Septic System D-Box Splitters for Drainfield Rest & Recovery

Septic System D-Box Splitters for Drainfield Rest & Recovery

Use Splitters / Diverter Valves at the Septic System Distribution Box

- POST a QUESTION or COMMENT about septic system D-box installation, inspection, troubleshooting, and repair or replacement

Septic drop box splitters:

Use of special control valves in the septic system D-box or distribution box can give sections of the septic soak bed or leachfield or drainfield a rest, allowing for drainfield recovery.

This article describes septic d-box splitters or flow diverters or flow control valves & their use and gives product sources - where to buy a D-box splitter for drainfield R&R.

Septic system D box installation, specifications, inspection, diagnosis, and repair: in this article series about septic system drop boxes we describe the best procedures for locating and inspecting, repairing or replacing the septic drainfield distribution box, or the "D-box" or "Splitter box".

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Septic System D-Box Splitters - Drainfield Resting

Reader Question: What's the difference between a septic system D-box and a Splitter?

What is the difference in splitter box and a D box? - T.C.

Reply: why we might need a Zoeller Tru-Flow Splitter in place of a conventional Septic D-box - alternating drainfields & effluent flow balancing

Basically there is no difference in function between a D-box and a Splitter box. All D-boxes have some capability of adjusting the flow of effluent among different D-box outlets - a technique that can extend drainfield life by giving some drainfield sections a rest for two years or so between services.

In some literature the control that permits diverting effluent among drainfield segments, or shutting it off entirely, is called a splitter valve.[4] In other installations, a simple manual plug or cap is inserted or adjusted at each outlet opening inside the distribution box.

Some "splitter" boxes such as Zoeller's are more sophisticated than the simple concrete or plastic Distribution Boxes illustrated in the article above.[3]

Zoeller Pump Co who make septic system grinder pumps and other onsite wastewater piping and pump components, also produce and sell component that most of us call a "distribution box" and that accomplishes that function - routing effluent among drainfield lines: the Zoeller Splitter System. What's the difference?

In a conventional concrete D-box, it's just that: a plastic or concrete or fiberglass "box" into which one pipe delivers septic effluent from the septic tank, and from which two or more pipes carry effluent to drainfield trenches, galleys, or other disposal systems.

The distribution box routes effluent among the various lines and if properly installed we hope effluent is distributed evenly

. Some D-boxes include a round cover with an eccentric hole that can be rotated up or down to balance the effluent load among different drainfield sections.

Higher velocity pumped septic effluent may require careful effluent distribution control in the D-box - the Splitter

Zoeller's Splitter uses a series of internal baffles to control the routing of effluent among drainfield lines.

One reason we might need the baffles and more precise control of effluent distribution through the D-box (or Splitter) is that Zoeller, who manufacture sewage grinder pumps and septic effluent pumps, (we pose) may have found that pumped septic effluent arrives in the Splitter (or D-box) at a higher velocity than effluent that drains into the box from a septic tank by gravity.

At high velocity, effluent entering a conventional D-box may not flow uniformly among the multiple box outlets - instead it would charge across the box and flow mostly into the effluent line directly across from the inlet pipe.

Zoeller's baffles appear intended to prevent that problem by diverting flow uniformly among the various Splitter box outlets.

Zoeller's Tru-Flow [D-box] Splitter system includes diverter adjustments that help you fine tune and balance the effluent flow among various drainfield sections. The system can handle varying septic flow rates depending on the number of openings in use in the "box" - that is, depending on the number of outlets and drainfield sections that are in use.

Septic Effluent Flow Rate Capacity - Zoeller's Tru-Flo Splitter [D-box] |

|

| Number of outlet openings (drainfield segments fed) | Maximum effluent inflow rate handled by the Splitter |

| 5 openings | 30 gpm |

| 4 openings | 21 gpm |

| 3 openings | 17 gpm |

| 2 openings | 13 gpm |

Notice: other septic diverters or flow control valves from other manufacturers will have different operating flow rates and properties.

See our contact information for Zoeller just below and also at at the reviewers section at the end of this article for a link to the Zoeller D-Box-Splitter for septic effluent distribution system information.

Watch out: Zoeller warns that if you use this device, which does a more careful job of routing effluent among the different drainfield branches, it is clog-prone if you don't include a septic filter in the system at the effluent outlet end. Indeed, an effluent filter will protect and extend the life of any drainfield and its components.

- American Manufacturing Co., Inc., THE BULL RUN VALVE INSTRUCTIONS [PDF] (2016) & Product Data, American Manufacturing C. Inc., 22011 Greenhouse Rd. Elkwood, VA 22718 USA Tel: 800-345-3132 Email: info@americanonsite.com Website: americanonsite.com retrieved 2015/04/15 original source: https://www.americanonsite.com/american/catalog/brv.html

- Zoeller Pump Co.,3649 Cane Run Rd.

Louisville, KY USA 40211, USA, Tel: 001-502-778-2731, Website: www.zoeller.com, Email for Technical Support: zcotechnical@zoeller.com, International Accounts

Phone: +1-502-778-2731 ext. 8208

Fax: +1-502-774-3624

Email: billyw@zoeller.com Zoeller also has offices also in Taiwan, Canada, and Mexico.

Zoeller On-Site Wastewater Products Tru-Flow Splitter System Installation Instructions and Preinstallation Checklist [PDF] retrieved 7/12/2014, original source: http://literature.puertoricosupplier.com/002/HJ1253.pdf

Reader Question: one side of my fields never dries out, we installed speed levelers and a new D-box. Should we cap off the wet area lines?

I have 8 lines coming off my d box. my yard is slightly pitch to one side. that side also sees most of the rain water. The surface never seems to fully dry like my other lines. speed levelers were installed when the dbox was replaced. should those 2 lines be capped and shut off for a while to regain a better saturation point? i you, JB 5/10/12

Reply:

JB:

I agree with your idea to cap off saturated drainfield lines. Drainfield trenches tend to wear out (clog the soil) beginning at the trench end most distant from the D-box, slowly working the clogging back towards the D-box. Giving the drainfield a rest for 5 years or more might help those sections recover provided that they are not being soaked from some other water source.

Keep in mind that effluent breakout at ground surface is not only a failure indicator, it is unsanitary. In sum, if the area is wet, the effluent distribution lines in that area are not treating effluent anyway, just contaminating the environment.

Finally, if the wet area were in say the last 5 feet of a 60-foot line, you might try excavating and capping off the wet ends to see if that gives you longer use of the rest of the leach line.

Question: my septic D-box is flooded - is there a Diverter Valve for a second Seepage Pit?

2019/04/15 JP said

How can I diagnose if my issue is the D-box or seepage pits? Also can you tell if there is a diverter valve from these picture? I recall that my septic inspector (15 years ago) said something about selecting and alternating pits. I am not sure how to do this. Any recommendations?

This Q&A were posted originally at SEPTIC D-BOX INSTALL, LOCATE, REPAIR

[Click to enlarge any image]

Reply: (mod) - Cescription of Septic Flow Diverter Valves & Alternating Bed Septic Switch Frequency

JP

JP

If that flooded box in the left of the photo is your D-box and if it's top is off then it's flooded.

That tells us that the drainfield or seepage pit to which the D-box is sending effluent is either blocked or in total failure.

Illustration: this is a 3-way Bull Run diverter valve from American Manufacturing Co., cited below.

A diverter valve, also sometimes called a flow control valve, for septic systems is in essence a switch that will either

1. choose which of two (or more) destination drains, pipes, drainfields, or seepage pits to which to send wastewater

or in some designs

2. can adjust the balance to split the routing wastewater between two destinations simultaneously - i.e. niether of them is shut off.

If you have a septic design with alternating seepage pits then yeah you might have a diverter valve that swaps between them.

Often the diverter valve has a standpipe and a cap that's pulled off to permit using of a simple T-handled tool to turn the valve - that avoids having to dig it up.

You could look under the white cap on the standpipe in the upper right of your photo to see what's there - it could be

- an inspection port

- a vent

- access to a diverter valve

Let me know what you find.

The bad news is that once a seepage pit is flooded or stops accepting effluent it's basically shot. There are fellows who, for a fee, will jet the bottom (if it's open to soil) or try other magic bullets to "restore" a failed seepage pit (or drywell).

In my experience these rarely work or rarely give relief for more than a short time.

Watch out: jetting a home made or site built seepage pit or drywell can cause it to collapse - if someone falls in it's a quick and ugly death. We've reported on such fatalities here.

Read more at

SEEPAGE PITS

and at

The following excerpt is from "Operation and Maintenance of Your Sewage Treatment System" published by the Ohio health department.

Diverter Valve/Distribution Box

If you have a diverter valve, the valve separates the leach field into two fields. The valve should be turned every three months to alternate the field and allow one field to rest while the other is absorbing the wastewater. If you have a distribution box, the wastewater is distributed to each leach line equally.

If you have a diverter valve, the valve separates the leach field into two fields. The valve should be turned every three months to alternate the field and allow one field to rest while the other is absorbing the wastewater. If you have a distribution box, the wastewater is distributed to each leach line equally.

Each pipe in the box has a turn dial cap with a hole in the cap to allow water to flow into the leach line. Half of the caps should be turned with the holes up stop water flow and half should be turned with the holes down to allow for flow.

Every three months every cap should be turned 180 degrees to either allow flow or stop the flow. This will allow each line to rest while the others are absorbing wastewater. - Athens OH DOH retrieved 2019/04/15 original souirce: http://www.health.athens.oh.us/environmental/om_sewage.html 2019/04/15

Really? In our OPINION "every three months" is questionable advice for most septic fields in most soils, designs, and uses.

Why? Because once a biomat has begun to clog the soil around a drainfield trench or septic seepage pit wall it can take a year or even several years of total rest for the soil bacteria to break down the biomat layer enough to restore the field and soil percolation rate.

Frequent diverter valve switching might allow wet soils to "dry out" but that's not getting rid of the biomat. And if your septic fields or seepage pit are failing because they're flooded, just drying out is not likely to give more than temporary relief.

The underlying problem - flooding from groundwater - needs to be fixed OR if the flooding is because of soil clogging, the field or pit needs replacement - or a mutli-year rest.

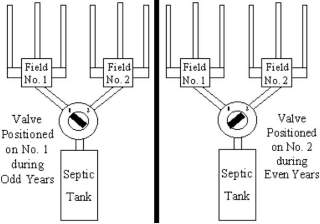

The sketch below illustrating how a diverter valve might be used to manage two alternating drainfields is excerpted from instructions from American Manufacturing Co. who produce the Bull Run valve I illustrated earlier.

- American Manufacturing Co., Inc., THE BULL RUN VALVE INSTRUCTIONS [PDF] (2016) & Product Data, American Manufacturing C. Inc., 22011 Greenhouse Rd.

Elkwood, VA 22718 USA Tel: 800-345-3132 Email: info@americanonsite.com Website: americanonsite.com retrieved 2015/04/15 original source: https://www.americanonsite.com/american/catalog/brv.html

The company's septic system products include drip systems, micromound systems, vaulted media filters, recirculting media filters, valves, disinfection systems including a tablet chlorinator, a timer-pump, and design management & monitoring drawings for alternating bed septic systems.

Reader Comments, Questions & Answers About The Article Above

Below you will find questions and answers previously posted on this page at its page bottom reader comment box.

Reader Q&A - also see RECOMMENDED ARTICLES & FAQs

On 2021-04-23 by (mod) - cost of septic effluent splitters at the D-Box

@Anonymous,

@Anonymous,

A typical septic D-box lid costs under $20. U.S.

to which

you would add the cost of labor to excavate, inspect, clean the surfaces, install, re-bury.

About your septic effluent splitter valve, if you are talking about a true valve, the cost can be $50 to $100 depending on model and features.

Here is an example

American Mfg Bull Run™ Septic Valve, 4 Inch For PVC SCH 40 Pipe selling for about $85. U.S.

On 2021-04-23 by Anonymous

how much does it cost to replace the distribution box lid?

On 2021-04-23 by Anonymous

how much does it cost to adjust a splitter valve

On 2020-02-23 - by (mod) -

Victoria:

Indeed we do NOT want surface runoff or ground water leaking into a septic tank nor piping nor D-box.

On 2020-02-23 by Victoria

Thank you so much for your help! After reading everything, that is what I am afraid of!! I will jot be able to get the lid opened for a few days, as it's suppose to be raining here, so I will be back within the next week, hopefully, with what's going on inside of the D Box.

Is there suppose to be a seal, or tight fit where the pipe goes into the D box from the septic tank? I believe I read somewhere that, on the cement boxes, like ours, they have a seal or asphalt around the piping? Just want to be totally sure what it's suppose to be like in there when I get it open.

Thanks again so much! I'll be back soon! :-)

On 2020-02-23 - by (mod) -

Victoria

Sorry to bring bad news, but if there were solids all the way to the septic tank lid underside then the tank was flooded and its outlet probably blocked by sewage; worse, having pushed solid sewage into the drainfield means a shortened or ended drainfield life.

Finding water in the yard, if it's coming from your house waste piping, tells us that the system is in failure.

It sounds as if you uncovered the D-box (which means you landed on the right page here at InspectApedia.com).

Certainly it'd be reasonable to have a plumber clear the line between septic tank and D-box but consider that if there are solids in that line then they've also been pushed to the drainfield itself.

Good going.

Now, opening the D-box will give us more diagnostic information.

If you lift the lid of the D-box and effluent is standing in the box and in its outlet pipes then the drainfield itself is either blocked or flooded (and in failure).

Bottom line:

No, effluent should not be backing up and leaking out of the D-box. That observation suggests that septic tank effluent is reaching the D-box but not being accepted into the drainfield.

On 2020-02-23 by Victoria

My husband and I just purchased a home about 7 months ago. Around Thanksgiving we noticed some water in a hole our dog dug. We ended up getting the septic tank pumped, which REALLY needed it. The person that pumped it said it looks as if it had never been pumped and had solids all the way to the lid.

Now, a month or so after, there's water again, we dug down and its coming from around a pipe thats going into a concrete box further down from the septic tank.

I've read most of the information on this site and believe that that is the outlet pipe going into the distribution box,

but my question is, should water be able to come out of the box from around the pipe from septic tank?

After all of the reading, it doesn't seem like it should, but nothing says so specifically. Also, if it isn't suppose to, what could the problem be? Or, shall I say, the cause?

On 2020-02-07 - by (mod) -

Oren

In the ARTICLE INDEX see SEPTIC DOSING SYSTEMS.

It ought to be pretty easy to install a pumping chamber and grinder pump combined with a dosing system control that simply alternates between two outlets to two separate tanks. You want to compare the cost of installing all of that with simply installing a larger septic tank or piping your two existing septic tanks in series.

On 2020-02-07 by Oren Reedy

Does anyone have a solution to split flow from an establishment (solids) into 2 septic tanks?

...

Continue reading at SEPTIC DRAINFIELD INSPECTION & TEST or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see these

Recommended Articles

- ALTERNATING BED SEPTIC SYSTEMS

- SEPTIC D-BOX INSTALL, LOCATE, REPAIR - home for septic distribution box, drop box, D-box

- SEPTIC D-BOX COVERS - cover leaks, cover sealing, cover safety at the septic system distribution box

- SEPTIC D-BOX FLOODING - causes & cures for flooding & leaks at the septic system distribution box or Drop Box

- SEPTIC D-BOX INSPECTION - How to inspect the septic system distribution box for clues of septic drainfield condition

- SEPTIC D-BOX LOCATION - how to find the D-box

- SEPTIC D-BOX PIPING - solid vs. perforated piping

- SEPTIC D-BOX SPECIFICATIONS - sanitary code examples of D-box requirements

- SEPTIC D-BOX SPLITTERS - Using a D-box control or a Splitter Valve for drainfield resting & restoration

- SEPTIC D-BOX TEMPORARY REPAIR - temporary repair bypassing the Drop Box may work in a few cases

- SEPTIC D-BOX TROUBLESHOOTING - simple repairs at the D-Box can improve septic drainfield performance and may eliminate a Tipped D-box, Distribution -Box Leaks, Drop Box Odor

Suggested citation for this web page

SEPTIC D-BOX SPLITTERS at InspectApedia.com - online encyclopedia of building & environmental inspection, testing, diagnosis, repair, & problem prevention advice.

Or see this

INDEX to RELATED ARTICLES: ARTICLE INDEX to SEPTIC DRAINFIELDS & D-BOXES

Or use the SEARCH BOX found below to Ask a Question or Search InspectApedia

...

Ask a Question or Search InspectApedia

Try the search box just below, or if you prefer, post a question or comment in the Comments box below and we will respond promptly.

Search the InspectApedia website

Note: appearance of your Comment below may be delayed: if your comment contains an image, photograph, web link, or text that looks to the software as if it might be a web link, your posting will appear after it has been approved by a moderator. Apologies for the delay.

Only one image can be added per comment but you can post as many comments, and therefore images, as you like.

You will not receive a notification when a response to your question has been posted.

Please bookmark this page to make it easy for you to check back for our response.

Our Comment Box is provided by Countable Web Productions countable.ca

Citations & References

In addition to any citations in the article above, a full list is available on request.

- New York State Department of Health, APPENDIX 75-A WASTEWATER TREATMENT STANDARDS - INDIVIDUAL HOUSEHOLD SYSTEMS , [PDF] New York State Department of Health, 3 February 2010, retrieved 3/1/2010, original source: https://www.health.ny.gov/regulations/nycrr/title_10/part_75/appendix_75-a.htm

- [1] Readers of this page should also see System Design Regulations 75-A.7 Distribution lines, distribution boxes, gravity flow, pressure distribution, dosing, siphons design specifications for septic systems.

- [2] Thanks to reader Nicholas Day for discussing D-box troubles and repairs, September 2010

- [3] Zoeller Pump Company, 3649 Cane Run Rd., Louisville, KY 40211, Phone: 1-800-928-7867, 502-778-2731

Fax: 502-774-3624. Technical support and/or quote related emails: zcotechnical@zoeller.com. Zoeller produces just about every kind of septic, sewage, effluent, grinder, and sump pump. Homeowners who need a sewage pump are asked to contact their local representative or retail sales outlet. Zoeller classes their pumps into these categories:

- Grinder pumps, such as Zoeller's 810/815 Turnkey Grinder Systems, 800-series Grinder Pumps, Cold-Climate grinder pumps, Simplex prepackaged grinder pump systems, and Simplex and Duplex (two pumps) grinder systems including four outdoor use.

- Utility, pedestal, & gas engine pumps. These are portable gas-engine powered pumps used typically in construction, service, or emergencies

- Sewage & Dewatering pumps, such as certain Aqua-Mate Models and Waste-Mate models, and Sewage-Waste 600-series pumps

- Splitter for septic effluent distribution. Web search 5/1/12, original source

https://app.qleapahead.com/rtp/LibraryGet.aspx?asset=85356,63 [copy on file as septic/D-boxes/Zoeller_D-BOx_Splittert.pdf ] Website: www.zoeller.com - Sump, Effluent, Dewatering pumps, such as Water Ridd'r , Mighty-Mate, Aqua-Mate, Flow-Mate, and High Head Flow-Mate pumps - of certain models - be sure to read the manufacturer's intended use for a pump model before purchasing it

- [4] "Drainfield Rehabilitation", Pipeline, Winter 2005, Vol. 16, No. 1, NESC, National Environmental Services Center, 800-624-8301 [copy on file as [/septic/D-boxes/NESC_2005-16_1.pdf

- [5] Advanced Onsite Wastewater Systems Technologies, Anish R. Jantrania, Mark A. Gross. Anish Jantrania, Ph.D., P.E., M.B.A., is a Consulting Engineer, in Mechanicsville VA, 804-550-0389 (2006). Outstanding technical reference especially on alternative septic system design alternatives. Written for designers and engineers, this book is not at all easy going for homeowners but is a text I recommend for professionals--DF.

- [6] Builder's Guide to Wells and Septic Systems, Woodson, R. Dodge: $ 24.95; MCGRAW HILL B; TP; Quoting from Amazon's description: For the homebuilder, one mistake in estimating or installing wells and septic systems can cost thousands of dollars. This comprehensive guide filled with case studies can prevent that. Master plumber R. Dodge Woodson packs this reader-friendly guide with guidance and information, including details on new techniques and materials that can economize and expedite jobs and advice on how to avoid mistakes in both estimating and construction. Chapters cover virtually every aspect of wells and septic systems, including on-site evaluations; site limitations; bidding; soil studies, septic designs, and code-related issues; drilled and dug wells, gravel and pipe, chamber-type, and gravity septic systems; pump stations; common problems with well installation; and remedies for poor septic situations. Woodson also discusses ways to increase profits by avoiding cost overruns.

- [7] Country Plumbing: Living with a Septic System, Hartigan, Gerry: $ 9.95; ALAN C HOOD & TP; Quoting an Amazon reviewer's comment, with which we agree--DF:This book is informative as far as it goes and might be most useful for someone with an older system. But it was written in the early 1980s. A lot has changed since then. In particular, the book doesn't cover any of the newer systems that are used more and more nowadays in some parts of the country -- sand mounds, aeration systems, lagoons, etc.

- [8] Onsite Wastewater Disposal, R. J. Perkins; Quoting from Amazon: This practical book, co-published with the National Environmental Health Association, describes the step-by-step procedures needed to avoid common pitfalls in septic system technology. Valuable in matching the septic system to the site-specific conditions, this useful book will help you install a reliable system in both suitable and difficult environments. Septic tank installers, planners, state and local regulators, civil and sanitary engineers, consulting engineers, architects, homeowners, academics, and land developers will find this publication valuable.

- [9] Onsite Wastewater Treatment Systems, Bennette D. Burks, Mary Margaret Minnis, Hogarth House 1994 - one of the best septic system books around, suffering a bit from small fonts and a weak index. (DF volunteers to serve as indexer if Burks/Minnis re-publish this very useful volume.)While it contains some material more technical than needed by homeowners, Burks/Minnis book on onsite wastewater treatment systems a very useful reference for both property owners and septic system designers. We refer to it often.

- [10] Septic Tank/Soil-Absorption Systems: How to Operate & Maintain [ copy on file as /septic/Septic_Operation_USDA.pdf ] - , Equipment Tips, U.S. Department of Agriculture, 8271 1302, 7100 Engineering, 2300 Recreation, September 1982, web search 08/28/2010, original source: http://www.fs.fed.us/t-d/pubs/pdfimage/82711302.pdf

- [11] Percolation Testing Manual, CNMI Division of Environmental Quality, PO Box 501304, Saipan, MP 96950

- [12] Septic System Owner's Manual, Lloyd Kahn, Blair Allen, Julie Jones, Shelter Publications, 2000 $14.95 U.S. - easy to understand, well illustrated, one of the best practical references around on septic design basics including some advanced systems; a little short on safety and maintenance. Both new and used (low priced copies are available, and we think the authors are working on an updated edition--DF. Quoting from one of several Amazon reviews: The basics of septic systems, from underground systems and failures to what the owner can do to promote and maintain a healthy system, is revealed in an excellent guide essential for any who reside on a septic system. Rural residents receive a primer on not only the basics; but how to conduct period inspections and what to do when things go wrong. History also figures into the fine coverage.

- [13] Test Pit Preparation for Onsite Sewage Evaluations, State of Oregon Department of Environmental Quality, Portland OR, 800 452-4011. PDF document. We recommend this excellent document that offers detail about soil perc tests, deep hole tests, safety, and septic design. Readers should also see SEPTIC SOIL & PERC TESTS and for testing an existing septic system, also see Dye Tests

- [14] Grass is Always Greener Over the Septic Tank, Bombeck, Erma: $ 5.99; FAWCETT; MM; This septic system classic whose title helps avoid intimidating readers new to septic systems, is available new or used at very low prices. It's more entertainment than a serious "how to" book on septic systems design, maintenance, or repair. Not recommended -- DF.

- [15] US EPA ONSITE WASTEWATER TREATMENT SYSTEMS MANUAL Top Reference: US EPA's Design Manual for Onsite Wastewater Treatment and Disposal, 1980, available from the US EPA, the US GPO Superintendent of Documents (Pueblo CO), and from the National Small Flows Clearinghouse. Original source http://www.epa.gov/ORD/NRMRL/Pubs/625R00008/625R00008.htm

- [16] Water Wells and Septic Systems Handbook, R. Dodge Woodson. This book is in the upper price range, but is worth the cost for serious septic installers and designers.

Quoting Amazon: Each year, thousands upon thousands of Americans install water wells and septic systems on their properties. But with a maze of codes governing their use along with a host of design requirements that ensure their functionality where can someone turn for comprehensive, one-stop guidance? Enter the Water Wells and Septic Systems Handbook from McGraw-Hill.

Written in language any property owner can understand yet detailed enough for professionals and technical students this easy-to-use volume delivers the latest techniques and code requirements for designing, building, rehabilitating, and maintaining private water wells and septic systems. Bolstered by a wealth of informative charts, tables, and illustrations, this book delivers:

* Current construction, maintenance, and repair methods

* New International Private Sewage Disposal Code

* Up-to-date standards from the American Water Works Association

- [17] Wells and Septic System, Alth, Max and Charlet, Rev. by S. Blackwell Duncan, $ 18.95; Tab Books 1992. We have found this text very useful for conventional well and septic systems design and maintenance --DF. Quoting an Amazon description:Here's all the information you need to build a well or septic system yourself - and save a lot of time, money, and frustration. S. Blackwell Duncan has thoroughly revised and updated this second edition of Wells and Septic Systems to conform to current codes and requirements. He also has expanded this national bestseller to include new material on well and septic installation, water storage and distribution, water treatment, ecological considerations, and septic systems for problem building sites.

- [18] The NSFC Products List has an excellent list of design manuals/modules National Small Flows Clearinghouse (NSFC) now (2019/12/13) hosted at http://www.nesc.wvu.edu/ Tel: 304-293-4191 e-mail info@mail.nesc.wvu.edu.

The National Small Flows Clearinghouse (NSFC) was funded by the U.S. Environmental Protection Agency (EPA) to help America's small communities and individuals solve their wastewater problems through objective information about onsite wastewater collection and treatment systems. NSFC products and information are the only national resource of its type, dealing with small community wastewater infrastructure. or by telephone 800-624-8301 - Our recommended books about building & mechanical systems design, inspection, problem diagnosis, and repair, and about indoor environment and IAQ testing, diagnosis, and cleanup are at the InspectAPedia Bookstore. Also see our Book Reviews - InspectAPedia.

- In addition to citations & references found in this article, see the research citations given at the end of the related articles found at our suggested

CONTINUE READING or RECOMMENDED ARTICLES.

- Carson, Dunlop & Associates Ltd., 120 Carlton Street Suite 407, Toronto ON M5A 4K2. Tel: (416) 964-9415 1-800-268-7070 Email: info@carsondunlop.com. Alan Carson is a past president of ASHI, the American Society of Home Inspectors.

Thanks to Alan Carson and Bob Dunlop, for permission for InspectAPedia to use text excerpts from The HOME REFERENCE BOOK - the Encyclopedia of Homes and to use illustrations from The ILLUSTRATED HOME .

Carson Dunlop Associates provides extensive home inspection education and report writing material. In gratitude we provide links to tsome Carson Dunlop Associates products and services.