] Website: GreenBuildingAdvisor.com, "PEX vs Copper", retrieved 2/18/2013, original source: http://www.greenbuildingadvisor.com/ community/forum/green-products-and-materials/ 16256/pex-vs-copper [copy on file as PEX vs Copper _ GreenBuildingAdvisor.pdf]

- [26] Website: GreenBuildingAdvisor.com," How Safe is PEX tubing?", retrieved 2/18/2013, original source: http://www.greenbuildingadvisor.com/ blogs/dept/qa-spotlight /how-safe-pex-tubing [copy on file as How Safe is PEX tubing_GreenBuildingAdvisor.pdf]

- [27] Lauren Hunter, "California’s PEX Battle Continues", Remodeling Magazine, June 2010, Website: Builderonline.com, "x", retrieved 2/18/2013, original souirce: http://www.builderonline.com/legislation/californias-pex-battle-continues.aspx [copy on file as California’s PEX Battle Continues - Plumbing, Legal Issues, Legislation - Builder Magazine.pd]

- [28] Contractor Magazine, "California approves PEX for plumbing — again- Contractor Magazine.pdf", retrieved 2/18/2013, original source: http://contractormag.com/news/ california-pex-plumbing-1234 [copy on file as California approves PEX for plumbing — again- Contractor Magazine.pdf]

- Cheating on water tests: Testing Water for Real Estate Transactions - make sure your water test is valid

- Drinking Water Testing Advice for home buyers home owners home inspectors

- Drinking Water Contaminant Levels - Maximum Allowed

- Lead Contamination in Drinking Water: Testing & Correction - Advice (This Article)

- Lead Testing & Correcting Contamination from Lead Water Supply Lines/Entry Mains - Lead Pipe Problems/Advice

- Water testing for Pesticides: comprehensive and pesticides-example parameters

- CONTAMINANT CLASSES, in WATER & links to home buyer advice about water testing, drinking water, water supply

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.