Air Conditioner / Heat Pump FAQs

Air Conditioner / Heat Pump FAQs

Q&A on air conditioner & heat pump inspection, installation, troubleshooting & repair procedures, parts, manuals & codes

- POST a QUESTION or COMMENT about how to diagnose and repair air conditioning and heat pump systems.

Questions & answers on how to buy, diagnose, repair air conditioners & heat pumps:

This air conditioner & heat pump inspection, installation, diagnosis & repair FAQ series lists questions & answers sorted by major air conditioning or heat pump topic.

This article series describes how to inspect and repair all types of residential air conditioning systems (A/C systems). Information for home buyers, owners, and home inspectors about A/C or heat pump system problems. Page top heat pump operating schematic provided courtesy of Carson Dunlop Associates, a Toronto home inspection, education & report writing tool company [ carsondunlop.com ].

InspectAPedia tolerates no conflicts of interest. We have no relationship with advertisers, products, or services discussed at this website.

Air Conditioning or Heat Pump System FAQs Master List

The questions and answers immediately below were posted originally at AIR CONDITIONING & HEAT PUMP SYSTEMS - home. Be sure to see the recommended topics and articles given on that page.

The questions and answers immediately below were posted originally at AIR CONDITIONING & HEAT PUMP SYSTEMS - home. Be sure to see the recommended topics and articles given on that page.

[Click to enlarge any image]

On 2022-07-07 by (mod) - sleeve the suction line passing through a block wall?

@RS1227,

Yes.

See details at REFRIGERANT PIPING INSULATION where you will find the following

Suction lines are cold – 40°F (4.4°C) SST – and cause condensation, even in conditioned spaces. In addition, any heat that enters the refrigerant adds to the superheat and reduces system efficiency.

For these reasons, suction lines should be insulated with a vapor proof insulation. This is a requirement of many building codes. Rubatex is the most common form of refrigerant line insulation.

Keep in mind that the local building code official is the final legal authority on code questions.

However that does not change what is good practice or best practice. That is, even if the local inspector doesn't require insulating of the suction line, it should still be done.

On 2022-07-07 by RS1227

On residential construction, is the line-set/copper tubing/vapor and suction line, required to be sleeved when installed through a cinder block wall?

Mechanical code references pipe duct for installation in concrete floors, but does not specifically state when installed through walls and/or more specifically through block walls.

Allied guidelines for long line installation suggest a PVC sleeve but I cannot find specific reference or requirement for any.

On 2022-04-23 by Inspectapedia Com Moderator

@ Cornelia, Perhaps A/C condensate is being sent into that drain line

On 2022-04-23 by Cornelia

Why do I hear loud dripping noise in the drain pipe in laundry room when AC is on?On 2022-04-22 by Inspectapedia Com Moderator

@ Karen DurmIf your ductwork is lined with a fragile material such as fiberglass, its interior can not be cleaned mechanically such as by sending brushes or devices through the ductwork. Doing so often damages the otherwise stable, coated surface of the insulation such that it sheds fiberglass into building air.

On 2022-04-22 by Karen Durm

I requested rigid ductwork in my house so that it could be cleaned. They are installing now and it appears that the ductwork is lined with some type of product? How will I be able to clean?On 2022-02-12 by Inspectapedia Com Moderator (edited)

@ Trevor Williams

Latent cooling is in essence the energy required to remove moisture from indoor air - dehumidification. Asking if all 5-ton AC units will have the same latent cooling capacity is perhaps a little tricky. On the face of it, 5 tons of cooling capacity, if we keep all building conditions the same (occupants, indoor humidity level, other sources of indoor moisture, air leakage etc.), ought to have the same latent cooling capacity.

OPINION: But I'm not so sure. A simple change such as blower fan speed or even cooling coil design or how moisture is collected and removed in the air handler may cause variations in just how efficiently a given 5-ton cooling system dehumidifies indoor air.And if the cooling capacity is over-sized for the building, the indoor air will be cooled, but it will not be successfully dehumidified.

For other readers

at DEFINITION of HEATING, COOLING & INSULATION TERMS

we provide definitions of sensible and latent heat and cooling, including

There we provide a more scholarly exposition and expert references you might want to review. For example, we cite Shirey (2006) who points out that just how moisture is collected and removed from a cooling coil may affect re-entrainment of moisture back into indoor air between operating cycles of the equipment.

And I don't assume that all air handlers, cooling coils, and condensate collection and removal designs are identical across various 5-ton cooling system air handlers. We certainly see differences that result, in some cases, in moisture blowing off of the coil and into the ductwork (a candidate for re-humidification). Thank you for a helpful question.

On 2022-02-12 by Trevor Williams

Many thanks for the response. (Apologies: I meant ‘sensible’ cooling rather than latent cooling.) Here’s the larger issue that prompted my question.

We plan on replacing a 5-ton Lennox (HSXB15-060) with a 5-ton Trane XR16. The Lennox unit cooled 3200 sq ft without problems for 15 years but leaked 6 lbs of refrigerant last year.

Wrightsoft sizing calculations indicate that we need a unit delivering about 60,000 BTUh sensible cooling and 6,500 BTUh latent cooling (setpoint 77F). The Trane replacement delivers a little more than 40,000 sensible BTUh’s and so appears undersized. I assumed all 5-ton units delivered much the same cooling output.

If so, how come the Lennox worked so well? OR, does the 5-ton Lennox deliver more sensible cooling than a 5-ton Trane? Is there a lot of variation between nominally equivalent units in the same environment?

On 2022-02-12 by Inspectapedia Com Moderator

@ Trevor Williams

I'm in over my head trying to answer this question but thanks, it's important and interesting.

Older Lennox units that used copper coils may have seen more leakage from corrosion than newer ones (since 2014) that have, like other manufacturers, changed to aluminum. That may be a factor in the leakage your system experienced.

The Trane XR16 is one of the "lower end" (less costly) lines offered by that company and has a SEER around 16 or 17. The Trane XR16-4TTR6061B or 4TTR6060B are its 5-ton rated units rated at actually 60,000 btuh. The Trane XR16-4TTR6061C, also a nominal 5-ton unit actually has a little smaller cooling capacity-actual, of 57,500 btuh.

So if your Trane is a different model, nominally a 4-ton unit, it's not one of those above. See this Trane example 5-ton unit energy guide for the Trane-XR16-4TTR6060B that is actually rated around 14 SEER. https://inspectapedia.com/aircond/Trane-XR16-4TTR6060.pdf

The Lennox HSXB15 series claim SEER between 12 and 15, varying among model sizes, with the -060 signifying a 5-ton unit. The fact that the energy ratings differ might be a clue that the actual field performance may vary, too, for two A/C units of equal ton-rating.

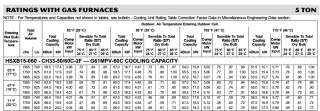

I will attach a chart, just an excerpt from a larger document with more data and not necessarily exactly your Lennox unit, but illustrating some of the variables in the actual cooling capacity of a given air conditioner. You'll see that the cooling capacity is affected by or varies, for the exact same unit in otherwise identical installations, based on changes in the entering air temperature, the air volume or flow rate through the system, and the outdoor air temperature entering the condensing coil.

Given that example it would be no surprise that two 5-ton units from two different manufacturers, sporting different engineering details, designs, specifications, may actually vary in their effective cooling capacity or, as your question puts it "cooling output". Details for your Lennox unit are

in LENNOX-HSBX-15-SPECIFICATIONS

On 2022-02-12 by Trevor Williams

How can I get hold of OEM expanded performance data? The manufacturers websites seem to be password protected. Do all 5-ton AC units have much the same latent cooling capacity?

On 2021-07-14 by Sarah

Thank you so much!

On 2021-07-14 by Inspectapedia Com Moderator

@ Sarah

I want to say yes, or a chicken-hearted "yes if approved by your local plumbing inspector"; candidly: I don't have a sufficiently-clear understanding of your HVAC system nor just what units are producing condensate nor whether there is more than one condensate source (air conditioning vs. a condensing boiler?).

I want to say yes, or a chicken-hearted "yes if approved by your local plumbing inspector"; candidly: I don't have a sufficiently-clear understanding of your HVAC system nor just what units are producing condensate nor whether there is more than one condensate source (air conditioning vs. a condensing boiler?).

It certainly is easy enough to experiment with a temporary close-off of the existing condensate drain when you are in heating mode and assuming you are certain that there is no condensate to be disposed-of in that mode.

I'm unclear what "ball trap" you were considering. But there are "waterless condensate traps" designed for your circumstance, like the SUPCO RLC051 that I show here, available from HVACR suppliers and approved for that use. That ought to end the debate. And it ought to let you find out if the drain is truly the only odor source.

On 2021-07-14 by Sarah

Thanks so much, Dan. Thanks for all your input. Addressing your points:

We have one air handler that serves both the heating and the cooling side. The gas furnace is directly on top of the air handler and the AC cooling coils are on top of that. The furnace has a condensate trap that’s part of the condensate capture system in the furnace itself. The condensate from the furnace collector box and trap empties into a condensate line which is common with the line from the AC unit.

Per info in the link we shared, the AC condensate line experiences positive air pressure because the air handler blows air into it, which we observe at the tap point on the line. That would seem to mitigate the potential for odors intruding into the HVAC from the floor drain where the line empties. On the other hand, during seasons when the AC and furnace sometimes run in alternating cycles there’s an unpleasant odor coming from our vents.

We found that, after much trial and error and multiple visits w/HVAC techs, that we can reduce, if not completely eliminate this odor by making sure the condensate line is extremely clean. This suggests there are various junctures when the air pressure in the line is negative and drawing odors into the HVAC system.

Due to the observations about evaporating water in P-traps, we are wondering if the ball valve promoted in the white paper would be appropriate to our system and would appreciate your thoughts.

On 2021-07-14 by Inspectapedia Com Moderator

@ Sarah

Interesting article and thank you for the question about using a check valve as an alternative to using a P-trap on an air conditioner or heat pump condensate line.

Let's not forget the reason for traps on condensate lines: to avoid sucking noxious gases up into the building air-supply; So we want to trap the condensate drain line at the air handler.

The author does some fun analysis of water evaporation rates and so that leads to a concern that the water in the trap dries and the trap fails; If there's no water in the trap I suspect the air handler isn't being run - so no condensate is being produced - so we're not particularly drawing noxious gases into the building air through its duct system until the system is back on - and then condensate is usually produced pretty quickly.

There are, of course, fancier trap alternatives that will block back-flowing gases using a flapper trap; For floor drains - a similar problem - we simply pour some mineral oil into the trap. I'll look at the article again in more detail.

For other readers who, like me, are reluctant to click on off-site links to whoknowswhere, you can also see this article at by Nicholas DesChamps here at

HVAC, CHECK VALVE ALTERNATIVE to P-TRAP for HVAC CONDENSATE [PDF] (2020) - Des Champs, Nicholas, H., Ph.D., P.E., Fellow ASHRAE, HPAC Engineering, eNewsletter, Web: hpac.com - retrieved 2022/07/23, original source: https://www.hpac.com/piping-pumping/article/21130312/time-to-reconsider-use-of-ptraps-for-condensate-removal

The alternative device described by Dr. Des Champs is, in essence, a ball type check valve intended to permit condensate to drain and to avoid a potential back-up of sewer gases into the HVAC system air distribution (to building occupants), as an alternative to the traditional water-filled P-trap that is designed for that purpose.

OPINION: We agree with Des Champs that there is a known problem with loss of the water seal in traditional traps used on HVACR condensate disposal lines.

Des Champs also cites other advantages of waterless trap alternatives such as avoidance of the risk of freeze-damage and of collection of sludge that can accumulate in and clog a plumbing trap. Those are genuine problems that are indeed well recognized in the industry, enough that there are A/C condensate trap cleanout kits and traps that are designed to be easier to clean and others designed to protect their water seal from loss.

It is worth noting that the article includes some interesting and useful analysis of the rate of loss of water from a plumbing trap - nice work.

It's worth noting, too, that the author's company, DesChamps Technologies, designs and sells the type of product touted by the author, and that's the idea.

We'd have liked the article to have made more clear that if your HVAC condensate is NOT connected to a plumbing vent or sewer line or drain without an air-gap - which by code it should not be anyway - then, where the condensate drain isn't directly connected to building drain piping, the possibility of back-drafting nasty sewer gases up into the air handler through the condensate drain is essentially nil or zero.

We'd also like to see more data on the ability of a ball-type check valve to resist clogging or sticking from dust, debris, or algae that may enter the device from the air handler's condensate pan. Other experts warn about this problem:

"The first and most effective step for avoiding valve failure is keeping the pipeline and valves clean and free of debris. This can be achieved by installing filters and covers where required. Regular flushing of the piping system can also be performed to remove settled debris and minimize the buildup of contaminants." - in "Thomasnet, PREVENTIVE MEASURES TO AVOID CHECK VALVE FAILURES, IN THE ESSENTIAL GUIDE TO PREVENTING CHECK VALVE FAILURE [PDF] (2018) Thomas Engineering, - retrieved 2022/07/23, original source: https://www.thomasnet.com/insights/guide-to-preventing-check-valve-failure/

Please see details about proper condensate drain installation, problems, and avoiding trouble in the article series beginning at

CONDENSATE HANDLING, HVAC - home

and be sure to see also

where we'll ultimately move this discussion.

Thanks again for a helpful question.

On 2021-07-14 by Sarah

Regarding p-traps for condensate lines, can you weigh in on your thoughts about this?

On 2021-07-11 by (mod) - Solving Noisy Roof Top A/C Condenser Vibrations

HVAC system noises are easily transmitted into a building by metal ductwork, pipes, or even the roof structure itself that can act as a giant speaker cone.

To solve noisy rooftop HVAC units including hum and vibration noise the onsite technician needs to

First decide if noises or vibration are abnormal - if normal, use normal sound isolating measures such as padding

For abnormal noises or vibration, trace the problem to its source, such as

A failing bearing on a motor or blower fan

A failing motor

An unsafe electrical condition

Loose mechanical parts or sheet metal or even something as simple as an access door that's not latching

For details see, and give copies to your technician of the following:

- HVAC NOISE-1 BANG BUZZ VIBRATE - banging, bearings, buzzing, thumping

- BANGING A/C or heat pump

- BANGING NOISE at AIR HANDLERS or in DUCT SYSTEMS

- BEARING NOISES in HVAC equipment or motors

- BUZZING SOUNDS & vibration sounds from A/C, heat pump or inverter or from other equipment in, or, or near buildings

- BUZZING NOISE DIAGNOSIS - topic home

On 2021-07-11 by Ballen

Roof Top A/C Condenser Vibrations

I live on the top floor of a 4 story 100 unit apartment building. There are 4 A/C condensers on my roof for the units below and at least two are creating an unbearable vibration and hum.

When the maintenance man went to install vibration pads under the units, I heard two very loud crashes and think he damaged the units even more as the vibrations are much worse. Its sounds like a train in my apartment and I feel strong vibrations when sitting or even in bed. I even have two sets of vibration pads for my bed but it still is annoying.

The mechanical contractors are coming for the third time tomorrow to look at the units but I dont have a lot of faith in them. Looking at there permit history they do mostly kitchen and bath remodels and plumbing and maybe one or 2 A/C installs. Bldg management refuses to hire anyone else.

From researching online I know there are many many possible fixes but I dont think these guys will be open to anything more complicated than more pads or a sound blanket.

Any advice? Another neighbor just went through this and basically gave up but I dont think they had it as bad as mine.

btw should these units be on their own styrofoam/concrete pad. They wont let me on the roof but the set up on my roof section was described as 4 condenser units with each set of two condensers on a pair of 2x6s. There are cheap rubber antivibration pads under the four corners of the units and under the 2x6s. thanks

Question: A/C unit blower motor spinning too slowly, low voltage?

CARLOS I SANCHEZ 4 July 2021

The blower motor on my rheem package unit is spinning very slowly and the my home is not getting any air circulation. i checked the contacting coils and got 120 on top and bottom but didnt get 24 volts in both the middle contacting coils. notice that the condenser was freezing up due to the fan not blowing as its suppose to. checked speed 1 and 5 and i was not getting 24 volts there as well. what could it be?

my rheem package blower motor spinning slowly and i am not getting any air circulation in my house and notice the u it freezing up in the coils and compressor. what could be wrong?

Moderator reply:

Loose connection, low supply voltage, failing motor, loose fan belt or pulley, or something else

Starting at

AIR HANDLER / BLOWER UNITS - home

you'll find a series of air handler / blower unit diagnostic steps

Also

See BLOWER FAN OPERATION & TESTING

See ELECTRIC MOTOR DIAGNOSTIC GUIDE

Question: a lot of condensate coming of condominium A/C - normal?

Marietta habbershaw 1 July 2021

My condo's a/c is dripping 5 gallons of water in 12 hours! Is this normal?

Also my downstairs is cool and upstairs is blazing hot! Az is no joke in the summer!! Where should I even start?

Moderator reply:

That might be normal depending on the total volume of area being cooled. You might compare your condensate rate with your neighbors who have similar size and similar cooling settings on their thermostats. If there's something unusual going on I would be looking for a water or moisture source in the building.

Reader follow-up: upstairs is not getting cooling

What about the upstairs feeling like a heaters on while downstairs is nice and cool?

Moderator reply:

When we try to answer questions like yours the stumbling block is that we don't know a thing about your building, size, construction, installed equipment, etc. so new data can always change the direction of our advice

If your upstairs is hot and downstairs is cool

- is there only one A/C system or are those separate units?

- If only one system, then the duct system is un-balanced, loose, blocked, disconnected

- If two systems, the upstairs one is not working

THEORETICAL EXAMPLE:

If the upstairs return duct system is open to and drawing in hot humid attic air then it'd overload the 2nd floor cooling system and as there's an infinite supply of outdoor hot humid air that'd produce a LOT of condensate

Reader follow-up:

Thank you, it's one olllld unit, about 1100 Sq ft condo... I'm now thinking my son put something in the vent because we can hear everything in the house from master bedroom. I'm going to use the snake camera and take a peek in the ducts! Once again, thank you, it's awesome there's people like you out here helping us that are desperate to not call the expensive repair guys!

Moderator reply:

We're glad to assist

but

keep in mind that no one an be as clever by text as an onsite expert - there is always something that an experienced onsite technician will or ought to see that may not have occurred to a homeowner to mention.

Keep us posted; working together makes us smarter.

Question: - stains on A/C unit drip tray - are these a mold problem?

Anon: June 18, 2021

I keep trying to upload a photo from the rear edge of the drip pan tray when coils were replaced but it won't upload. It's a JPEG and according to the note that keeps popping up, this is one format that should work, but it doesn't. Any ideas how I can get a pic to you?

Moderator reply:

I'm not sure what happened, Annon, but I checked with the moderator page and I did not find your original message nor image waiting for approval.

In general the process is easy: type in the comment box, and click the image icon to add an image.

Then click the gray "Post as ..." button at bottom right of the comment window.

But in any case I'm sorry you're having trouble posting an image.

You can send email and images to us directly using an email that you will find at the page top or bottom contact link.

At ODORS in AIR HANDLERS & DUCT WORK

you will find our email discussion on tracking down ductwork odors and also your photo.

Question: track down source of A/C duct odors - deteriorated materials?

2021/06/04 Annon

I’ve posted about this problem in the past and writing an update in the hopes you can provide additional guidance.

A couple of years ago, during the seasonal transition from winter to spring when weather fluctuates and we move back and forth between heat and ac, a smell came up through the registers when we turned the ac on after it had been off for a few days when heat was used. The smell was like a sweaty locker room and only occurred when using the ac after the back and forth from ac to heat and ac.

We had multiple checks of our HVAC system by HVAC techs, senior techs, managers, and a manufacturer representative. No one was able to figure out what’s causing it.

We also consulted with our IAQ/mold expert who hypothesized there’s at least one place where water sits and something starts to grow (mold? bacteria? etc…). She also observed discoloration along the front edge of insulation which we removed, even though she couldn’t definitively say if it was mold.

Other than that, no one saw anything of concern. In fact, HVAC techs comment on how clean our system is. We also had our ducts cleaned a few years ago after we bought the house and were told our ducts were very clean.

When I posted about this a year or two ago, you suggested cleaning the coils, which we did using a product in a spray can that the HVAC tech said is approved for use on our system. After cleaning the coils, the odor was eliminated, but then it returned after we switch btwn ac and heat and then ac again.

Per your suggestions from last year, we’ve had the air handler inspected. Multiple times. No HVAC tech has ever seen anything of concern

. The blower fan has also been checked and it’s clean with no suspicious marks of any kind. We change our filter our regularly (more often than recommended because we’re mavens about indoor air quality).

The duct work has been cleaned, but I don’t think they used cameras to inspect. However, if there was mold contamination in the ductwork, why would the smell go away after we clean the coils? It’s hard to imagine that the spray cleaner would be strong enough when running through the system, including the ducts, to kill any mold, but maybe. Let me know your thoughts since cleaning the coils is new info since my last posting in 2020.

Of note, our furnace is gas and we don’t have a heat exchanger.

One HVAC tech said this shouldn’t happen w/a gas furnace because the heat should kill anything that starts to grow. Numerous furnace checks showed the heat reaching the requisite 127 degrees where the air leaves the furnace.

Also, we routinely check and clean the drainpipes and are confident they’re not the source of whatever is causing this odor.

The fact that we can’t smell the odor with the heat suggests that whatever the cause, the heat kills it, but then once the AC comes on, it’s reignited. To my mind, this suggests mold, which dies leaving spores behind that can come to life again once wet. And although “dead” they may still be releasing toxins.

Our IAQ person thinks that perhaps when the AC is running constantly in warm weather months, the condensation keeps things moving and there’s no time for water to sit, but when the system is turned off for a short while, water is collecting somewhere.

A couple of weeks ago, the HVAC company replaced the coils (which were relatively new from being purchased a couple of years ago).

When the coils were removed, there appeared to be efflorescence on some of the aluminum backing of the insulation in the casing.

We also observed a gray discoloration on some of the fins on the coils which you could only see from underneath once they were removed.

There was also tiny black spotting along the rim of the pan under the coils that faced into the casing (so unfortunately, w/o removing the coils, we can’t monitor that location right now). I tried to attach photos, but was not able to because apparently they're not in the right format (jpg).

At the same time the coils were replaced, we also had the induction motor and collection box in the furnace replaced. The reason for replacement was an old motor and the HVAC tech observed a crack in the collection box which he said is a common problem, while noting that water could leak out of the crack. And we could see that some water had dripped out of that part at some point as we observed water marks.

Since the day they replaced the coils in mid-May, we’ve transitioned from ac to heat. Then yesterday, when we transitioned back to ac and the smell returned. So we cleaned the coils again and now the smell is gone.

We’re wondering if we should have the entire system taken apart in order to do a complete inspection. Perhaps the insulation is the source, though we can’t figure out how the insulation could get wet. But you never know if it was brought in with an area that was wet when it was installed. Who knows? That said, we can’t imagine how cleaning the coils which seems to have a beneficial effect, would impact insulation.

Related to things we’ve considered but seem unlikely is the line that’s the exhaust for the gas furnace. We tried looking down it from the outside, but since it turns, we can’t see very far and don’t have a camera. We could have our IAQ person put her camera down the line, but again, like the insulation, it’s hard to imagine how coil-cleaning would affect this component.

What would you suggest as a next step for this problem that seems to have everyone stumped?

Thank you for taking the time to read this length update and providing suggestions on what to do next.

Moderator reply:

before tearing anything apart why not have a camera inspection of the duct system?

Reader follow-up:

Yes, we're trying to find a reputable company to do that. Thank you. Meanwhile, our current HVAC provider is suggesting we coat the coils with epoxy and said they routinely do this in the south (I presume because of high humidity issues). Ever heard of that? They have no real scientific evidence to back up that approach and our gut reaction is not to go down that path.

Would be curious to hear your take on it. Also, a brief update: When we cleaned the condensate line last week the smell greatly improved. It's a bit odd because we, and the HVAC techs have done that in the past but it never seemed to help. We're also a bit mystified as to how something growing in that line (which we routinely clean) could pull back into the system as it seems like it should only exit, no?

Re: duct inspection. Our IAQ consultant said that when using borescopes (even high end ones) it's very difficult to be able to steady them well enough to focus on very small things. She doesn't anticipate any significant mold issue (if any at all), so it would mean very small close work and she's skeptical it would be helpful.

Also, just a reminder that when the smell is there (only during season transitions when we don't use the AC every day), it comes out of all the registers, which would suggest that if there were a problem in the ducts (or any other problem within the system) that it's something central, no? (I keep trying to upload a photo but it won't let me, even after I changed the file format to one of the required formats to upload. Very frustrating. FYI.)

Moderator reply:

The odor might be mold or it could be something else getting picked up in the return duct system or even near a return register .

But when cleaning the coil knocks down the odor that suggests an odor source in the system; when odors return the problem could be a new entrapment of odor materials (mold or ?) on the cooling coil from another source in the system, most-likely on the inlet side of the cooling coil: that means maybe looking with care at the return duct system, filters, etc.

I agree that borescopes give a very limited view of anything.

I wasn't suggesting a borescope.

If an inspection of the ductwork doesn't show anything suggestive but if as well not all areas are accessible and more so if the ducts are insulated on the duct interior it's worth a more-careful look before tearing things apart.

An inspection camera is a different device sent through ductwork, providing light and a wider view. These are widely used in HVAC ducts as well as in piping systems, but

Watch out: don't let anyone run a sewer line camera into your ductwork - it's the right kind of camera but if it's been in a sewer .... well you get the point.

And we're not looking for a few tiny particles - of anything - those would not be significant.

Reader follow-up:

Thank you. As always, your input is all very much appreciated and highly valued. We will pursue and focus as you've suggested. With gratitude.

On 2021-04-22 - by (mod) -

@Okeefe,

That's an interesting legal question, not one I can answer (I quit law school early).

I pose that an attorney would look at the age of the installation, the original contracts for work, any warranty terms, and she'd also want an opinion from an independent expert on exactly what failure has occurred and on its cause.

On 2021-04-21 by Okeefe

In Florida...If an AC system line set is underground and leaks are detected, who is accountable for repairs? The homeowner or the builder? Possible cause is water in the pvc causing copper to erode? Thanks

On 2021-04-18 - by (mod) - rooftop unit is not turning on

@dali H ,

You could try changing the fuses but if they blow again then you've got a seized motor or a short circuit and you need to leave the circuit off

On 2021-04-18 by dali H

Hi, and thanks for answering. The thermostat works when turning the fan and the heat. I could not adjust the temperature lower than what it is inside. The override only works for adjusting the temp up. I therefore just tried the heat option. It turned on inside the house, but it only produced room temperature air.

I checked the unit on the rooftop and nothing was moving. I think the unit on the rooftop should be working even when turning the heat on, right?

I looked at the fuses in the power box, or whatever that box attached to the unit on the roof is called, and they look a bit blackened. Again I don't know if that could be the problem or not. Thanks again and have a good evening.

On 2021-04-18 - by (mod) -

@dali H,

It sounds as if your rooftop unit is not turning on. I can't tell from your text if that's something as simple as a disconnected thermostat wire or whether there's a bad control or whether a motor or compressor has failed.

In the article index take a look at the link to

LOST COOLING

Where you will see some basic diagnostic steps many of which can be completed by homeowner.

On 2021-04-17 by dali H

Hi, I have a payne HVAC system. When I turn on the thermostat (it has a switch for heat and cold and another one for a fan) to either cool or heat the air blows but is neither hot nor cool (I also turn on the fan at the same time). The unit on the roof does not engage, that is I hear no noise and the fan blade does not turn. What could be the problem? I preface that the unit is quite old, although I haven't used it much as I live in Los Angeles closer to the ocean. I would appreciate any ideas you might have. Thanks

On 2021-03-23 7 by (mod) - Why does my fan keep running when the unit is turned off

Thank you for the post, Rachel

Dorothy:

If you are asking about the cooling fan in the outdoor compressor/condenser unit for your air conditioner or heat pump, see the diagnostic suggestions

at FAN, COMPRESSOR / CONDENSER UNIT DIAGNOSE & REPAIR

If you're discussing the indoor air handler fan ,take a look at the diagnostic suggestions

at A/C or FURNACE FAN WONT STOP

On 2021-03-23 (mod)

RE-posting without advertisement

Rachel said:

@Dorothy Spencer, It may be the clutch bearing in the air conditioner pump is worn out. This part has not been replaced. The air conditioning pump needs to be replaced.

On 2021-01-18 by danjoefriedman (mod) - Why does my fan keep running when the unit is turned off

Dorothy

I think you're asking a question about a heating system not a more cooling system. It's normal for the blower fan to run for a brief time at the end of the heat cycle to purge the remaining heat in the air handler. That avoids the risk of overheating and cracking the heat exchanger which would make heater unsafe.

If you search this website for the phrase

Blower fan continues to run after a call for heat

Then you will see the details

On 2021-01-17 by Dorothy Spencer

Why does my fan keep running when the unit is turned off.

On 2021-03-19 - by (mod) - find and fix the refrigerant leak

@Jim Navotney, thanks for the comment

@Jim Navotney, thanks for the comment

I agree with you. With some service technicians will claim is that they have so much trouble finding and fixing the leak that their customers actually prefer the much lower charge of Simply delivering refrigerant periodically. One could add to your comment that it is both illegal and an unfortunate contribution to environmental damage to keep leaking refrigerant into the atmosphere.

The correct fix, as you so emphatically state, is to find and fix the refrigerant leak.

On 2021-03-19 by Jim Navotney

Systems leaking refrigerant over the winter is a common issue and most techs won't fix it because a recharge is a revenue generator and a easy service call.

The tech i called was here for 15 minutes and charged $400 to put in 6 pounds of R410A which had leaked out in about 6 months time.

So as soon as he left it kept leaking as before and by the end of the season it again needed charged.

Despite much bad information on youtube and the web, most leaks occur at the service valves.

This is because the schrader valve is dry rotted or was damaged during the install or servicing.

While replacing the high and low side valves would be the best fix, merely buying "o" ring service valve caps can slow or even stop small leaks.

The King valve caps can also leak and "O" rings can also be found for them.

My leak detector confirmed low and high side service valves leaking and after installing the "O" ring dust caps, the leak was no longer detectable and the system has been holding charge.

On 2020-09-15 - by (mod) -

I'm so sorry Amber, but generally you need a trained HVACR repair technician to fix an A/C unit if the obvious checks that can be done by a homeowner are fruitless.

Once you've confirmed that the power is on to the equipment and that the thermostat is set to COOL and is set to a temperature well below existing room temp, if the AC won't run a tech will need to check the control board, relays, and possibly refrigerant charge; that requires both training and special equipment.

On 2020-09-14 by amber mac

i recently moved to a home with an hvac heating and cooling setup, which ive never had the pleasure of having. anyways , all summer my air conditioner hasnt worked. the house sat empty for 2 years but the furnace works and kicks on . i have an air temp type central air conditioner that sits outside.

Im sure the weather may have something to do with it . ive tried the breakers, fuses, thermostat, checked all incoming electric and all are working.

It simply wont turn on, i know its not the fan because it turns and the bearings are good. on the control board mounted on the upper side of the unit , the led light is flashing 6 times, repeatedly. i troubleshooted online and it says it could be the blower motor amongst other diagnoses that we have tested. i also reset the system, breaker, thermostat and still nothing.

However, im not sure the air filter is clean , but ill check that next. does anyone have any suggestions or advice because i cant call a specialists because its wayyy too much money. has to be done by my husband and i . any help is appreciated ! thanks !

On 2020-08-11 - by (mod) -

THanks for the helpful comment, Aaron.

On 2020-08-10 by Aaron Addison

A wonderful resource for repairing AC unit. If you really want to save your AC unit free of dust, bad weather and from other issues then first dedicate a proper space for outer unit and also keep maintaining it for better performance from experts.

Experts can really takecare of your system to increase its lifespan. Lastly, buy energy effecient units of a reliable brand for better results and maximum cooling.

On 2020-07-29 by Piston housing leaks

Having trouble with Goodman evap sealing piston ring. Keeps leaking even when very tight.

On 2020-10-12 by (mod) - residential air conditioning industry construction standard for the supply duct downstream (i.e. located after) a refrigerant coil

DUCT SYSTEM DESIGN SIZE & DEFECTS - home - includes in the references section of each of the pages in that article series, citations of codes and standards.

You're right that good HVAC duct design usually provides an adequate main trunk to give velocity and volume to the conditioned air before it's branched off into individual distribution lines. hvacsales.com says that

"... the minimum recommended plenum size would be -- width: 2 x 16 or 32 inches; length: 1 x 36 or 36 inches wide. The depth of the plenum is always the same depth as the supply trunk."

On 2020-10-11 by AlexEnergy5

What is the residential air conditioning industry construction standard for the supply duct downstream (i.e. located after) a refrigerant coil. ?

If there are flex ducts that are installed on top of the refrigerant coil, wouldn't that be an inappropriate location to achieve full airflow from the cooling coil? Commercial air handling units have at least 12" - 18" from the fan discharge to the opening of the supply ductwork.

On 2020-09-29 - by (mod) -

Still that could be badly-burned contactor points that just make no electrical contact.

A service tech will check for power at the control board.

On 2020-09-29 by Michael moreno

I myself have the same issue my contractor does engage but my new condenser fan motor does not turn on the contactor is pushed in but nothing

On 2020-09-08 - by (mod) -

Difficult to answer because I'm not sure which relay is giving you trouble. It could be an improper wiring problem or a control board problem or even wrong relay.

On 2020-09-08 by Nabi

What is the cause of relay contact switch not coming on. It is new part, Could it be low on refrigerant?

On 2020-08-14 by Mario

So a/c tech found a leak on the liquid line right before it went into the coil box.

So a/c tech found a leak on the liquid line right before it went into the coil box.

All working now, but I'm worried about long term impact of using 5 ton coil with 4 ton condenser. Not too happy about the piston vs TXV as far as efficiency but at this point I doubt I could get the home warranty company to swap it out. Thanks.

On 2020-08-14 - by (mod) -

Mario

An air conditioner won't work without some sort of refrigerant metering device, either a TXV (Thermotatic expansion valve) or a capillary tube.

On 2020-08-13 by Mario

I had Lennox coil (CH3349C with TXV) replaced with ADP/Armstrong (A60H210P196 with piston) coil. Ever since it has not worked properly, takes hours to cool, from 75 to 70 even late at night, when its not fighting the high outdoor temps in San Antonio.

The condenser is Carrier 24ABB448A3, its a 4 ton, and never had any issues with cooling the house - 2story, 3000sqft.

Most likely cause(s)?

1. Lack of TXV on new coil, since it was on the original Carrier/Lennox setup. (The label literally says TXV installed but the repair company can't explain why it was removed.)

2. Improperly sized piston

3. Coil - Condenser mismatch. I know there times where a coil upsize might be called for but wasn't before replacement. The condenser model doesn't show up on AHRI so I haven't been able to check compatibility, 4 ton condenser - 5 ton coil. Would the larger coil reduce CFM and require adjustment to the air handler?

Thanks for any feedback on likelihood of causes I listed or any other potential ones.

On 2020-08-11 - by (mod) -

Max

I really would like to help but I don't understand the situation that you described.

A return air vent would not normally be cold. Are should be leaving the room and going back to the air handler through that opening. So I'm a bit confused.

On 2020-08-10 by Max

I need some help diagnosing my AC problem. The blower in my Lennox unit seemed to stop kicking on. The compressor will work when I flip the breaker and try to restart. The refrigerant also seems to be pumping, because the return vent is very cold.

Before I noticed the problem the coils also seemed to freeze up. We thawed out the system, drained the line. But when I turn the system back on the thermostat clicks, the refrigerant pumps, the compressor kicks on, but the air handler doesn't turn on anymore.

I took off the panel and got a message that there is no communication with the indoor blower. I also replaced the thermostat batteries and there doesn't seem to be any glaring issues with the wiring.

Lastly, when I turn the system off it makes a hissing noise and kind of a light crackle before shut off. Any help diagnosing what the problem might be?

On 2020-08-11 - by (mod) -

Lynne

Refrigerant is odorless. I'd look for an odor source near a return air inlet or for a spill or leak into the air handler or duct system

On 2020-08-10 by Lynne

Help, help, help (please). In May, I had to replace the compressor and air handler for my 20 year old high velocity AC system. They installed a variable stage Bosch and Unico air handler.

The ductwork remained the same. It's been a nightmare. I am getting a sour, acrid, vinegar like smell coming from the system. It's a heavy odor, it settles on everything and permeates bedding, clothing, paper products, towels.

It seems to be worse when the system first comes on, and when the variable compressor is running at a lower speed, and not quite as noticeable as when it's running full power. But as it cycles off and on I am getting full blasts of this horrible smell.

The contractor came out and cleaned the coils and checked the drainage, and everything looked fine, but the smell is still there. There is also an IWave air cleaner in place.

We tested removing it, it's not helping or hurting. Any ideas on what would be causing this? Would a duct cleaning help? Can you clean the small high velocity ducts? I would be so appreciate of any info. Thank you.

I'm starting to think this is a pinhole leak at the air handler coil, and what I am smelling is refrigerant. Any ideas?

On 2020-08-03 - by (mod) -

That looks like several kinds of mold growth - seriously contaminated and badly in need of cleaning.

That looks like several kinds of mold growth - seriously contaminated and badly in need of cleaning.

See SPLIT SYSTEM AC MOLD CONTAMINATION REMOVAL

On 2020-08-02 by Chesley

How to tell if dealing with mold in air vents of home?

On 2020-07-20 - by (mod) -

Elrod,

That post mortem would be both interesting and helpful to others, so if you do it, please tell me what you find.

On 2020-07-20 by Elrod

Thanks, I had two other opinions this morning that offered the same thoughts, because of the vertical play. Except one thought it was probably electrical (position relative to brushes) and not mechanical (binding) because the effect was worse when under power.

I might keep the motor and eventually do a post-mortem autopsy on it to find out for sure (but this is definitely low priority for the near future).

Either way, the consensus seems to be the motor has reached its EOL, being more expensive to rebuild than to replace.

Now, if I can just be successful in removing the STUCK fan blade from the shaft (even a gear puller didn't help, was just bending the fan flange our of flat -- I see more work ahead of me for that).

My appreciation for your taking the time. Maybe several of us learned from this. Stay safe.

On 2020-07-19 - by (mod) - diagnostic steps lead to bad fan motor or bearings

Elrod

That's an interesting and helpful series of diagnostic steps you tried. I suspect that the fan bearings are shot, so when the motor is in proper position the shaft is binding.

On 2020-07-19 by elrod

I have a very old (>27 years) RUUD a/c with an emerson 1/3 HP 4-wire PSC motor. A few days ago I noticed the fan was not running outside. Fan would not spin easily with a stick with power on or off. Decided fan motor must be bad.

Took it out, still wired. Upside down, spun it easily by hand. Put circuit breaker back on; fan motor humming loudly; so decided motor OK, but start capacitor was bad. Got one next day and reassembled. No improvement.

Pulled fan motor out of cage again. Still wired, upside down on top of unit. Now with power on, I COULD spin it up and it seemed to operate OK. Tried putting it back right way. Now, nothing. Checked circuit breaker again.

Two pole 60 amp Square D; one side open in either position (I remember replacing circuit breaker about 25 years ago). Had to order, so another day gone. Got it yesterday. Now fan started itself when AC powered (but still upside down on top of unit), so I figured it was fixed with new capacitor.

Reassembled, fan now in correct position. Back to not starting itself, plus powered fan difficult to turn again, humming loudly. Started checking all wiring, turning fan over, etc. Managed to pull couple wires loose. (Previously, they didn't seem to match all the on-line help about how to wire.) Think I got all back where they had been when it was working in past, but not positive.

Long story shortened -- fan works way it should when it is upside down; sounds like it is fighting with itself when right side up.

What gives? Also, noticed a little up-down play in shaft, but none side to side.

On 2020-07-08 - by (mod) -

I"m not sure, Tommy; it may be a control failure developing;

On 2020-07-08 by Delco Tommy

I have a Samsung mini split heat pump.. When turned on,the fan blows at an especially high rate (RPM) for about 10 seconds then the unit shuts down...doesn't happen all the time,sometimes it blows normal and cools the room,but it is intermittent and untrustworthy.Any hints to a possible problem?

On 2020-06-28 - by (mod) - possible refrigerant line crimps & connection defects?

On 2020-06-28 - by (mod) - possible refrigerant line crimps & connection defects?

If the refrigerant tubing is bent enough to be damaged, creating a stress point, it may break - leading of course to a system failure; If it's bent enough to be significantly obstructed, I'd agree with your Dad that on the suction line we might trap oil.

I can't say how severe the damage is from your photo.

In general we want some slack, a loop or more, on both the high and low refrigerant piping lines at the compressor, as a vibration isolator and to avoid damage and leaks that will be caused by even the slightest movement in the unit.

So having a curve or bend is by no means a mistake per-se. In fact the original "bad" installation had, from what I can see, better refrigerant line routing and connection than in your "improved" photo.

I'm including an excerpt of your photo here to invite other readers to comment.

Indeed on looking more closely, the larger diameter joint looks iffy and the smaller line is rather crimped.

Might want to replace those - it's not cheap to do; you'd have to have to evacuate the system, modify the piping, then recharge the system.

On 2020-06-28 by 1yr old Bryant Central air making loud piston noise

Hi. I have a very intermittent issue. About every 2 weeks, and all 4 times it's occurred it was during the hottest part of the day.

Turning it off waiting a few minutes and back on resolves the noise for a few more weeks.

Turning it off waiting a few minutes and back on resolves the noise for a few more weeks.

I let it make the noise for a minute without shutting it off and video taped it.

I don't want to skew your diagnosis but I would be remiss if I didn't explain one thing.

The installer did one of the worst installs I've ever seen and I got very angry and made the owner of the company come over and re-install it correctly.

The initial install had the unit turned the wrong way.

Pipes away from the house and exposed and prone to lawn care damage. And it was tight against the house blocking one side airflow. Here is a picture of the bad install.

When they re-installed it.

They mounted it up on rails and away from the house. Here is what it looks like now.

Much better. And plenty of airflow and correct orentation. However.......

The low pressure pipe has a bend in it rather than going straight into the house. This was due to the bad initial install.

My dad said the bend could be be resulting in oil in the bend and blocking the flow? Again I don't want to diagnose for you. But it could be a critical to the reason.

Here is a picture level on from the ground so you can see the bend.

Than you for any help you can provide.

On 2020-06-25 - by (mod) -

Wayne

Please try to be on Page search box and search for

CAPACITOR SIZE DETERMINATION for ELECTRIC MOTORS

And you will see some tables giving typical capacitor values that we might use as a starting point if we have no data about a motor

On 2020-06-22 by Wayne

Need to know what type of compressor, fan capacitor is used. Unit installed 02/1989

On 2020-06-16 - by (mod) -

If a heater is not listed and approved for mobile home installation, modifying it would be IMO unsafe.

On 2020-06-11 by LISA

Can a goodman AVPTC49c14 be installed in a doublewide mobile home.

If so would anything have to be modified?

On 2020-05-09 - by (mod) -

Ben

A pressure gauge measures pressure, not temperature, so I'm confused. Sorry.

Also, depending on where one measures pressure, HI or LO side, we get different readings and conditions.

Low pressure alarm may be on the suction side - for example.

Finally: Watch out about working on your AC system if you're not trained - losing refrigerant or contaminating the system are risks.

On 2020-05-04 by BEN

HI,got an AC thats indicating low pressure as an alarm after every 12 hrs,when i use the pressure gauge to measure the temperature its ok.

On 2020-04-26 - by (mod) -

David

In our LOST COOLING CAPACITY article in

the ARTICLE INDEX you'll see some easy diagnostic steps that are a good place to start.

We want to check out some obvious things (like is electrical power lost?) before calling for repair.

On 2020-04-26 by David Heckman

Our 4 ton Franklin Model ASTP47C14BA A.C unit quit cooling.. It is only five months old The fan runs and the controls work. Suggestions?

On 2020-04-13 - by (mod) -

Karm

I would not try to fix a fan no-start problem with a larger fan motor, because the underlying problem remains. I'd look for the trouble source:

- bad wiring

- bad control or control relay

- bad start/run cap (or mistake when installing new one)

- failing fan motor

- low voltage

and other diagnostics in the articles I suggested.

On 2020-04-13 by karmika1586

Can a larger fan motor (1075 1/2 hp) be used to replace this 1/3 hp 825 . i serm to be having problems with fan.

If motor is bad. I may need it replaced. The service co. Has the larger motor avail. Or I need to order one.

The 825 is less common and I may have an isdue waiting to get that esp. Now n amazon will be halting shipping...

On 2020-04-13 - by (mod) - HVAC unit fan won't start

Anon:

Anon:

Here are three HVAC fan diagnosis and repair articles that will guide you through diagnosing and fixing an intermittent condenser fan problem with intermittent fan failures.

Before getting too detailed, check for

- a loose or corroded wiring connection

- a bad fan control relay

then see the diagnostic suggestions at

FAN, COMPRESSOR / CONDENSER UNIT

and

ELECTRIC MOTOR DIAGNOSTIC GUIDE

and also, though it's for the indoor handler, see the additional fan diagnosis at

FAN WON'T START

Let me know what you find as that may permit further suggestions and also may help other readers.

On 2020-04-13 by Anonymous

5ton trane condenser. Fan motor is intermittent. Condensor short cycles because fan doesnt start. Can be pushed to run.

Recently put new thermostat. Wired like old one which was instslled with old unit. Not sure if there was a heat pump. ..but this unit has heat pump. Red wire to R & JUMP PIN to RH. Is this a problem with internal circuit board in condensor/ heat pump. And causing conflict in signals? Just had service to condensor.

Oiled/ lubed fan shaft bearing - fan is still squeaking on start up. Til it warms up a bit

Put in new capacitor. As well as new thermostat. What else could be causing intermittent issues with fan.

Rough starts /push blades to start after its off for awhile. Can run fine 1-2days ( hi80°s) then fan fails AGAIN? AC been on for 1 mo.

These issues been going on 2 wks. Even after the new parts. Never sure if fan will start

On 2020-01-24 - by (mod) - Amana RHD60A2A heat pump rebuild?

Reybo

What was included in "replaced the condenser" ? The whole condenser unit? That would have meant a new compressor, fan, condensing coil & controls.

So we'd not expect a new system to trip the breaker if the setup is properly wired and fused. And you'd not install a starter kit on a new AC compressor motor.

On the other hand if you're using an old compressor motor and it's tripping the breaker, a hard start kit might get it going for a time but you've already been warned that the compressor is at or near the e nd of its life.

Indeed commercial compressor motors are often re-built.

But nobody rebuilds residential A/C or heat pump compressor motors. The compressor is in a hermetically sealed can and is not repairable.

You might find a used unit but I'd be pretty reluctant to try that. Few people will remove and salvage an old A/C or heat pump that's still working acceptably, so a used residential compressor on the market is risking having to do the job over multiple times- at a cost greater than having replaced the unit with a new one in the first place.

On 2020-01-24 by Reybo - Amana RHD60A2A heat pumps

This is 2020. We have a 1996 Amana HUAC system. Last summer running the AC it began popping the circuit breaker once a day or so. Re-set and all was fine for a day until it popped again. We had service in and he replaced the condenser and at my request, installed a starter kit.

That almost ended the problem but not quite. So on a hunch, I set the electronic thermostat to wait 500 seconds before re-powering the AC after it shut off, adding about 150 seconds to the old setting.

So far, that worked. Maybe someone can explain why, and if something else needs replacing? And maybe someone can tell me who re-builds Amana RHD60A2A heat pumps? 2020 is the last year for legal freon, and there's no way we can afford to replace this system. We're pensioners on a shoestring. Re-build or find a less used model is all we can do.

On 2019-06-07 by (mod)

Watch out: Rich; when a fuse keeps blowing there is either a short circuit or a seized motor that's drawing so much current that the fuse blows or circuit breaker trips - to prevent a fire.

Leave the A/C off and call for repair.

On 2019-06-07 by Rich

My 3A fuse keeps blowing when turn AC on?

On 2019-01-29 - by (mod) -

Fred

Good practice when brazing A/C refrigerant piping includes

1. evacuate the system and pull a vacuum

2. do the brazing

3. evacuate and pull a vacuum again

4. Install a filter dryer on the suction line, possibly two.

5. Change out that filter dryer after a year

Debris from oxidized copper and flux inside the braze is unavoidable, so those steps are important.

On 2019-01-28 by Fred G

What would be the expected result of brazing on the liquid line connection while the system is charged with R410? Contractor claims he pumped out the refrigerant and replaced it, but I doubt that he did so.

Five years later the filters are so clogged the hot gas off the muffler is at 80*F (shows a 40*F temperature drop across the muffler). Was this predictable, and if so, what could have been done to prevent it?

On 2015-06-24 - by (mod) -

If the condenser never stops and the thermostat is not calling for cooling then I suspect a relay or control board failure. Time to call for service.

On 2015-06-24 by Joe

My air handler turns on at thermsat,but condenser not turning on?? Has line voltage pushed relay to run unit..it's cooling properly,and air handler shuts down at desired temp,but condenser still running and not shutting down from thermsat. ..can I damage unit by leaving it running when air handler shuts off..

On 2015-06-23 by Michael Besupre

Outside fan runs but no cool air inside

On 2015-06-16 - by (mod) -

Sounds like an overcurrent such as from a failing compressor or relay.

On 2015-06-16 by Rafael Pagan

Problem is that I have an ac heat pump system with Outside condenser and Inside air handler. Once I lower the room thermostat to call for cooling (lower than the room temperature) the breaker for the unit on the main box trips and shuts down.

On 2018-12-17 by (mod) -

Ok Josh. Keep me posted. Also I'd like to see photos of the duct interior.

On 2018-12-17 by Anonymous

Thanks Dan, I work in the plumbing department of a MEP company.

Hoping the boys in AC can help me out as I have no clue about duct work.

On 2018-12-16 by (mod) - replace badly-rusted metal HVAC ductwork

Josh If my HVAC system had ducts in such poor condition, I'd replace them. And I'd want to find and fix the sources of crawl space moisture to reduct the mold and other damage risks therein.

On 2018-12-16 by Josh

Went into crawl space to investigate cause for two hot rooms. I found it.

Main supply duct has at least two large leaks and is quite rusty. I’m guessing the ducts weren’t replaced when the system was updated from swamp cooler.

The supply trunk that main sits on is sagging from weight as well. How do I fix this? New main supply and replace rusted trunks?

On 2018-12-12 1 by (mod) - blower won't turn off

Jonathan,

Before replacing any parts you might want to take a look at the diagnostic suggestions found in our article titled

Blower fan won't stop

That you can find in the ARTICLE INDEX on this page

On 2018-12-12 by Jonathan wilson

My blower will not shut off...should i change the blower relay,or the ""high speed"" blower relay?

On 2018-11-27 by (mod) -

Anon

Heat pump system consists of two major assemblies Outdoors a compressor condenser unit and indoors is an air handler that also contains a coil that either heat or cools air blowing across it depending on whether you are in heating mode or cooling mode.

On 2018-11-27 by Anonymous

Where would a heat pump usually be located ?

On 2018-11-18 by (mod) -

I'm not sure, but it sounds like a bad relay or bad connector or bad control board.

On 2018-11-17 by baig

heating contactors making noise suddenly a - blast like noise now like fan touching something - we opened the contactors it is westing house - all intact so we closed it back - the noise is still there - now not running the heating

how to handle

On 2018-11-10 by (mod) -

Rob

Rob

Heat pumps use outdoor temperature sensors for several purposes including switching the compressor motor OFF and switching to backup heat mode if outdoor temperature falls below the safe (or efficient) operating temperature of the unit (typically around 25-30 degF for most units).

An air conditioner unit, that is one that ONLY provides cooling, again depending on age and model, may NOT have any such outdoor temperature controllers.

Such units should be left turned off in winter. If some fool tries to turn on the air conditioning at the indoor thermostat and if the outdoor unit runs in freezing weather it might be damaged by liquid refrigerant slugging in the compressor.

THose AC units do often include a crankcase heater to prevent liquid refrigerant slugging; that's why we leave power to the unit ON for 24 hours before actually asking the compressor motor to run at lower outdoor temperatures.

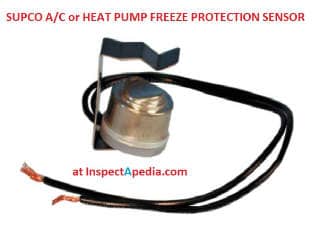

There are also "freeze protection kits" from Amana, Goodman, Supco, and others that provide an outdoor temperature sensor and that prevent the compressor from running at low outdoor temperatures.

Those can be retro-fitted to an A/C (i.e. not a heat pump) if needed. There are similar protection devices that can be fitted at the indoor coil to detect coil icing or freezing in that location, like the Amana FSK-01A kit.

Shown above SUPCO freeze protection switch, opens at 35 degF.

On 2018-11-10 by robinsoninspections @gmail.com

Do any AC systems have an ambient temp safety sensor that wont allow to compressor to turn on below a preset outside temperature?

On 2018-11-10 by robinsoninspections @gmail.com

Do any AC systems have an ambient temp safety sensor that wont allow to compressor to turn on below a preset outside temperature?

On 2018-11-10 by (mod) - freeze protection for heat pumps and air conditioners

Rob

Heat pumps use outdoor temperature sensors for several purposes including switching the compressor motor OFF and switching to backup heat mode if outdoor temperature falls below the safe (or efficient) operating temperature of the unit (typically around 25-30 degF for most units).

An air conditioner unit, that is one that ONLY provides cooling, again depending on age and model, may NOT have any such outdoor temperature controllers. Such units should be left turned off in winter. If some fool tries to turn on the air conditioning at the indoor thermostat and if the outdoor unit runs in freezing weather it might be damaged by liquid refrigerant slugging in the compressor.

THose AC units do often include a crankcase heater to prevent liquid refrigerant slugging; that's why we leave power to the unit ON for 24 hours before actually asking the compressor motor to run at lower outdoor temperatures.

There are also "freeze protection kits" from Amana, Goodman, Supco, and others that provide an outdoor temperature sensor and that prevent the compressor from running at low outdoor temperatures.

Those can be retro-fitted to an A/C (i.e. not a heat pump) if needed. There are similar protection devices that can be fitted at the indoor coil to detect coil icing or freezing in that location, like the Amana FSK-01A kit.

Shown here: SUPCO freeze protection switch, opens at 35 degF.

On 2018-09-12 by (mod) -

Trung Tâm Kỹ Thuật Điện Lạnh Sudiho said:

Thank you very much for your post, this is very useful for me! We are providing the air conditioner repair service in Hanoi-Vietnam ... . Thanks to your blog that I was able to understand more about the air conditioner heat pump inspect and repair. Thank you very much! Looking forward to such blog posts!

On 2018-08-25 by (mod) - when is a refrigerant line cool or cold?

Abbie, it is normal for the suction line to be cold. If the high pressure refrigerant line is cool or cold and your system is a heat pump in heating mode, that would also be normal.

On 2018-08-25 by Arbbie

Discharge line cold

On 2018-08-15 by (mod) -

From an AC, probably not.

On 2018-08-11 by JLPetit

Is it a law about the max db

On 2018-08-09 by (mod) -

Robert at the live link found at the end of this page INDEX to RELATED ARTICLES: ARTICLE INDEX to AIR CONDITIONING & HEAT PUMPS

the index will give you articles on duct air flow improvement that includes diagnostics and that list common problems - i it's worth looking at accessible areas of the ductwork for something obvious like disconnections or crushed ductwork

On 2018-08-09 by Robert Fields

I have a home built in 2008. Dual zones. Upstairs AC works great in every room EXCEPT one vent in MBR which is likely at the end of the ducting.

I've kept this vent shut tight for last few years. Now I want the air to flow and nearly nothing comes out. Actually, what flow there is feels warm while the adjacent vents are all blowing cold air. Is there anything you can recommend I try to do prior to calling out a professional?

On 2018-08-05 by (mod) - signs of a bad motor start capacitor or bad electrical connection

Usually that signifies a bad start cap or a bad start cap wire or connector

On 2018-08-05 by Dwight

Goodman condenser unit, fan won't run unless you push it. I put a new 35/5 capactor on and same problem. I then put a new fan motor with separate capacitor on and it does same thing.

Voltage at cut off box is 246 and same at main contactor. With contactor engaged in have same voltage . Compressor starts and runs great. Fan motor is 2 wires to line and 2 brown wires to new capacitor. I even tried another new capacitor with the new motor. Help !!!!

On 2018-07-06 by (mod) - air conditioner blower to speed up right before it shuts off

That's not a symptom with which I'm familiar.

However some blower units use a multiple-speed fan. The control board could need adjustment (dip switch settings) or repair.

On 2018-07-06 by Rebecca

Is it normal for my air conditioner blower to speed up right before it shuts off?

On 2018-06-22 by (mod) - debris coming out of HVAC vents

Patti

I can't make an assessment from your note and photo, but certainly from what you describe there could be a risk that the air conditioning system is mold-contaminated and certainly there is damage somewhere if it's spitting out debris.

A more subtle but more dangerous problem can occur if debris is drawn right into the air handler or blower assembly where it could cause a jam-up, a blower motor overheat, and then a building fire.

You might pass on your concerns to your housing authority, in writing.

On 2018-06-22 by Patti

My ceiling has been leaking for 3-4 months. Housing Authority said they patched it. Now when my air conditioner blows threw vents, pieces of ceiling tile, ( insulation) comes out & is blacken,..

On 2018-06-20 by (mod) -

Low refrigerant, or malfunctioning thermal static expansion valve or something else

On 2018-06-19 by Dianna

had outside guardian ac replace old one, it has froze up twice. what could be problem?

On 2018-06-19 6 by (mod) -

Right - not even the service techs use consistent language. And yes, stay off the roof.

Check for reduced air flow at the supply registers

Check then for a dirty air filter

Check then for blocked, disconnected air ducts

On 2018-06-19 by Jill

And I just used the word "compressor" as being the problem when it could be the motor or something else (I read several things about it, but since I can't get on the roof, I can't check those things).

At this point, I just basically would like an opinion on whether or not I should continue to run it on auto until I have to have it replaced or would just letting it run continuously extend its life any? Thanks.

Thanks for the suggestion, but I don't know how to check things myself and part of it is on the roof, so if I decide to use the AC until it breaks down completely and I have to get a new one, am I better off leaving it on auto or just let it run all the time as far as if the compressor happens to be failing goes? I say that because now it seems to be having more trouble starting up after it has been off between cycles.

On 2018-06-07 by (mod) -

I would start at LOST COOLING CAPACITY

https://inspectapedia.com/aircond/Air_Conditioner_Diagnosis.php

for help in diagnosing and repairing the trouble ypu describe

Check air flow and temperaturee drop across the cooling coil.

On 2018-06-06 by Jill

My HVAC is around 15 years old. I have lived in my condo for 3 years now, so I wasn't living here when it was installed. It always reached the set AC temperature within a few minutes and I always leave the thermostat on "auto".

Recently it started taking hours to reach the set temperature and until it reaches that temperature, it doesn't turn off and on even though it's set on auto. It does run cold though. I also recently had the capacitor replaced. I asked the technician who replaced the capacitor why it's doing that, but he just said I need a new HVAC and couldn't tell me why it's doing that.

Do you happen to have any idea why it's taking so long to reach the set temperature? I don't want to have it replaced until it stops working altogether.

On 2018-06-02 by (mod) -

Marie

I can't say, in part because I don't know what coils, indoors or out, were cleaned nor by what methods.

But I note that electrical power is not necessary for some coil cleaning operations. The technician uses a foaming cleaner spray and cleans up the liquid that collects in the drip pan below.

On 2018-06-02 by marie

how do i know my contractor cleaned the coils with no power source electrical plug

On 2018-05-29 by (mod) -

Of course you could be right, but forgive us - we've a paucity of information on which to base any detailed guesses.

In general if a cabinet smells like musty water I'd look for leaks behind the cabinet or above or below it.

On 2018-05-29 by sally Brooks

I am not for sure but the smell is coming from my cabinet in the kitchen which is located next to the laundry room where the ac unit is located. But the room where the ac is doesnt smell It smells like old water or musty smell Could I be right?

On 2018-05-20 by (mod) -

Call for repair. The problem may be something as simple as obstructed airflow through the outdoor unit but it also could be a problem with a refrigerant control valve or low refrigerant.

On 2018-05-20 by Sarah Derrington

My Ac unit imdoors and outdoors is completey frozen what should i do besides turn unit off?

On 2018-05-19 by Minerva

I just bought a house that it Was bought and fix by a bank. They say they paint it and did other things, when I came to see it there was a smell kind of like paint so I though it was normal. After I move in I notice that the smell didn’t go away and that every time the ac is on the smell is stronger.

On 2018-05-15 by (mod) -

I would start with some on-site help from an HP AC duct installer or designer. It sounds as if the return air may be inadequate.

On 2018-05-15 by Andy

Last year I bought a 2 story home with 2 hvac units. The upstairs has 2 12x16 bedrooms on each end of a open balcony overlooking our living room that is open with 20ft high vaulted ceilings.

The upstairs unit has a 12x12 cold air return grill on the living room about the height between the floor joist with a bedroom closet on the other side which 12x12 return air grille in the ceiling and access to the attic where the air handler is located.

. It stays extremely hot upstairs in the bedrooms. Even though the ac runs constantly it's so hot and stuffy in the rooms. Is their anything I can do to help lower the temperature during the summer?

On 2018-04-12 by (mod) -

Jack

A homeowner can sometimes find and fix certain problems with air conditioners and heat pumps such as a blocked or dirty air filter or can diagnose others such as leaky, damaged ductwork.

But work that involves more complex diagnosis of a compressor motor, refrigerant metering devices, finding refrigerant leaks, or charging a system require special training and equipment.

That's also the case for installing new air conditioning equipment excepting portable systems such as a window A/C that is simply brought home, installed in a window with proper support, and plugged-in.

On 2018-04-12 by (mod) -

Jack said:

Thank you for a very useful article. I'm afraid to repair the air conditioner myself, so it's better to ask for help from specialists

. I had a bad experience trying to repair AC myself. I repaired it, but after a while it broke down anew, and it was not possible to repair it and it was necessary to change it completely.

If you are not sure what you can fix, better find a contractor. Well, now they can be ordered anywhere, even on the Internet you can choose by the price and reviews.

On 2016-12-08 by (mod) -

Anon: typically that'd be a short in the low voltage wiring or at a relay or on the circuit board.

On 2016-11-20 by Anonymous

ok I have airhandler that was burning up the transformer. I put a fuse in and took all low voltage wire loose.What is causing the fuse to blow

On 2016-11-18 by (mod) -

Kanchan see CONDENSATE DRAIN CONNECTED TO VENT PIPE at https://inspectapedia.com/aircond/Condensate_Drain_Problems.php#Vent

and you'll see there are sewer gas and other hazards.

On 2016-11-03 by Kanchan

Is it okay if the condensate line is connected to the plumbing drain vent pipe? We came to know about this in our inspection.

We got one house inspected and we saw that the condensate line is connected to plumbing drain

On 2016-10-25 by (mod) -

Perhaps this is a system looking for backup heat and your backup heat is off or inoperative.

On 2016-10-25 by Donny & Phyllis Bailey

checked all fuses all good is it one of those small cynoyds or what I turned it on once worked well then when I needed it I get air but no heat

On 2016-10-24 by (mod) -

I'm not quite sure what you've found, as we don't have the whole picture. But often buildings are constructed with a pair of return air inlets in the top floor ceiling, often at a stairwell. Why two? To provide adequate total return air inlet without cutting a ceiling joist or to locate return air inlets in two different spots.

On 2016-10-24 by

i just inspected a 2016 new home and it had two open mechanical grills mounted high in the attic blowing cool air - it does have a temperature control system and a de-humidifier- why is there duct cooling the air in the attic ?

On 2016-10-15 by Steve

My tile floor is ice cold along a direct line from my AC units outside to my air handler inside. Do you suppose the line is leaking or just improperly insulated?

On 2016-08-26 by marcos lopez

what is IFC stand for on diagnostic problem chart?

...

Continue reading at AIR CONDITIONING & HEAT PUMP SYSTEMS or select a topic from the closely-related articles below, or see the complete ARTICLE INDEX.

Or see AIR CONDITIONING & HEAT PUMP SYSTEM FAQs-2 - more-recent Q&A about troubleshooting and fixing an air conditioner or heat pump

Or see these

Recommended Articles

- AIR HANDLER / BLOWER UNITS - home

- COMPRESSOR / CONDENSER REPAIR - home